MicroMod Environmental Function Board Hookup Guide a learn.sparkfun.com tutorial

Available online at: http://sfe.io/t2001

Introduction

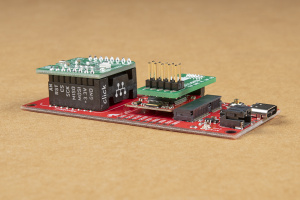

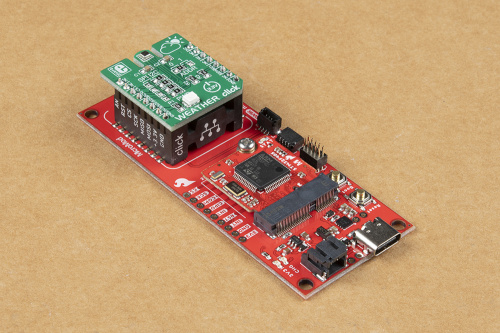

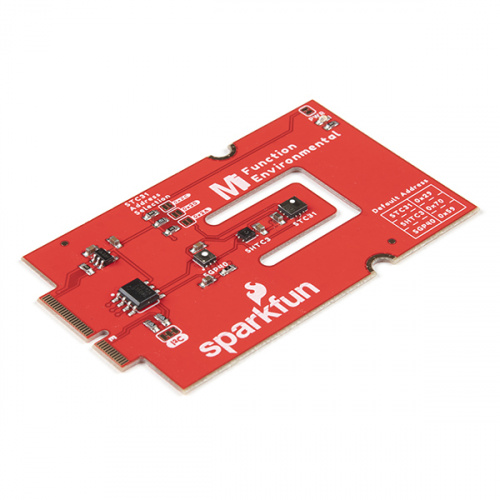

The SparkFun MicroMod Environmental Function Board adds additional sensing options to the MicroMod Processor Boards. This function board includes three sensors to monitor air quality (SGP40), humidity & temperature (SHTC3), and CO2 concentrations (STC31) in your indoor environment. To make it even easier to use, all communication is over the MicroMod's I2C bus! In this tutorial, we will go over how to connect the board and read the sensors.

Required Materials

To follow along with this tutorial, you will need the following materials at a minimum. You may not need everything though depending on what you have. Add it to your cart, read through the guide, and adjust the cart as necessary.

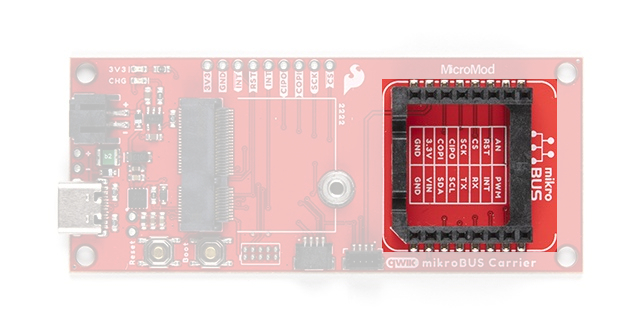

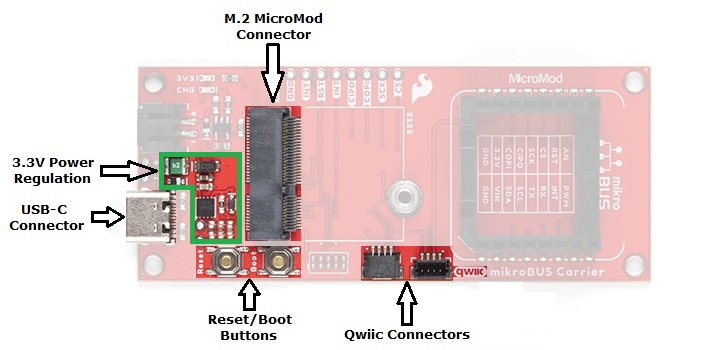

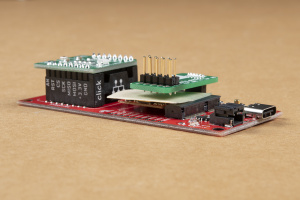

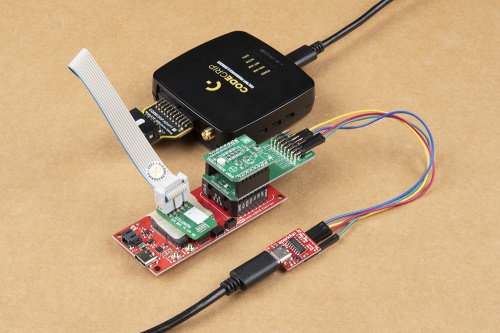

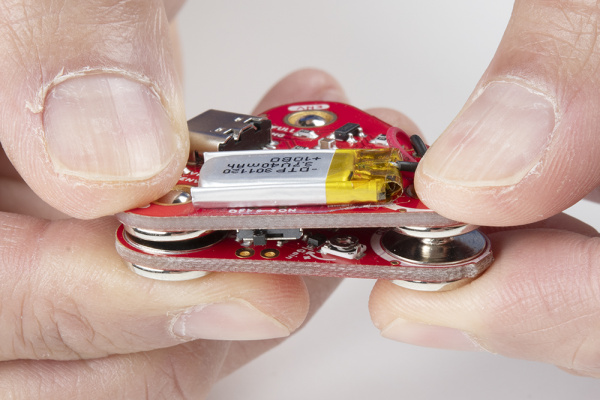

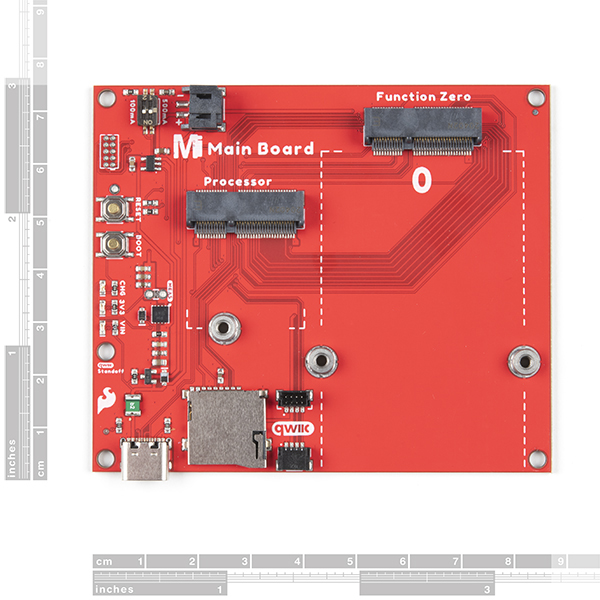

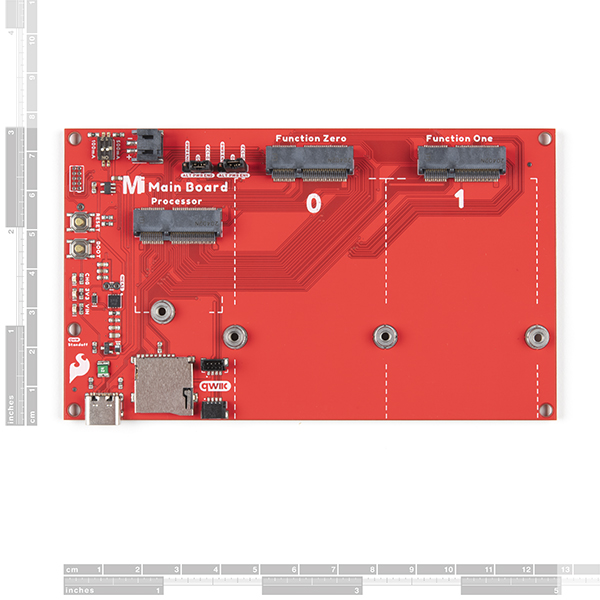

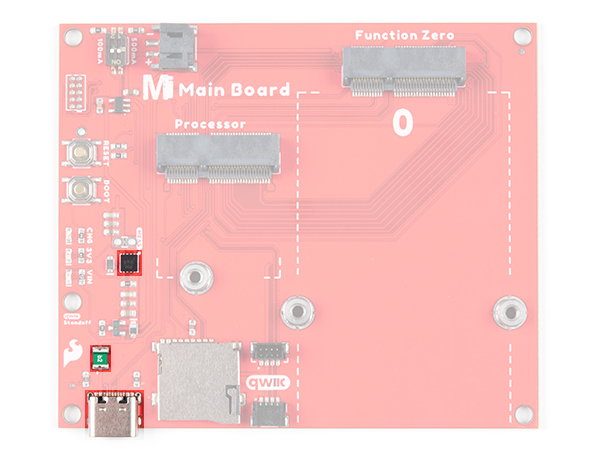

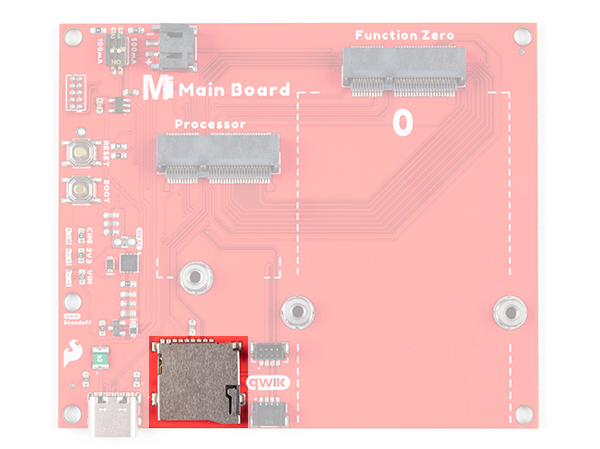

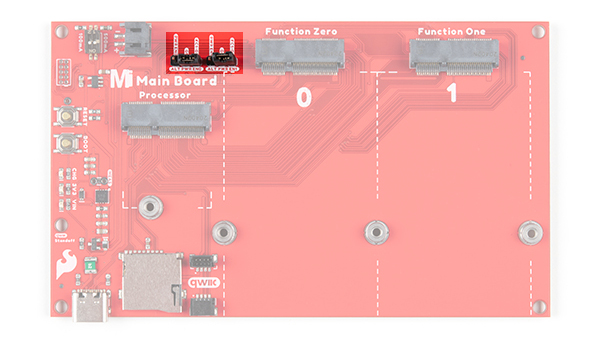

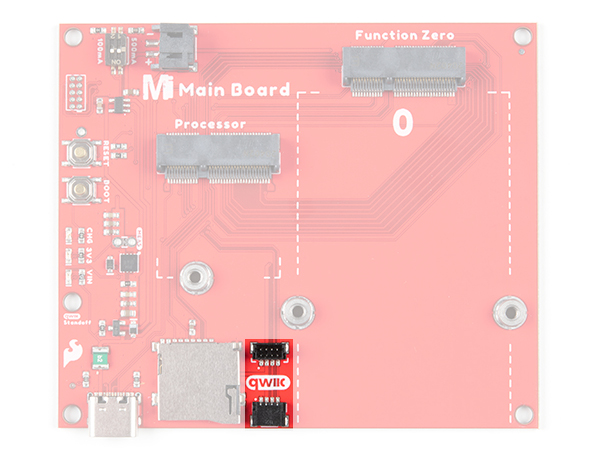

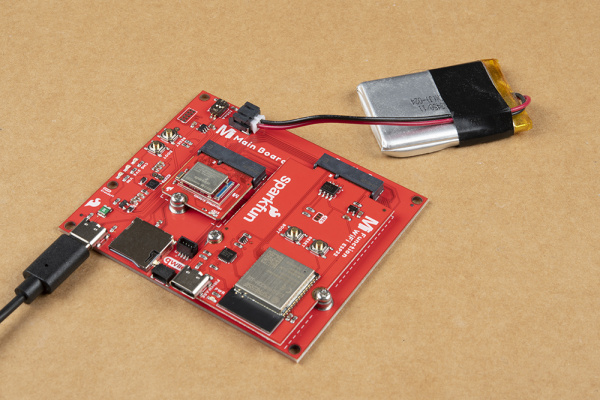

MicroMod Main Board

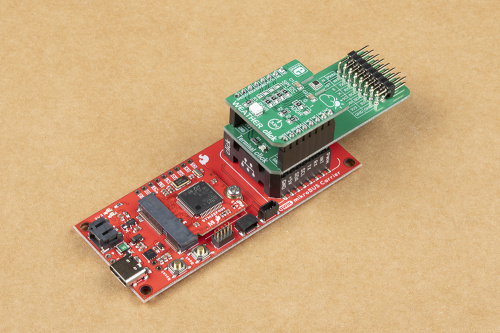

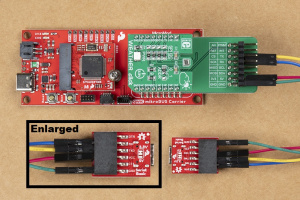

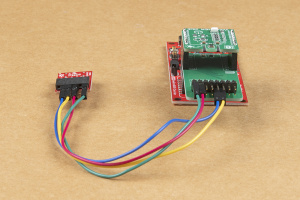

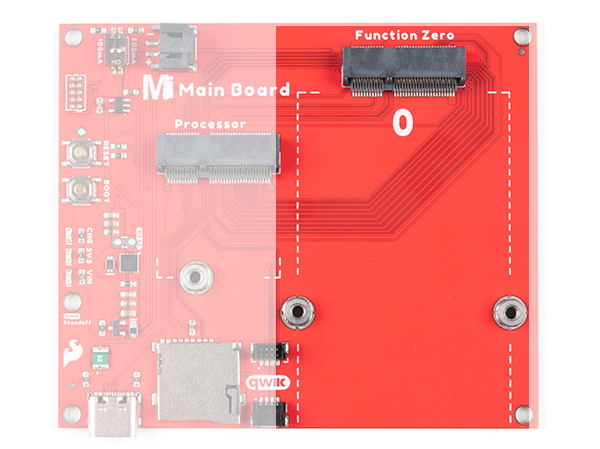

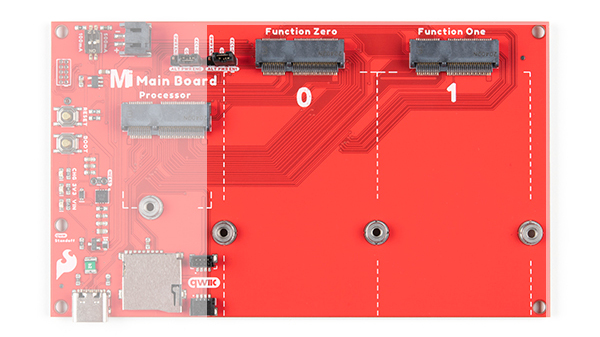

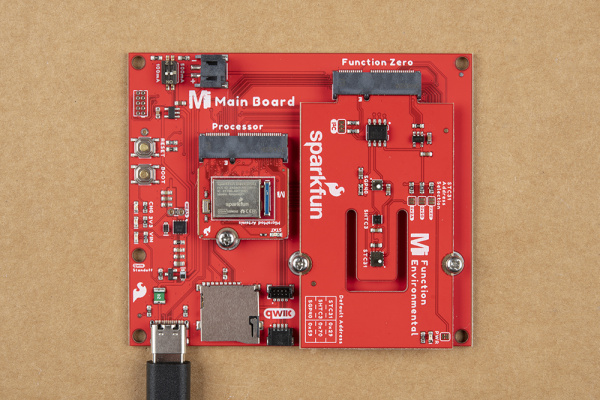

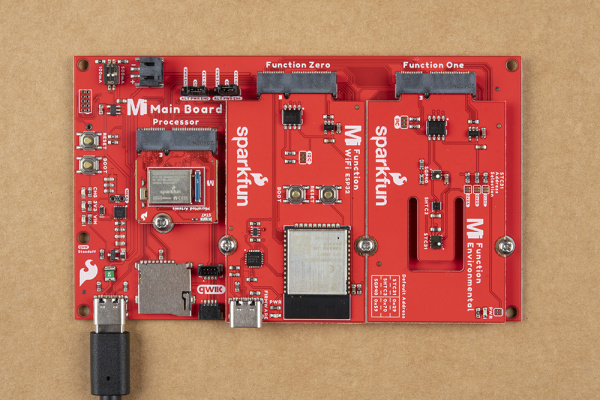

To hold the processor and function boards, you will need one Main board. Depending on your application, you may choose to have either one or two function boards.

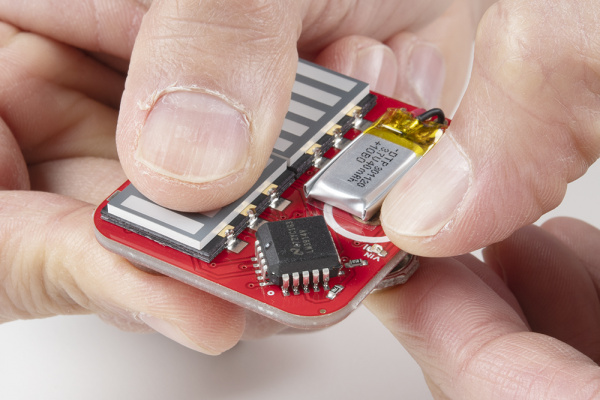

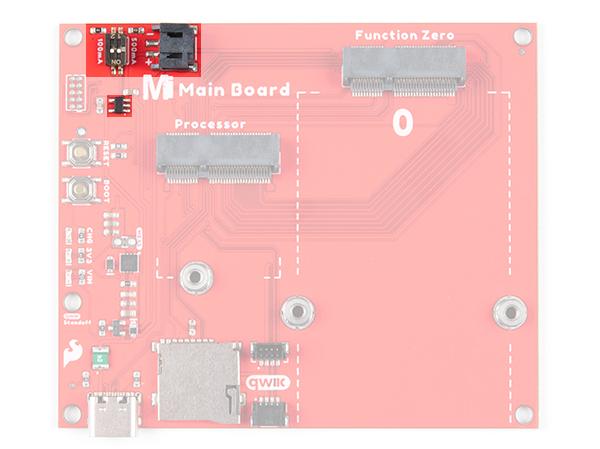

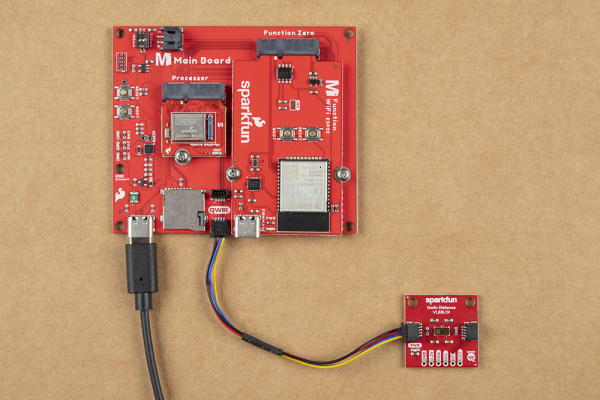

MicroMod Function Board

To add additional functionality to your Processor Board, you'll want to include one or two function boards when connecting them to the Main Board. Besides the MicroMod Environmental Function Board which this tutorial is focused on, you may descide to add the WiFi Function Board to the mix. Make sure to adjust the cart and include the MicroMod Main Board - Double as opposed to the Single when using two Function Boards. Check out the SparkFun catalog for other function boards.

Tools

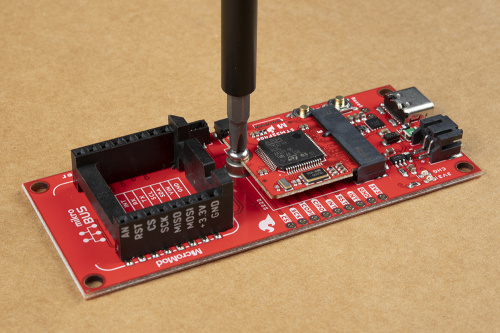

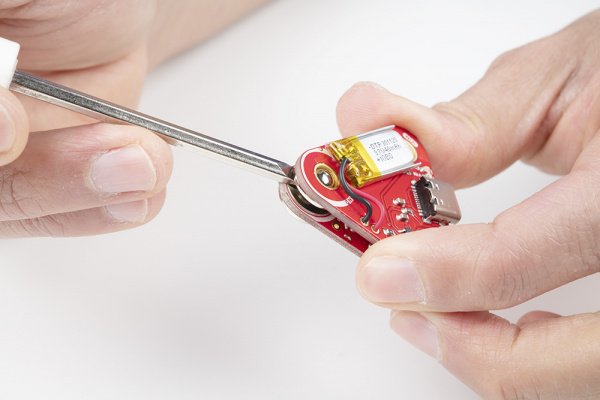

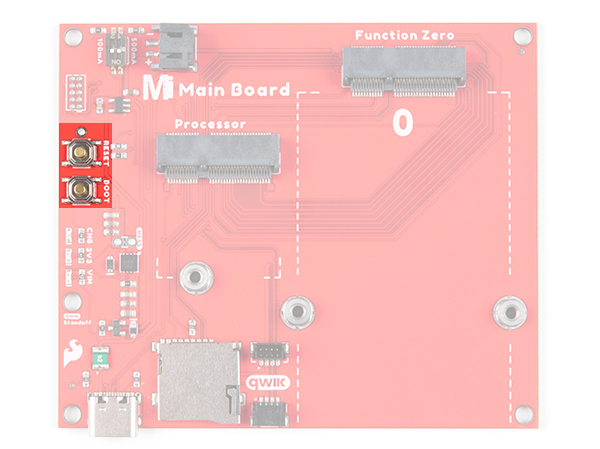

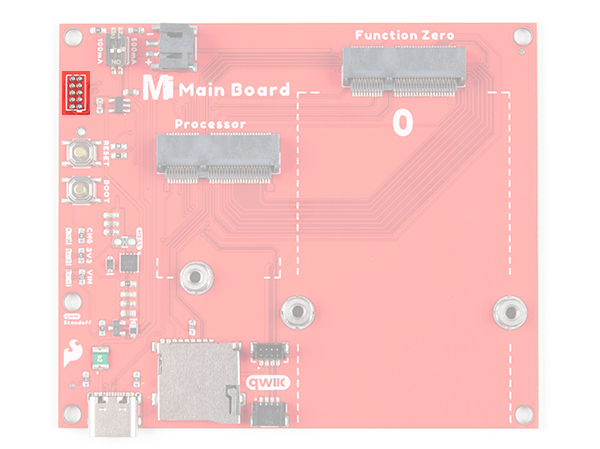

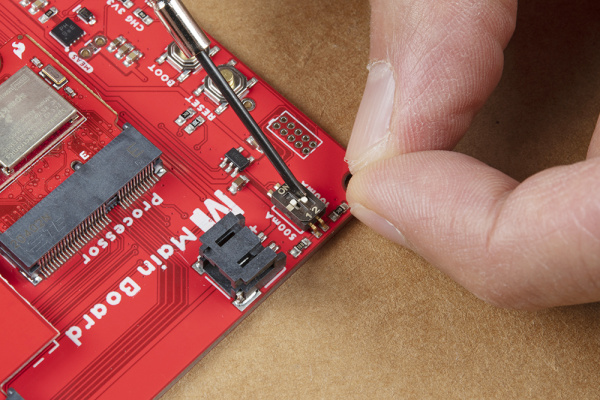

You will need a screw driver to secure the Processor and Function boards.

Suggested Reading

If you aren't familiar with the MicroMod ecosystem, we recommend reading here for an overview.

|

| MicroMod Ecosystem |

If you aren’t familiar with the following concepts, we also recommend checking out a few of these tutorials before continuing. Make sure to check the respective hookup guides for your processor board and function board to ensure that you are installing the correct USB-to-serial converter. You may also need to follow additional instructions that are not outlined in this tutorial to install the appropriate software.

What is an Arduino?

Installing Arduino IDE

How to Install CH340 Drivers

SparkFun Humidity Sensor Breakout - SHTC3 (Qwiic) Hookup Guide

Getting Started with MicroMod

Air Quality Sensor - SGP40 (Qwiic) Hookup Guide

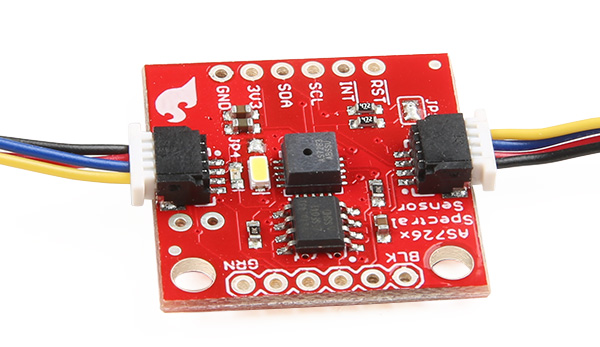

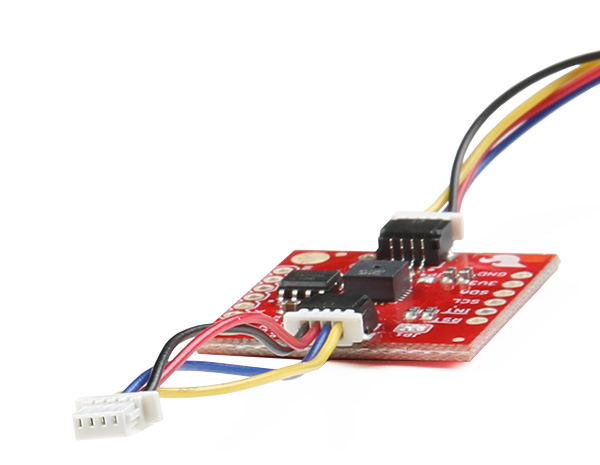

Hardware Overview

This section goes over the important features on the MicroMod Environmental Function Board. Of course, we recommend checking out the Resources and Going Further for more information on each sensor.

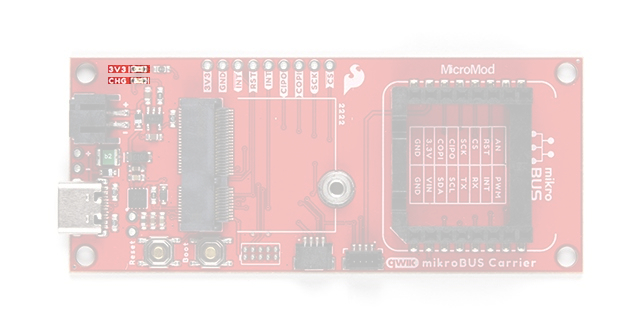

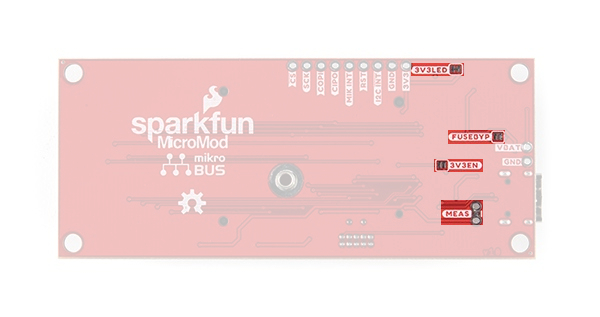

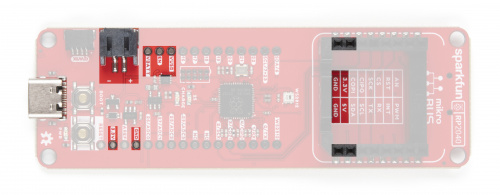

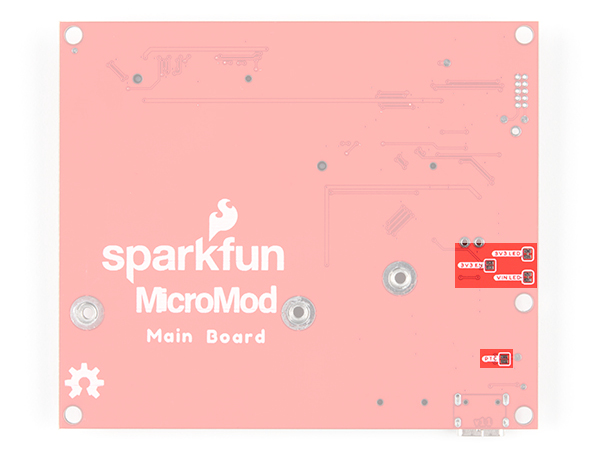

Power

To power the board, you will need to apply power to a SparkFun Main Board. Power applied will connect to the Function Board's VIN pin, which will be regulated down for the rest of the board with the AP2112 3.3V/600mA voltage regulator.

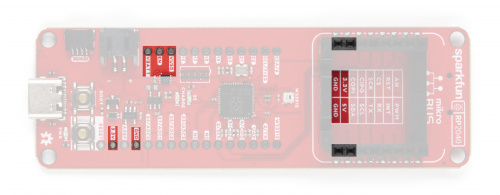

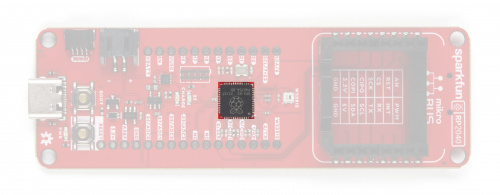

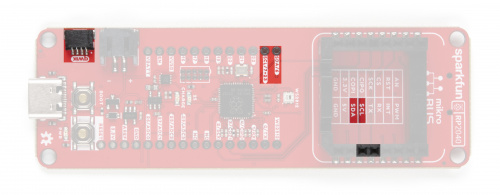

SGP40

The board includes the Sensirion SGP40 sensor IC which measures air quality. The reserved I2C address for the SGP40 is 0x59. For easy reference, the default address for the SGP40 is labeled on the board.

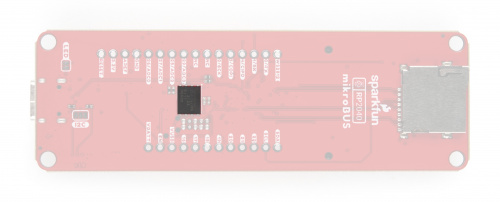

SHTC3

The board includes the Sensirion SHTC3 sensor IC which measures humidity and temperature. The reserved I2C address for the SHTC3 is 0x70. For easy reference, the default address for the SHTC3 is labeled on the board.

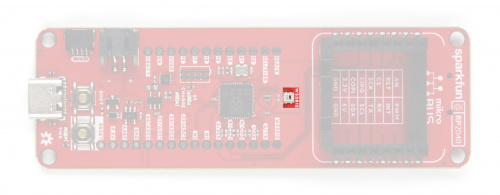

STC31

The board includes the Sensirion STC31 sensor IC which measures CO2 concentrations in N2 and CO2 in air. The reserved I2C address for the STC31 is 0x29. For easy reference, the default address for the STC31 is labeled on the board.

EEPROM

The board includes an I2C EEPROM. Unfortunately, this is not available for the user and was meant to hold board specific information.

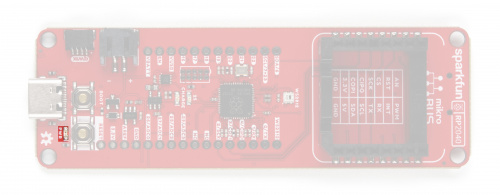

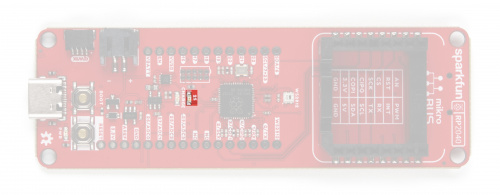

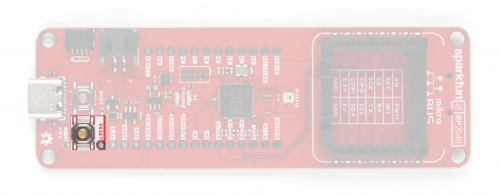

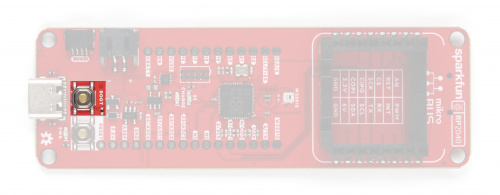

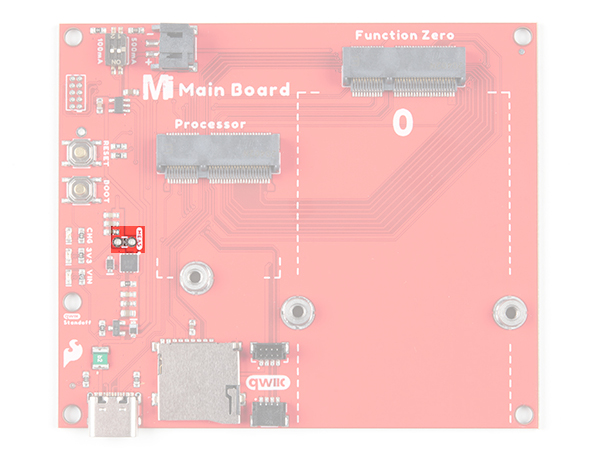

LED

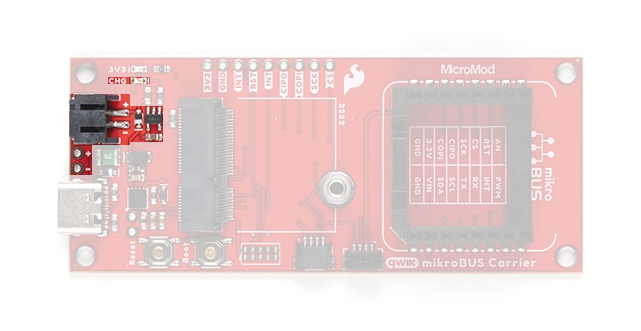

There is one LED to indicate when there is power available. You can disable the LED with the PWR jumper

Jumpers

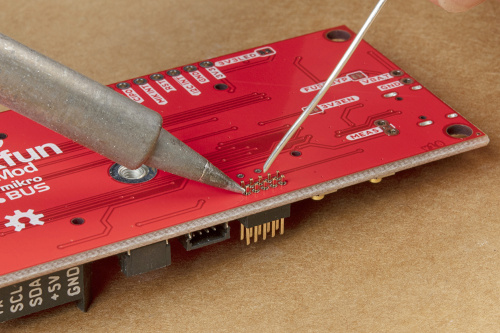

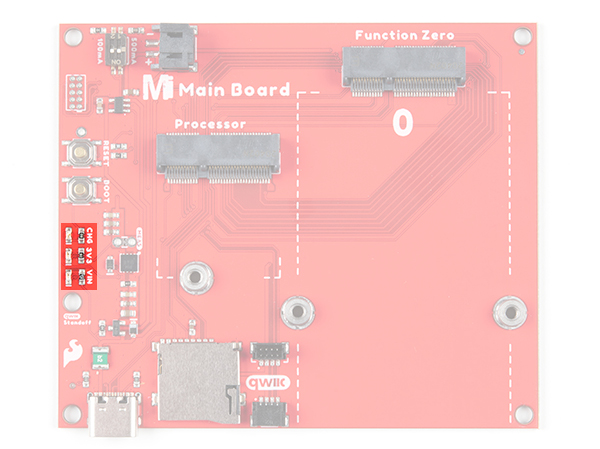

The following jumpers are included to configure the board.

- PWR - By default, the jumper with the label

PWRis closed. This jumper connects the 3.3V line and LED. Cutting this jumper will disable the LED. - I2C Pull-up Resistors - By default, this three way jumper labeled

I2Cis closed and connects two pull-up resistors to the I2C data lines. If you have many devices on your I2C data lines, then you may consider cutting these two jumpers. - STC31 Address Selection - There are three jumpers available on the board to adjust the STC31's address. By default, the jumpers are open. The alternative addresses for the sensor are 0x2A, 0x2B, and 0x2C. To select the address, you will need to close the jumper by adding a solder blob to one of the solder jumpers.

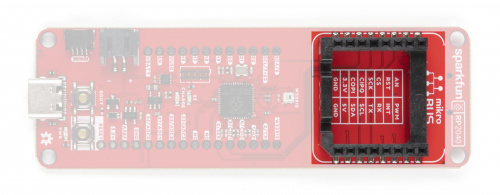

MicroMod Function Board Pinout

Depending on your window size, you may need to use the horizontal scroll bar at the bottom of the table to view the additional pin functions. Note that the M.2 connector pins on opposing sides are offset from each other as indicated by the bottom pins where it says (Not Connected)*. There is no connection to pins that have a "-" under the primary function.

| AUDIO | UART | GPIO/BUS | I2C | SDIO | SPI0 | Dedicated |

| Function | Bottom Pin | Top Pin | Function | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||||||

| 3.3V | 74 | 73 | G5 / BUS5 | ||||||

| RTC_3V_BATT | 72 | 71 | G6 / BUS6 | ||||||

| SPI_CS1# | SDIO_DATA3 (I/O) | 70 | 69 | G7 / BUS7 | |||||

| SDIO_DATA2 (I/O) | 68 | 67 | G8 | ||||||

| SDIO_DATA1 (I/O) | 66 | 65 | G9 | ADC_D- | CAM_HSYNC | ||||

| SPI_CIPO1 | SDIO_DATA0 (I/O) | 64 | 63 | G10 | ADC_D+ | CAM_VSYNC | |||

| SPI COPI1 | SDIO_CMD (I/O) | 62 | 61 | SPI_CIPO (I) | |||||

| SPI SCK1 | SDIO_SCK (O) | 60 | 59 | SPI_COPI (O) | LED_DAT | ||||

| AUD_MCLK (O) | 58 | 57 | SPI_SCK (O) | LED_CLK | |||||

| CAM_MCLK | PCM_OUT | I2S_OUT | AUD_OUT | 56 | 55 | SPI_CS# | |||

| CAM_PCLK | PCM_IN | I2S_IN | AUD_IN | 54 | 53 | I2C_SCL1 (I/O) | |||

| PDM_DATA | PCM_SYNC | I2S_WS | AUD_LRCLK | 52 | 51 | I2C_SDA1 (I/O) | |||

| PDM_CLK | PCM_CLK | I2S_SCK | AUD_BCLK | 50 | 49 | BATT_VIN / 3 (I - ADC) (0 to 3.3V) | |||

| G4 / BUS4 | 48 | 47 | PWM1 | ||||||

| G3 / BUS3 | 46 | 45 | GND | ||||||

| G2 / BUS2 | 44 | 43 | CAN_TX | ||||||

| G1 / BUS1 | 42 | 41 | CAN_RX | ||||||

| G0 / BUS0 | 40 | 39 | GND | ||||||

| A1 | 38 | 37 | USBHOST_D- | ||||||

| GND | 36 | 35 | USBHOST_D+ | ||||||

| A0 | 34 | 33 | GND | ||||||

| PWM0 | 32 | 31 | Module Key | ||||||

| Module Key | 30 | 29 | Module Key | ||||||

| Module Key | 28 | 27 | Module Key | ||||||

| Module Key | 26 | 25 | Module Key | ||||||

| Module Key | 24 | 23 | SWDIO | ||||||

| UART_TX2 (O) | 22 | 21 | SWDCK | ||||||

| UART_RX2 (I) | 20 | 19 | UART_RX1 (I) | ||||||

| CAM_TRIG | D1 | 18 | 17 | UART_TX1 (0) | |||||

| I2C_INT# | 16 | 15 | UART_CTS1 (I) | ||||||

| I2C_SCL (I/0) | 14 | 13 | UART_RTS1 (O) | ||||||

| I2C_SDA (I/0) | 12 | 11 | BOOT (I - Open Drain) | ||||||

| D0 | 10 | 9 | USB_VIN | ||||||

| SWO | G11 | 8 | 7 | GND | |||||

| RESET# (I - Open Drain) | 6 | 5 | USB_D- | ||||||

| 3.3V_EN | 4 | 3 | USB_D+ | ||||||

| 3.3V | 2 | 1 | GND | ||||||

| Alternative Function | Primary Function | Bottom Pin | Top Pin | Primary Function | Alternative Function |

|---|---|---|---|---|---|

| (Not Connected) | 75 | GND | |||

| VIN | 74 | 73 | 3.3V | ||

| VIN | 72 | 71 | Power EN | ||

| - | 70 | 69 | - | ||

| - | 66 | 65 | - | ||

| - | 64 | 63 | - | ||

| - | 62 | 61 | - | ||

| - | 60 | 59 | - | ||

| - | 58 | 57 | - | ||

| - | 56 | 55 | - | ||

| - | 54 | 53 | - | ||

| - | 52 | 51 | - | ||

| - | 50 | 49 | - | ||

| - | 48 | 47 | - | ||

| - | 46 | 45 | GND | ||

| - | 44 | 43 | - | ||

| - | 42 | 41 | - | ||

| - | 40 | 39 | GND | ||

| - | 38 | 37 | - | ||

| EEPROM_A0 | 36 | 35 | - | ||

| EEPROM_A1 | 34 | 33 | GND | ||

| EEPROM_A2 | 32 | 31 | Module Key | ||

| Module Key | 30 | 29 | Module Key | ||

| Module Key | 28 | 27 | Module Key | ||

| Module Key | 26 | 25 | Module Key | ||

| Module Key | 24 | 23 | - | ||

| - | 22 | 21 | I2C_SCL | ||

| - | 20 | 19 | I2C_SDA | ||

| - | 18 | 17 | - | ||

| - | 16 | 15 | - | ||

| - | 14 | 13 | - | ||

| - | 12 | 11 | - | ||

| - | 10 | 9 | - | ||

| - | 8 | 7 | - | ||

| - | 6 | 5 | - | ||

| - | 4 | 3 | - | ||

| - | 2 | 1 | GND |

| Signal Group | Signal | I/O | Description | Voltage | Power | 3.3V | I | 3.3V Source | 3.3V |

|---|---|---|---|---|

| GND | Return current path | 0V | ||

| USB_VIN | I | USB VIN compliant to USB 2.0 specification. Connect to pins on processor board that require 5V for USB functionality | 4.8-5.2V | |

| RTC_3V_BATT | I | 3V provided by external coin cell or mini battery. Max draw=100μA. Connect to pins maintaining an RTC during power loss. Can be left NC. | 3V | |

| 3.3V_EN | O | Controls the carrier board's main voltage regulator. Voltage above 1V will enable 3.3V power path. | 3.3V | |

| BATT_VIN/3 | I | Carrier board raw voltage over 3. 1/3 resistor divider is implemented on carrier board. Amplify the analog signal as needed for full 0-3.3V range | 3.3V | |

| Reset | Reset | I | Input to processor. Open drain with pullup on processor board. Pulling low resets processor. | 3.3V |

| Boot | I | Input to processor. Open drain with pullup on processor board. Pulling low puts processor into special boot mode. Can be left NC. | 3.3V | |

| USB | USB_D± | I/O | USB Data ±. Differential serial data interface compliant to USB 2.0 specification. If UART is required for programming, USB± must be routed to a USB-to-serial conversion IC on the processor board. | |

| USB Host | USBHOST_D± | I/O | For processors that support USB Host Mode. USB Data±. Differential serial data interface compliant to USB 2.0 specification. Can be left NC. | |

| CAN | CAN_RX | I | CAN Bus receive data. | 3.3V |

| CAN_TX | O | CAN Bus transmit data. | 3.3V | |

| UART | UART_RX1 | I | UART receive data. | 3.3V |

| UART_TX1 | O | UART transmit data. | 3.3V | |

| UART_RTS1 | O | UART ready to send. | 3.3V | |

| UART_CTS1 | I | UART clear to send. | 3.3V | |

| UART_RX2 | I | 2nd UART receive data. | 3.3V | |

| UART_TX2 | O | 2nd UART transmit data. | 3.3V | |

| I2C | I2C_SCL | I/O | I2C clock. Open drain with pullup on carrier board. | 3.3V |

| I2C_SDA | I/O | I2C data. Open drain with pullup on carrier board | 3.3V | |

| I2C_INT# | I | Interrupt notification from carrier board to processor. Open drain with pullup on carrier board. Active LOW | 3.3V | |

| I2C_SCL1 | I/O | 2nd I2C clock. Open drain with pullup on carrier board. | 3.3V | |

| I2C_SDA1 | I/O | 2nd I2C data. Open drain with pullup on carrier board. | 3.3V | |

| SPI | SPI_COPI | O | SPI Controller Output/Peripheral Input. | 3.3V |

| SPI_CIPO | I | SPI Controller Input/Peripheral Output. | 3.3V | |

| SPI_SCK | O | SPI Clock. | 3.3V | |

| SPI_CS# | O | SPI Chip Select. Active LOW. Can be routed to GPIO if hardware CS is unused. | 3.3V | |

| SPI/SDIO | SPI_SCK1/SDIO_CLK | O | 2nd SPI Clock. Secondary use is SDIO Clock. | 3.3V |

| SPI_COPI1/SDIO_CMD | I/O | 2nd SPI Controller Output/Peripheral Input. Secondary use is SDIO command interface. | 3.3V | |

| SPI_CIPO1/SDIO_DATA0 | I/O | 2nd SPI Peripheral Input/Controller Output. Secondary use is SDIO data exchange bit 0. | 3.3V | |

| SDIO_DATA1 | I/O | SDIO data exchange bit 1. | 3.3V | |

| SDIO_DATA2 | I/O | SDIO data exchange bit 2. | 3.3V | |

| SPI_CS1/SDIO_DATA3 | I/O | 2nd SPI Chip Select. Secondary use is SDIO data exchange bit 3. | 3.3V | |

| Audio | AUD_MCLK | O | Audio master clock. | 3.3V |

| AUD_OUT/PCM_OUT/I2S_OUT/CAM_MCLK | O | Audio data output. PCM synchronous data output. I2S serial data out. Camera master clock. | 3.3V | |

| AUD_IN/PCM_IN/I2S_IN/CAM_PCLK | I | Audio data input. PCM syncrhonous data input. I2S serial data in. Camera periphperal clock. | 3.3V | |

| AUD_LRCLK/PCM_SYNC/I2S_WS/PDM_DATA | I/O | Audio left/right clock. PCM syncrhonous data SYNC. I2S word select. PDM data. | 3.3V | |

| AUD_BCLK/PCM_CLK/I2S_CLK/PDM_CLK | O | Audio bit clock. PCM clock. I2S continuous serial clock. PDM clock. | 3.3V | |

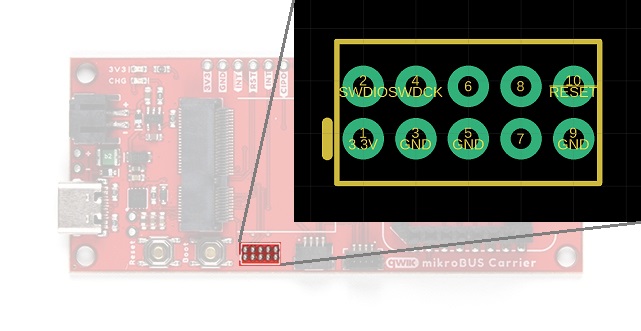

| SWD | SWDIO | I/O | Serial Wire Debug I/O. Connect if processor board supports SWD. Can be left NC. | 3.3V |

| SWDCK | I | Serial Wire Debug clock. Connect if processor board supports SWD. Can be left NC. | 3.3V | |

| ADC | A0 | I | Analog to digital converter 0. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V |

| A1 | I | Analog to digital converter 1. Amplify the analog signal as needed to enable full 0-3.3V range. | 3.3V | |

| PWM | PWM0 | O | Pulse width modulated output 0. | 3.3V |

| PWM1 | O | Pulse width modulated output 1. | 3.3V | |

| Digital | D0 | I/O | General digital input/output pin. | 3.3V |

| D1/CAM_TRIG | I/O | General digital input/output pin. Camera trigger. | 3.3V | |

| General/Bus | G0/BUS0 | I/O | General purpose pins. Any unused processor pins should be assigned to Gx with ADC + PWM capable pins given priority (0, 1, 2, etc.) positions. The intent is to guarantee PWM, ADC and Digital Pin functionality on respective ADC/PWM/Digital pins. Gx pins do not guarantee ADC/PWM function. Alternative use is pins can support a fast read/write 8-bit or 4-bit wide bus. | 3.3V |

| G1/BUS1 | I/O | 3.3V | ||

| G2/BUS2 | I/O | 3.3V | ||

| G3/BUS3 | I/O | 3.3V | ||

| G4/BUS4 | I/O | 3.3V | ||

| G5/BUS5 | I/O | 3.3V | ||

| G6/BUS6 | I/O | 3.3V | ||

| G7/BUS7 | I/O | 3.3V | ||

| G8 | I/O | General purpose pin | 3.3V | |

| G9/ADC_D-/CAM_HSYNC | I/O | Differential ADC input if available. Camera horizontal sync. | 3.3V | |

| G10/ADC_D+/CAM_VSYNC | I/O | Differential ADC input if available. Camera vertical sync. | 3.3V | |

| G11/SWO | I/O | General purpose pin. Serial Wire Output | 3.3V |

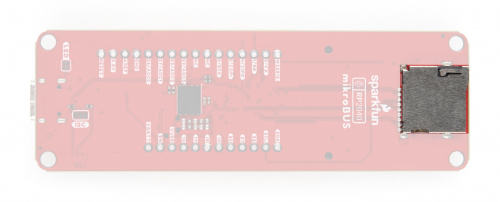

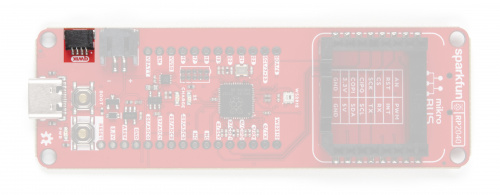

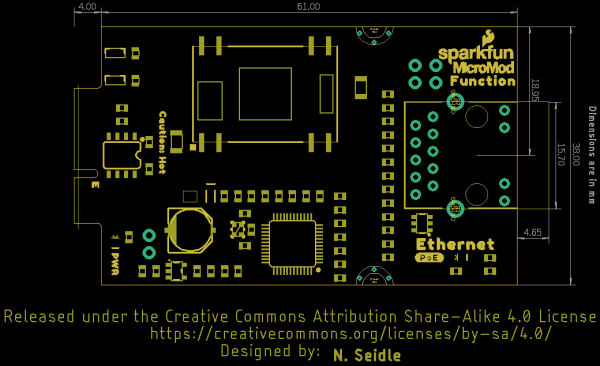

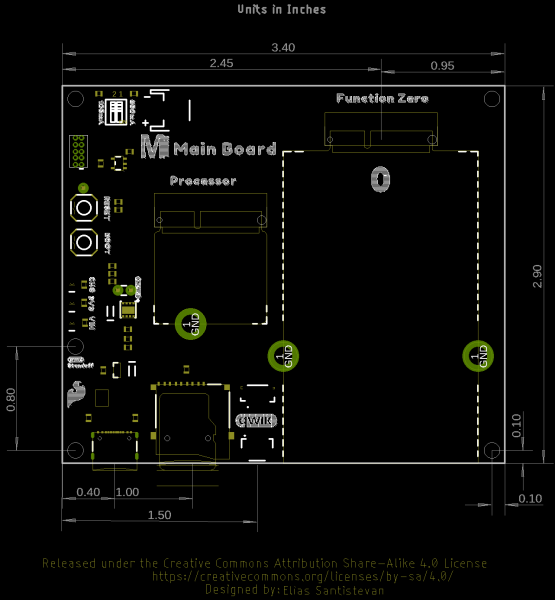

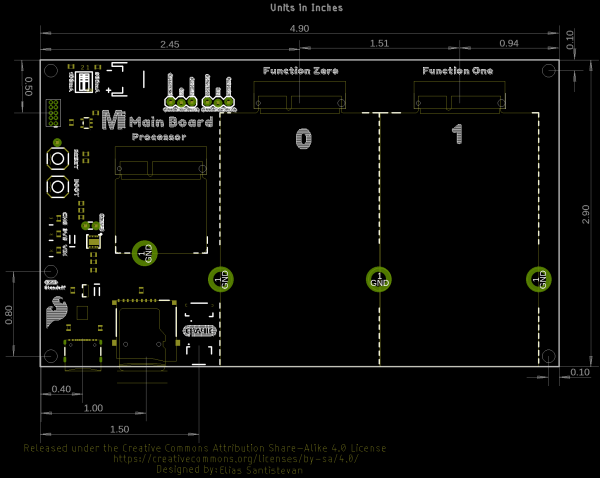

Board Dimensions

The board uses the standard MicroMod Function Board size which measures about 1.50"x2.56".

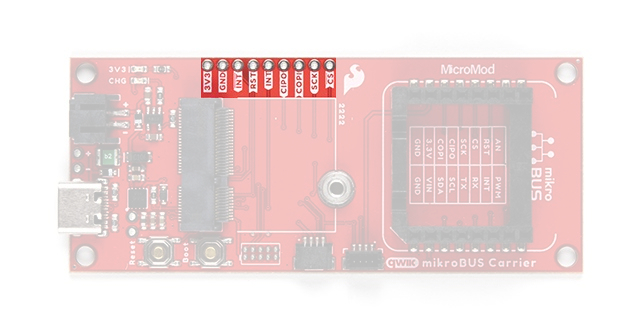

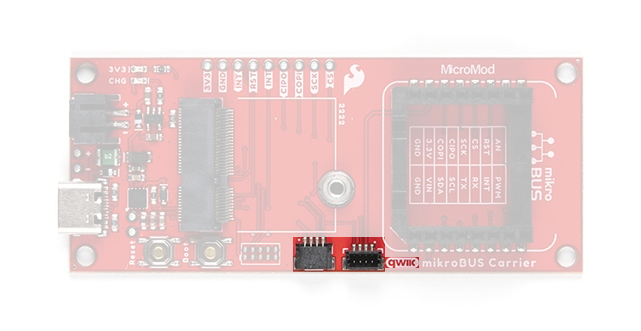

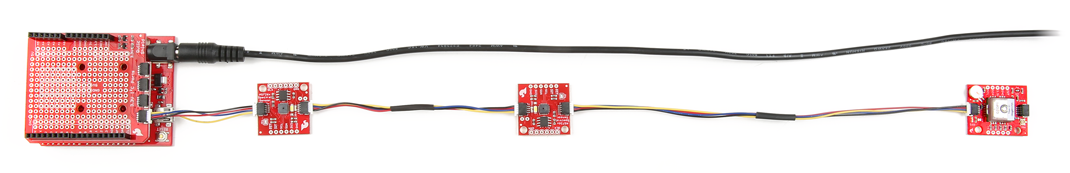

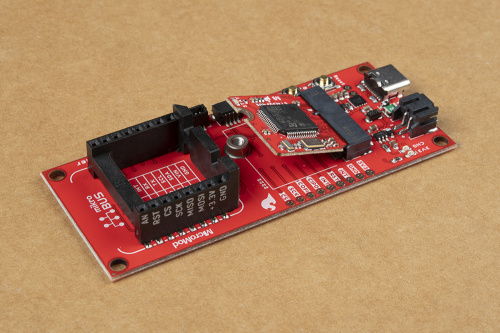

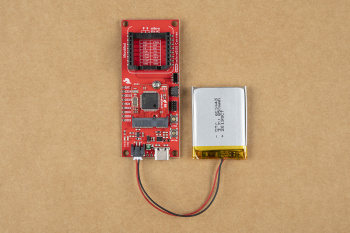

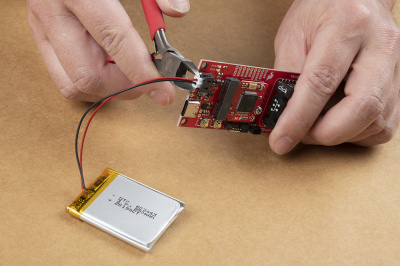

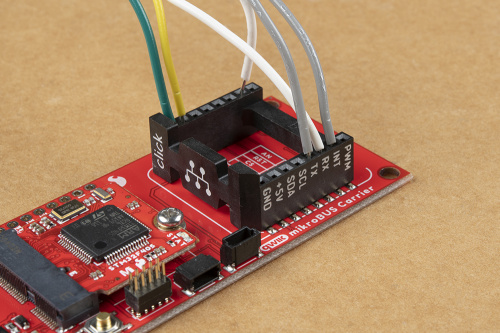

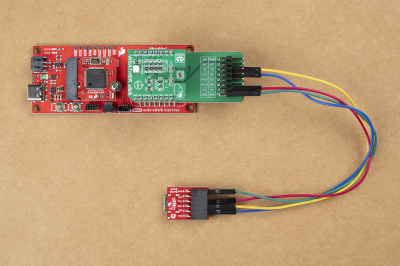

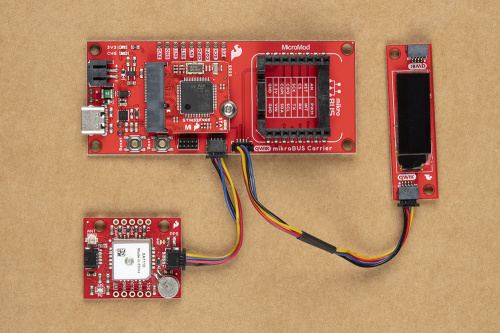

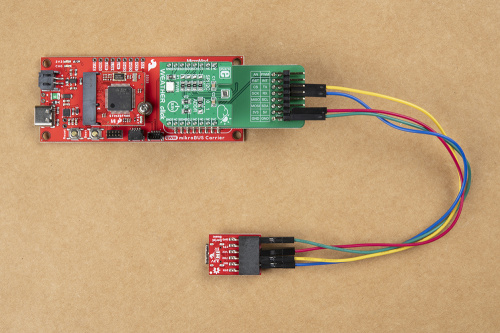

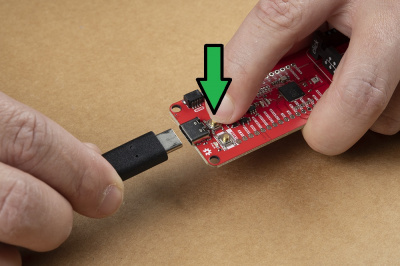

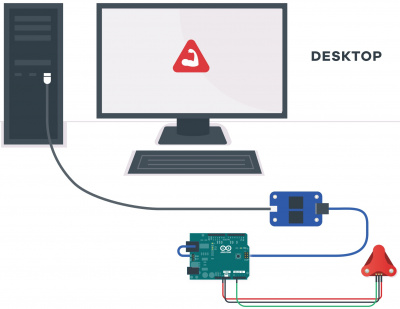

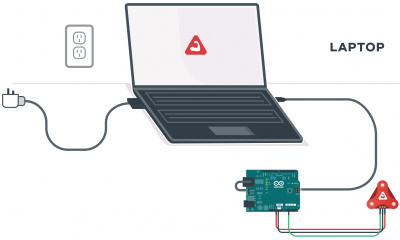

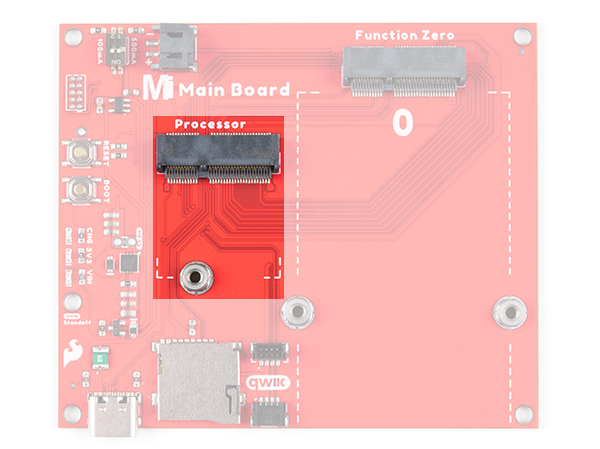

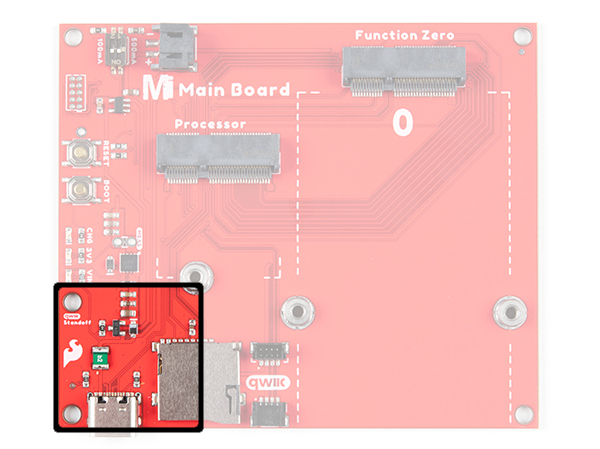

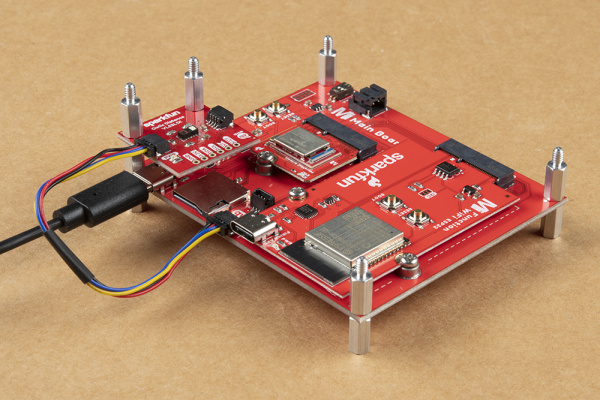

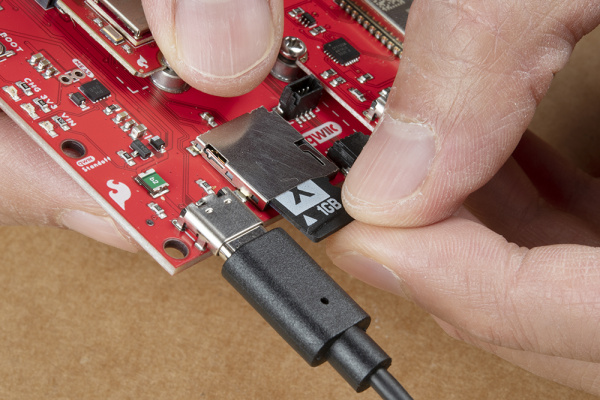

Hardware Hookup

If you have not already, make sure to check out the Getting Started with MicroMod: Hardware Hookup for information on inserting your Processor and Function Boards to the Main Board.

Getting Started with MicroMod

October 21, 2020

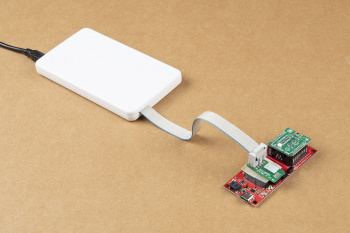

After securing the Processor and Function Board to the Main Board, your setup should look like the image below. Connect a USB Type C Cable to begin programming your Processor Board. In this case, we used the MicroMod Main Board - Single, MicroMod Artemis Processor, and MicroMod Environmental Function Board.

Software Installation

Arduino Board Definitions and Driver

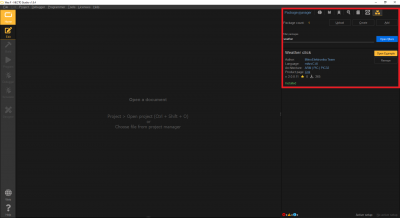

We'll assume that you installed the necessary board files and drivers for your Processor Board. In this case, we used the MicroMod Artemis Processor Board which uses the CH340 USB-to-serial converter. If you are using a Processor Board, make sure to check out its hookup guide for your Processor Board.

Installing Board Definitions in the Arduino IDE

September 9, 2020

MicroMod Artemis Processor Board Hookup Guide

October 21, 2020

How to Install CH340 Drivers

August 6, 2019

Arduino Library

The SparkFun SGP40, SHTC3, and STC3X Arduino libraries can be downloaded with the Arduino library manager by searching 'SparkFun SGP40,' 'SHTC3,' and 'STC3X'. Or you can grab the zip here from each respective GitHub repository (SGP40, SHTC3, STC3X) to manually install:

SparkFun SHTC3 Arduino Library (ZIP)

SparkFun STC3X Arduino Library (ZIP)

Arduino Examples

Example 1: Reading SHTC3, STC31, and SGP40

Below is the combined example to read SHTC3, STC31, and SGP40. If you have not already, select your Board (in this case the MicroMod Artemis), and associated COM port. Copy and paste the code below in your Arduino IDE. Hit the upload button and set the serial monitor to 115200 baud.

language:c

/******************************************************************************

WRITTEN BY: Ho Yun "Bobby" Chan

@ SparkFun Electronics

DATE: 10/19/2021

GITHUB REPO: https://github.com/sparkfun/MicroMod_Environmental_Sensor_Function_Board

DEVELOPMENT ENVIRONMENT SPECIFICS:

Firmware developed using Arduino IDE v1.8.12

========== DESCRIPTION==========

This example code combines example codes from the SHTC3, STC31, and SGP40 libraries.

Most of the steps to obtain the measurements are the same as the example code.

Generic object names were renamed (e.g. mySensor => mySGP40 and mySTC3x).

Example 1: Basic Relative Humidity and Temperature Readings w/ SHTC3; Written by Owen Lyke

Example 2: PHT (SHTC3) Compensated CO2 Readings w/ STC31; Written by Paul Clark and based on earlier code by Nathan Seidle

Example 1: Basic VOC Index w/ SGP40; Written by Paul Clark

Open a Serial Monitor at 115200 baud to view the readings!

Note: You may need to wait about ~5 minutes after starting up the code before VOC index

has any values.

========== HARDWARE CONNECTIONS ==========

MicroMod Artemis Processor Board => MicroMod Main Board => MicroMod Environmental Function Board (with SHTC3, STC31, and SGP40)

Feel like supporting open source hardware?

Buy a board from SparkFun!

MicroMod MicroMod Artemis Processor | https://www.sparkfun.com/products/16401

MicroMod Main Board - Single | https://www.sparkfun.com/products/18575

MicroMod Environmental Function Board | https://www.sparkfun.com/products/18632

You can also get the sensors individually.

Qwiic SHTC3 | https://www.sparkfun.com/products/16467

Qwiic STC31 | https://www.sparkfun.com/products/18385

Qwiic SGP40 | https://www.sparkfun.com/products/17729

LICENSE: This code is released under the MIT License (http://opensource.org/licenses/MIT)

******************************************************************************/

#include <Wire.h>

#include "SparkFun_SHTC3.h" //Click here to get the library: http://librarymanager/All#SparkFun_SHTC3

SHTC3 mySHTC3; // Create an object of the SHTC3 class

#include "SparkFun_STC3x_Arduino_Library.h" //Click here to get the library: http://librarymanager/All#SparkFun_STC3x

STC3x mySTC3x; // Create an object of the mySTC3x class

#include "SparkFun_SGP40_Arduino_Library.h" // Click here to get the library: http://librarymanager/All#SparkFun_SGP40

SGP40 mySGP40; //Create an object of the SGP40 class

float RH = 0.00; // Variable to keep track of SHTC3 temperature compensation for the STC31

float temperature = 0.00; // Variable to keep track of SHTC3 relative humidity compensation for the STC31

void setup() {

Serial.begin(115200);

//while (!Serial) ; // Wait for Serial Monitor/Plotter to open for Processors with Native USB (i.e. SAMD51)

Serial.println(F("Initializing Combined Example w/ SGP40, SHTC3, and STC31."));

Wire.begin();

//mySTC3x.enableDebugging(); // Uncomment this line to get helpful debug messages on Serial

//mySGP40.enableDebugging(); // Uncomment this line to print useful debug messages to Serial

if (mySHTC3.begin() != SHTC3_Status_Nominal)

{

Serial.println(F("SHTC3 not detected. Please check wiring. Freezing..."));

while (1)

; // Do nothing more

}

if (mySTC3x.begin() == false)

{

Serial.println(F("STC3x not detected. Please check wiring. Freezing..."));

while (1)

; // Do nothing more

}

if (mySGP40.begin() == false)

{

Serial.println(F("SGP40 not detected. Check connections. Freezing..."));

while (1)

; // Do nothing more

}

//We need to tell the STC3x what binary gas and full range we are using

//Possible values are:

// STC3X_BINARY_GAS_CO2_N2_100 : Set binary gas to CO2 in N2. Range: 0 to 100 vol%

// STC3X_BINARY_GAS_CO2_AIR_100 : Set binary gas to CO2 in Air. Range: 0 to 100 vol%

// STC3X_BINARY_GAS_CO2_N2_25 : Set binary gas to CO2 in N2. Range: 0 to 25 vol%

// STC3X_BINARY_GAS_CO2_AIR_25 : Set binary gas to CO2 in Air. Range: 0 to 25 vol%

if (mySTC3x.setBinaryGas(STC3X_BINARY_GAS_CO2_AIR_25) == false)

{

Serial.println(F("Could not set the binary gas! Freezing..."));

while (1)

; // Do nothing more

}

//We can compensate for temperature and relative humidity using the readings from the SHTC3

if (mySHTC3.update() != SHTC3_Status_Nominal) // Request a measurement

{

Serial.println(F("Could not read the RH and T from the SHTC3! Freezing..."));

while (1)

; // Do nothing more

}

//In case the ‘Set temperature command’ has been used prior to the measurement command,

//the temperature value given out by the STC31 will be that one of the ‘Set temperature command’.

//When the ‘Set temperature command’ has not been used, the internal temperature value can be read out.

temperature = mySHTC3.toDegC(); // "toDegC" returns the temperature as a floating point number in deg C

Serial.print(F("Setting STC3x temperature to "));

Serial.print(temperature, 2);

Serial.print(F("C was "));

if (mySTC3x.setTemperature(temperature) == false)

Serial.print(F("not "));

Serial.println(F("successful"));

RH = mySHTC3.toPercent(); // "toPercent" returns the percent humidity as a floating point number

Serial.print(F("Setting STC3x RH to "));

Serial.print(RH, 2);

Serial.print(F("% was "));

if (mySTC3x.setRelativeHumidity(RH) == false)

Serial.print(F("not "));

Serial.println(F("successful"));

//If we have a pressure sensor available, we can compensate for ambient pressure too.

//As an example, let's set the pressure to 840 mbar (== SF Headquarters)

uint16_t pressure = 840;

Serial.print(F("Setting STC3x pressure to "));

Serial.print(pressure);

Serial.print(F("mbar was "));

if (mySTC3x.setPressure(pressure) == false)

Serial.print(F("not "));

Serial.println(F("successful"));

Serial.println(F("Note: Relative humidity and temperature compensation for the STC31 will be updated frequently in the main loop() function."));

} //end setup()

void loop() {

//==============================

//==========READ SHTC3==========

//==============================

//minimum update rate = ~100Hz

SHTC3_Status_TypeDef result = mySHTC3.update(); // Call "update()" to command a measurement, wait for measurement to complete, and update the RH and T members of the object

RH = mySHTC3.toPercent(); // "toPercent" returns the percent humidity as a floating point number

Serial.print(F("RH = "));

Serial.print(RH);

Serial.print(F("%, T = "));

Serial.print(mySHTC3.toDegF()); // "toDegF" return the temperature as a flaoting point number in deg F

Serial.print(F(" deg F, "));

temperature = mySHTC3.toDegC(); // "toDegC" returns the temperature as a floating point number in deg C

Serial.print(temperature);

Serial.print(F(" deg C"));

if (mySHTC3.lastStatus == SHTC3_Status_Nominal) // You can also assess the status of the last command by checking the ".lastStatus" member of the object

{

Serial.println(""); //Sample data good, no need to output a message

}

else {

Serial.print(F(", Update failed, error: ")); //notify user if there is an error

errorDecoder(mySHTC3.lastStatus);

Serial.println("");

}

//==============================

//==========READ STC31==========

//==============================

//minimum update rate = 1Hz

if (mySTC3x.setRelativeHumidity(RH) == false)

Serial.print(F("Unable to set STC31 Relative Humidity with SHTC3."));

if (mySTC3x.setTemperature(temperature) == false)

Serial.println(F("Unable to set STC31 Temperature with SHTC3."));

Serial.print(F("CO2(%): "));

if (mySTC3x.measureGasConcentration()) // measureGasConcentration will return true when fresh data is available

{

Serial.println(mySTC3x.getCO2(), 2);

}

else

{

Serial.print(mySTC3x.getCO2(), 2);

Serial.println(F(", (old STC3 sample reading, STC31 was not able to get fresh data yet)")); //output this note to indicate when we are not able to obtain a new measurement

}

//==============================

//==========READ SGP40==========

//==============================

//minimum update rate = 1Hz

Serial.print(F("VOC Index is: "));

Serial.println(mySGP40.getVOCindex()); //Get the VOC Index using the default RH (50%) and T (25C)

//================================

//=========SPACE & DELAY==========

//================================

//Serial.println("");// Uncomment this line to add some space between readings for the Serial Monitor

delay(1000); //Wait 1 second - the Sensirion VOC and CO2 algorithms expects a sample rate of 1Hz

}//end loop()

void errorDecoder(SHTC3_Status_TypeDef message) // The errorDecoder function prints "SHTC3_Status_TypeDef" results in a human-friendly way

{

switch (message)

{

case SHTC3_Status_Nominal : Serial.print("Nominal"); break;

case SHTC3_Status_Error : Serial.print("Error"); break;

case SHTC3_Status_CRC_Fail : Serial.print("CRC Fail"); break;

default : Serial.print("Unknown return code"); break;

}

}

Example 2: Reading SHTC3, STC31, and SGP40 in CSV

Below is the same combined code but formatted for CSV. If you have not already, select your Board (in this case the MicroMod Artemis), and associated COM port. Copy and paste the code below in your Arduino IDE. Hit the upload button and set the serial monitor to 115200 baud.

language:c

/******************************************************************************

WRITTEN BY: Ho Yun "Bobby" Chan

@ SparkFun Electronics

DATE: 10/19/2021

GITHUB REPO: https://github.com/sparkfun/MicroMod_Environmental_Sensor_Function_Board

DEVELOPMENT ENVIRONMENT SPECIFICS:

Firmware developed using Arduino IDE v1.8.12

========== DESCRIPTION==========

This example code combines example codes from the SHTC3, STC31, and SGP40 libraries.

Most of the steps to obtain the measurements are the same as the example code.

Generic object names were renamed (e.g. mySensor => mySGP40 and mySTC3x).

Example 1: Basic Relative Humidity and Temperature Readings w/ SHTC3; Written by Owen Lyke

Example 2: PHT (SHTC3) Compensated CO2 Readings w/ STC31; Written by Paul Clark and based on earlier code by Nathan Seidle

Example 1: Basic VOC Index w/ SGP40; Written by Paul Clark

Open a Serial Monitor/Plotter at 115200 baud to view the readings!

Note: You may need to wait about ~5 minutes after starting up the code before VOC index

has any values.

========== HARDWARE CONNECTIONS ==========

MicroMod Artemis Processor Board => MicroMod Main Board => MicroMod Environmental Function Board (with SHTC3, STC31, and SGP40)

Feel like supporting open source hardware?

Buy a board from SparkFun!

MicroMod MicroMod Artemis Processor | https://www.sparkfun.com/products/16401

MicroMod Main Board - Single | https://www.sparkfun.com/products/18575

MicroMod Environmental Function Board | https://www.sparkfun.com/products/18632

You can also get the sensors individually.

SHTC3 | https://www.sparkfun.com/products/16467

STC31 | https://www.sparkfun.com/products/18385

SGP40 | https://www.sparkfun.com/products/17729

LICENSE: This code is released under the MIT License (http://opensource.org/licenses/MIT)

******************************************************************************/

#include <Wire.h>

#include "SparkFun_SHTC3.h" //Click here to get the library: http://librarymanager/All#SparkFun_SHTC3

SHTC3 mySHTC3; // Create an object of the SHTC3 class

#include "SparkFun_STC3x_Arduino_Library.h" //Click here to get the library: http://librarymanager/All#SparkFun_STC3x

STC3x mySTC3x; // Create an object of the STC3x class

#include "SparkFun_SGP40_Arduino_Library.h" // Click here to get the library: http://librarymanager/All#SparkFun_SGP40

SGP40 mySGP40; //Create an object of the SGP40 class

float RH = 0.00; // Variable to keep track of SHTC3 temperature compensation for the STC31

float temperature = 0.00; // Variable to keep track of SHTC3 relative humidity compensation for the STC31

//Debug mode, comment one of these lines out using a syntax

//for a single line comment ("//"):

#define DEBUG 0 //0 = Output for Serial Plotter, CSV

//#define DEBUG 1 //1 = Output for Serial Monitor

void setup() {

Serial.begin(115200);

//while (!Serial) ; // Wait for Serial Monitor/Plotter to open for Processors with Native USB (i.e. SAMD51)

#if DEBUG

Serial.println(F("Initializing Combined Example w/ SGP40, SHTC3, and STC31."));

#else

Serial.println(F("RH,degF,degC,SHTC3_Valid,RH_Compensate_Valid,degC_Compensate_Valid,CO2%,STC31_Valid,VOC_Index"));

#endif

Wire.begin();

//mySTC3x.enableDebugging(); // Uncomment this line to get helpful debug messages on Serial

//mySGP40.enableDebugging(); // Uncomment this line to print useful debug messages to Serial

if (mySHTC3.begin() != SHTC3_Status_Nominal)

{

#if DEBUG

Serial.println(F("SHTC3 not detected. Please check wiring. Freezing..."));

#endif

while (1)

; // Do nothing more

}

if (mySTC3x.begin() == false)

{

#if DEBUG

Serial.println(F("STC3x not detected. Please check wiring. Freezing..."));

#endif

while (1)

; // Do nothing more

}

if (mySGP40.begin() == false)

{

#if DEBUG

Serial.println(F("SGP40 not detected. Check connections. Freezing..."));

#endif

while (1)

; // Do nothing more

}

//We need to tell the STC3x what binary gas and full range we are using

//Possible values are:

// STC3X_BINARY_GAS_CO2_N2_100 : Set binary gas to CO2 in N2. Range: 0 to 100 vol%

// STC3X_BINARY_GAS_CO2_AIR_100 : Set binary gas to CO2 in Air. Range: 0 to 100 vol%

// STC3X_BINARY_GAS_CO2_N2_25 : Set binary gas to CO2 in N2. Range: 0 to 25 vol%

// STC3X_BINARY_GAS_CO2_AIR_25 : Set binary gas to CO2 in Air. Range: 0 to 25 vol%

if (mySTC3x.setBinaryGas(STC3X_BINARY_GAS_CO2_AIR_25) == false)

{

#if DEBUG

Serial.println(F("Could not set the binary gas! Freezing..."));

#endif

while (1)

; // Do nothing more

}

//We can compensate for temperature and relative humidity using the readings from the SHTC3

if (mySHTC3.update() != SHTC3_Status_Nominal) // Request a measurement

{

#if DEBUG

Serial.println(F("Could not read the RH and T from the SHTC3! Freezing..."));

#endif

while (1)

; // Do nothing more

}

//In case the ‘Set temperature command’ has been used prior to the measurement command,

//the temperature value given out by the STC31 will be that one of the ‘Set temperature command’.

//When the ‘Set temperature command’ has not been used, the internal temperature value can be read out.

temperature = mySHTC3.toDegC(); // "toDegC" returns the temperature as a floating point number in deg C

#if DEBUG

Serial.print(F("Setting STC3x temperature to "));

Serial.print(temperature, 2);

Serial.print(",");

Serial.print(F("C was "));

#endif

if (mySTC3x.setTemperature(temperature) == false) {

#if DEBUG

Serial.print(F("not "));

#endif

}

#if DEBUG

Serial.println(F("successful"));

#endif

RH = mySHTC3.toPercent(); // "toPercent" returns the percent humidity as a floating point number

#if DEBUG

Serial.print(F("Setting STC3x RH to "));

Serial.print(RH, 2);

Serial.print(",");

Serial.print(F("% was "));

#endif

if (mySTC3x.setRelativeHumidity(RH) == false) {

#if DEBUG

Serial.print(F("not "));

#endif

}

#if DEBUG

Serial.println(F("successful"));

#endif

//If we have a pressure sensor available, we can compensate for ambient pressure too.

//As an example, let's set the pressure to 840 mbar (== SF Headquarters)

uint16_t pressure = 840;

#if DEBUG

Serial.print(F("Setting STC3x pressure to "));

Serial.print(pressure);

Serial.print(F("mbar was "));

#endif

if (mySTC3x.setPressure(pressure) == false) {

#if DEBUG

Serial.print(F("not "));

#endif

}

#if DEBUG

Serial.println(F("successful"));

Serial.println(F("Note: Relative humidity and temperature compensation for the STC31 will be updated frequently in the main loop() function."));

#endif

} //end setup()

void loop() {

//==============================

//======DEBUG TURNED ON=========

//==============================

#if DEBUG

//==============================

//==========READ SHTC3==========

//==============================

//minimum update rate = ~100Hz

SHTC3_Status_TypeDef result = mySHTC3.update(); // Call "update()" to command a measurement, wait for measurement to complete, and update the RH and T members of the object

RH = mySHTC3.toPercent(); // "toPercent" returns the percent humidity as a floating point number

Serial.print(F("RH = "));

Serial.print(RH);

Serial.print(F("%, T = "));

Serial.print(mySHTC3.toDegF()); // "toDegF" return the temperature as a flaoting point number in deg F

Serial.print(F(" deg F, "));

temperature = mySHTC3.toDegC(); // "toDegC" returns the temperature as a floating point number in deg C

Serial.print(temperature);

Serial.print(F(" deg C"));

if (mySHTC3.lastStatus == SHTC3_Status_Nominal) // You can also assess the status of the last command by checking the ".lastStatus" member of the object

{

Serial.println(""); //Sample data good, no need to output a message

}

else {

Serial.print(F(", Update failed, error: ")); //notify user if there is an error

errorDecoder(mySHTC3.lastStatus);

Serial.println("");

}

//==============================

//==========READ STC31==========

//==============================

//minimum update rate = 1Hz

if (mySTC3x.setRelativeHumidity(RH) == false)

Serial.print(F("Unable to set STC31 Relative Humidity with SHTC3."));

if (mySTC3x.setTemperature(temperature) == false)

Serial.println(F("Unable to set STC31 Temperature with SHTC3."));

Serial.print(F("CO2(%): "));

if (mySTC3x.measureGasConcentration()) // measureGasConcentration will return true when fresh data is available

{

Serial.println(mySTC3x.getCO2(), 2);

}

else

{

Serial.print(mySTC3x.getCO2(), 2);

Serial.println(F(", (old STC3 sample reading, STC31 was not able to get fresh data yet)")); //output this note to indicate when we are not able to obtain a new measurement

}

//==============================

//==========READ SGP40==========

//==============================

//minimum update rate = 1Hz

Serial.print(F("VOC Index is: "));

Serial.println(mySGP40.getVOCindex()); //Get the VOC Index using the default RH (50%) and T (25C)

//==============================

//=====DEBUG TURNED OFF=========

//==============================

#else

//==============================

//==========READ SHTC3==========

//==============================

//minimum update rate = ~100Hz

SHTC3_Status_TypeDef result = mySHTC3.update(); // Call "update()" to command a measurement, wait for measurement to complete, and update the RH and T members of the object

RH = mySHTC3.toPercent();

Serial.print(RH);

Serial.print(",");

Serial.print(mySHTC3.toDegF());

Serial.print(",");

temperature = mySHTC3.toDegC(); // "toDegC" returns the temperature as a floating point number in deg C

Serial.print(temperature);

Serial.print(",");

if (mySHTC3.lastStatus == SHTC3_Status_Nominal) // You can also assess the status of the last command by checking the ".lastStatus" member of the object

{

Serial.print("1"); //Sample data good, no need to output a message

Serial.print(",");

}

else

{

Serial.print("0"); //Sample data bad, no need to output a message

Serial.print(",");

}

//==============================

//==========READ STC31==========

//==============================

//minimum update rate = 1Hz

if (mySTC3x.setRelativeHumidity(RH) == false)

{

//Serial.print(F("Unable to set STC31 Relative Humidity with SHTC3."));

Serial.print("0");

Serial.print(",");

}

else

{

Serial.print("1");

Serial.print(",");

}

if (mySTC3x.setTemperature(temperature) == false)

{

//Serial.println(F("Unable to set STC31 Temperature with SHTC3."));

Serial.print("0");

Serial.print(",");

}

else

{

Serial.print("1");

Serial.print(",");

}

if (mySTC3x.measureGasConcentration()) // measureGasConcentration will return true when fresh data is available

{

Serial.print(mySTC3x.getCO2(), 2);

Serial.print(",");

Serial.print("1"); //Fresh Data

Serial.print(",");

}

else

{

Serial.print(mySTC3x.getCO2(), 2);

Serial.print(",");

Serial.print("0"); //Data not fresh

Serial.print(",");

}

//==============================

//==========READ SGP40==========

//==============================

//minimum update rate = 1Hz

Serial.println(mySGP40.getVOCindex()); //Get the VOC Index using the default RH (50%) and T (25C)

#endif

//================================

//=========SPACE & DELAY==========

//================================

//Serial.println("");// Uncomment this line to add some space between readings for the Serial Monitor

delay(1000); //Wait 1 second - the Sensirion VOC algorithm expects a sample rate of 1Hz

}//end loop()

void errorDecoder(SHTC3_Status_TypeDef message) // The errorDecoder function prints "SHTC3_Status_TypeDef" resultsin a human-friendly way

{

switch (message)

{

case SHTC3_Status_Nominal : Serial.print("Nominal"); break;

case SHTC3_Status_Error : Serial.print("Error"); break;

case SHTC3_Status_CRC_Fail : Serial.print("CRC Fail"); break;

default : Serial.print("Unknown return code"); break;

}

}

Troubleshooting

If you need technical assistance and more information on a product that is not working as you expected, we recommend heading on over to the SparkFun Technical Assistance page for some initial troubleshooting.

If you don't find what you need there, the SparkFun Forums: MicroMod are a great place to find and ask for help. If this is your first visit, you'll need to create a Forum Account to search product forums and post questions.

Resources and Going Further

Now that you've successfully got your MicroMod Environmental Function Board up and running, it's time to incorporate it into your own project! For more information, check out the resources below:

- Schematic (PDF)

- Eagle Files (ZIP)

- Board Dimensions (PNG)

- SGP40

- SHTC3

- STC31

- Arduino Libraries

- GitHub Hardware Repo

- SFE Product Showcase

Need some inspiration for your next project? Check out some of these related tutorials with MicroMod:

Getting Started with MicroMod

MicroMod SAMD51 Processor Board Hookup Guide

MicroMod ESP32 Processor Board Hookup Guide

MicroMod Teensy Processor Hookup Guide

learn.sparkfun.com | CC BY-SA 3.0 | SparkFun Electronics | Niwot, Colorado

](http://cdn.sparkfun.com/assets/learn_tutorials/1/8/5/7/SparkFun_RTK_Express_-_Logging_Menu.jpg)

A label maker is a non-permanent solution to putting the MAC address on each board.

A label maker is a non-permanent solution to putting the MAC address on each board.