Nuclear Battery Assembly Guide a learn.sparkfun.com tutorial

Available online at: http://sfe.io/t788

A Healthy Green Glow

After we caught sight of some very cool folks online making their very own homemade nuclear batteries, we knew we had to give it a go!

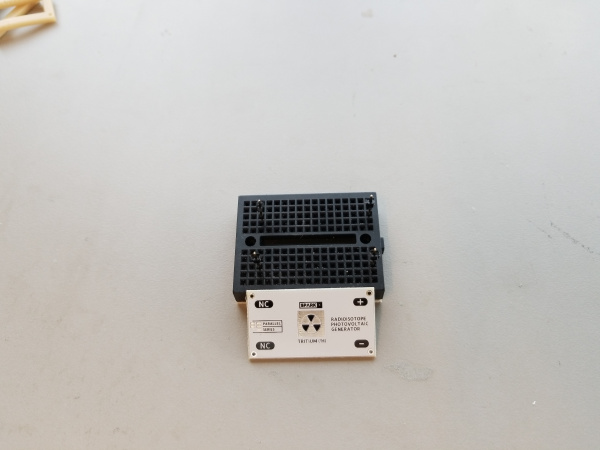

These devices are actually known as “Radioisotope Photovoltaic Generators” or “Photobetavoltaic Generators,” and they’re a pretty clever design: Glowing glass pills filled with Tritium gas and coated in a phosphorescent material are sandwiched between two photovoltaic cells. The beta radiation emitted by the Tritium is blocked by the glass walls of the pill, but they cause the phosphorescent coating to glow. This light has no trouble passing through the glass and lands on the photovoltaic cells where it produces a small amount of electricity!

Image courtesy of citylabs.net

Commercial Tritium batteries — like those produced by City Labs— cut out the middleman by using betavoltaic (as opposed to photovoltaic) cells in direct contact with Tritium gas. Those commercial devices are more rugged and efficient, but come with a very large price tag (thousands of USD per unit).

Image courtesy of NurdRage

On the other hand, homemade devices constructed using the packing tape sandwich method are as cheap as it gets, but aren’t particularly rugged.

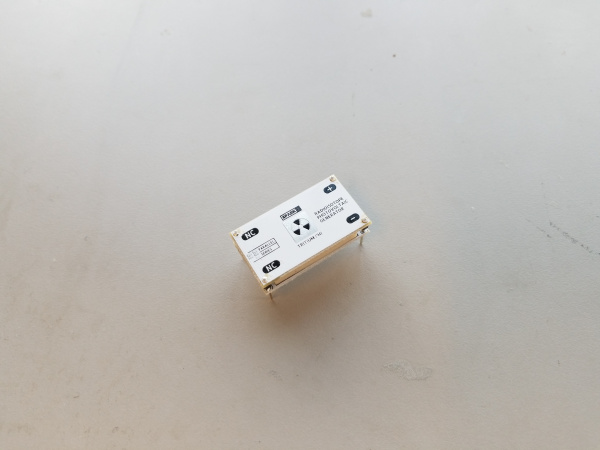

This kit provides a good compromise between price and quality of construction. We’ve designed carrier boards for both of the photovoltaic cells which we supply pre-soldered and fixed to the boards with chipbonder. We’ve also designed and cast custom silicone rubber grommets which cushion the Tritium vials between the two photovoltaic cells, preventing the cells from getting scratched or chipped and — most importantly — the vials from getting broken. The carrier boards also allow you to choose whether the photovoltaic cells are wired in series or parallel and provide you with breadboard compatible pin spacing for the battery terminals.

A Brief Word on Tritium Gas Lights

Before you get started, you’ll need to get your hands on some 2x12mm Tritium glow vials, 10 of them. These are sold under various tradenames such as:

- Mixglo

- DaxLight

- BETALight

- Gaseous Tritium Light Source (GTLS)

- Tritium Glow Tube

- Tritium Gas Tube

- Tritium Glow Vial

They’re easily found on sites such as ebay, banggood, aliexpress, etc. as well as certain specialty websites. Although their sale is regulated in many countries — and you should be aware of your local laws before attempting to procure any radioisotope — we didn’t have any trouble mail-ordering a small number of them in the US.

These Tritium Glow Tubes are perfectly safe to handle as the beta radiation generated from the Tritium decay cannot pass through the glass wall of the vial. Incidentally, the collision of the beta particles with the glass does produce a very tiny amount of x-rays, but not enough to harm anything. The only danger associated with Tritium gas is if it is inhaled, injected or otherwise inserted into the body which can only happen if you break the glass vial. If a vial does break, evacuate the room for a while to allow the gas to dissipate. Tritium occurs naturally in very small quantities and has a very short half-life compared with other glow products (such as radium) so breaking a glow vial will not turn your home into a superfund site.

If you’d like to learn more about Tritium Glow Tubes, you can check out this excellent blog post on how they’re made and how they’re used in watchmaking!

Some Assembly Required

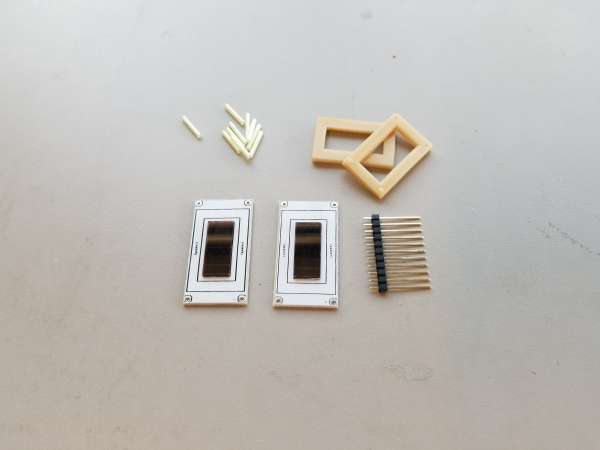

Step 1 - Gather Materials

Grab your 2x12mm Tritium Gas Tubes, the contents of the Nuclear Battery Kit, some soldering supplies, and a breadboard (if you have one). It’s not a bad idea to polish the PV cells with a soft cloth and maybe your tritium vials as well just to remove any smudges or dust that could effect the efficiency of the PV cells.

Step 2 - Attach Headers to the Top PCB

Your kit came with a strip of breakaway headers. You really just need four of them, but they sometimes get bent or don’t break off cleanly so we tossed in a bunch just to be safe. Use a pair of pliers or wire snips to break off four individual pins.

This next part is easier if you have a breadboard to hold the pins in place while you work, but you can manage without one. In the picture below, I’ve stuck the pin headers into my breadboard long-side-down in preparation to solder them to my top PCB. You can tell which one is the top because it will have the SparkX logo as well as some solder jumpers on the side opposite the PV cell.

Now simply solder each pin into place with a generous solder joint.

You can remove your soldered assembly and flip it upside-down in preparation for the next step:

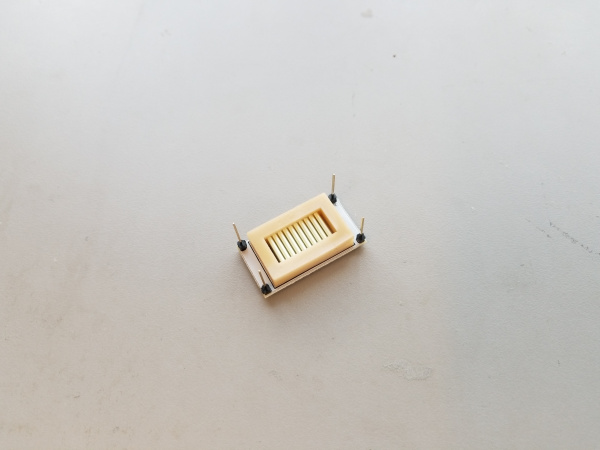

Step 3 - Make the Stack

Now you need to grab one of the silicone rubber gaskets. It doesn’t matter which one because they’re identical. Place it with the flat side down and the pips facing up in the area marked “gasket” on the PCB.

This step can be a little finicky, but take your time and use tweezers if you need to. Place each of the 10 Tritium gas tubes into the rubber gasket. It helps to start at one end and move across. Place one end of each tube gently into a ridge on one side of the gasket and then gently press down until the other side slides into its corresponding ridge.

After all of the tubes are in place, you can press on them gently with a flat object to make sure they’re seated. They should look like this:

Now cap the tubes with the other rubber gasket, being sure to align the holes and pips so that they mate together.

Finally, you can slide the bottom PCB onto the stack. Careful! Make sure that the board is oriented correctly. The “NC,” “+,” and “-” pin labels on both boards should line up!

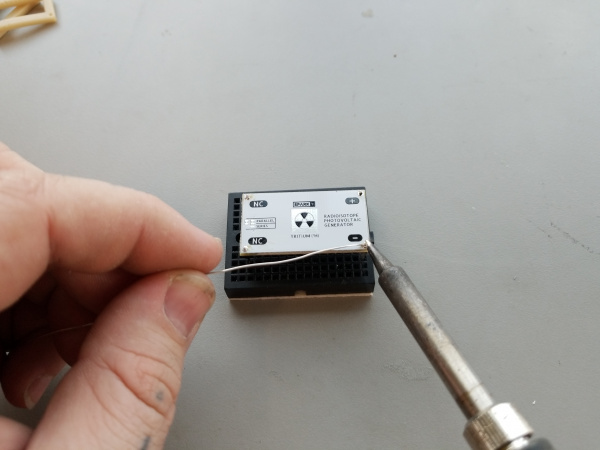

Step 4 - Solder It All Together

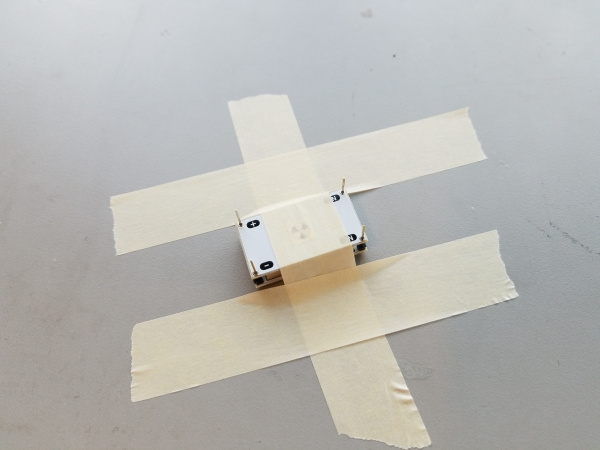

For this step, you’ll want to apply some clamping force to the stack. Too much force will deform the rubber gaskets, causing the tubes to rattle loose in the assembly and you’ll need to re-build your stack. A small weight or a very weak binder clip should work, but I find masking tape is also acceptable.

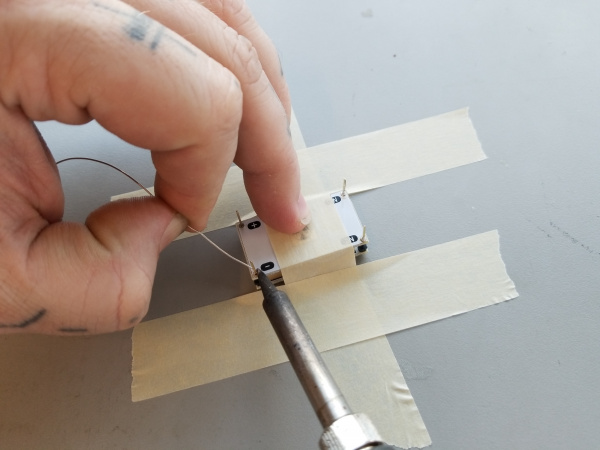

Now solder each of the four pins, these provide both the electrical connection between the PV cells and the mechanical connection which holds the generator together. Do not clip the headers after soldering as they will act as the leads for your battery.

Once you’re finished soldering, your battery is complete!

A Little Bit of Power

So how much power does it make? Not much. The best measurement we were able to make (using the method outlined by NurdRage) suggests that the maximum power point of this arrangement is 25nW, if you can build a circuit that loads it properly (between 20 and 30nA at about 0.6v). Further experiments show that the battery will — given enough time — charge a capacitor to a voltage of 1.5 volts. Using this battery to do any work will likely involve a clever energy harvesting circuit, but keep in mind that this tiny amount of power will continue to flow for about 20 years — the half life of Tritium being 12 years.

learn.sparkfun.com | CC BY-SA 3.0 | SparkFun Electronics | Niwot, Colorado