Introduction: SIK RedBoard & Starter Kit

The SparkFun Inventor’s Guide is your map for navigating the waters of beginning embedded electronics. This guide contains all the information you will need to explore the 16 circuits of the SparkFun Inventor’s Kit for Arduino V3.2. At the center of this guide is one core philosophy - that anyone can (and should) play around with electronics. When you’re done with this guide, you’ll have the know-how to start creating your own projects and experiments. Now enough talking - let’s get inventing!

For Starter Kit for RedBoard - Programmed with Arduino users: For those who have Starter Kit for RedBoard - Programmed with Arduino, you are able to follow through experiments 1, 2, 3, 6, 7, 9, 10, and 11.

SparkFun Inventor’s Kit - V3.2

![alt text]()

Here is all the parts in the SparkFun Inventor’s Kit for Arduino:

- SparkFun RedBoard - Programmed with Arduino - The SparkFun RedBoard, fully assembled and tested

- Arduino and Breadboard Holder - A nice holder for your RedBoard and breadboard

- SparkFun Inventor’s Kit Guidebook - A printed manual that you follow along through all the experiments

- Breadboard - Excellent for making circuits and connections off the Arduino.

- Carrying Case - Take your kit anywhere with ease

- SparkFun Mini Screwdriver - To help you screw on your RedBoard to the holder

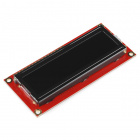

- 16x2 White on Black LCD (with headers) - This is a basic 16 character by 2 line display with a snazzy black background with white characters.

- 74HC595 Shift Register- Simple shift register IC. Clock in data and latch it to free up IO pins on your RedBoard.

- 2N2222 Transistors - This little transistor can help in your project by being used to help drive large loads or amplifying or switching applications.

- 1N4148 Diodes - This is a very common signal diode - 1N4148. Use this for signals up to 200mA of current.

- DC Motor with Gear - It works well for basic things like making a fan or spinning something pretty fast without much resistance.

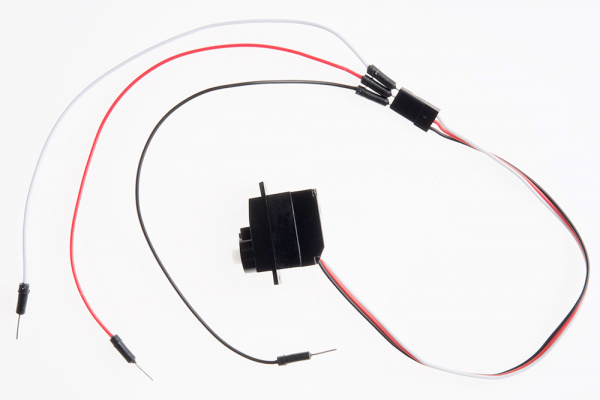

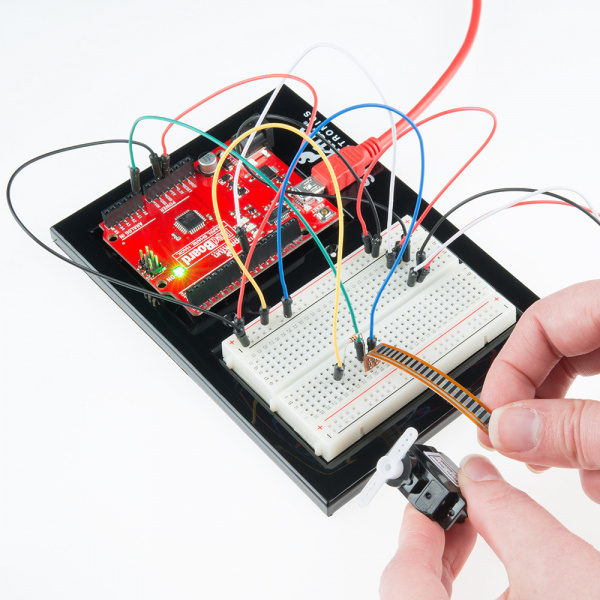

- Small Servo - Here is a simple, low-cost, high quality servo for all your mechatronic needs.

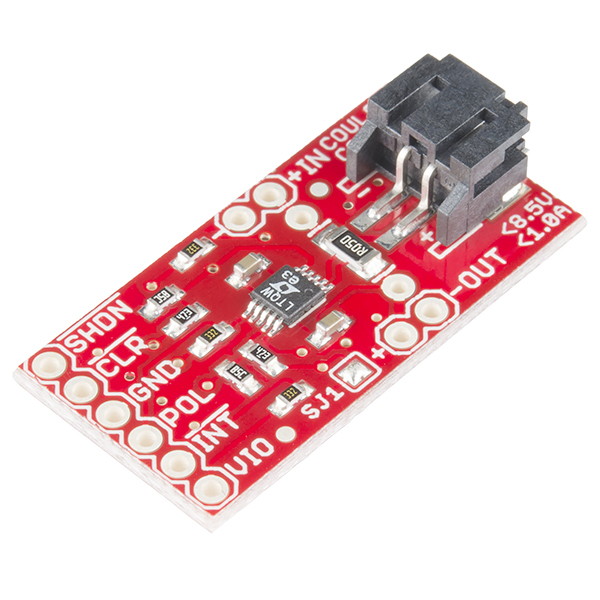

- SPDT 5V Relay - This is a high quality Single Pole - Double Throw (SPDT) sealed relay. Use it to switch high voltage, and/or high current devices. This relay’s coil is rated up to 12V, with a minimum switching voltage of 5V.

- TMP36 Temp Sensor - A sensor for detecting temperature changes.

- Flex sensor - As the sensor is flexed, the resistance across the sensor increases.

- Softpot - By pressing down on various parts of the strip, the resistance linearly changes from 100Ohms to 10,000Ohms allowing you to very accurately calculate the relative position on the strip.

- SparkFun USB Mini-B Cable - This 6' cable provides you with a USB-A connector at the host end and mini-B connector at the device end.

- Male to Male jumper wires - These are high quality wires that allow you to connect the female headers on the Arduino to the components and breadboard.

- Photocell - A sensor to detect ambient light. Perfect for detecting when a drawer is opened or when night-time approaches.

- Tri-Color LED - Because everyone loves a blinky.

- Red, Blue, Yellow, and Green LEDs - Light emitting diodes make great general indicators.

- Red, Blue, Yellow, and Green Tactile Buttons - Go crazy with different colored buttons

- 10K Trimpot - Also known as a variable resistor, this is a device commonly used to control volume, contrast, and makes a great general user control input.

- Piezo Buzzer - Use this to make sounds and play songs

- 330 Ohm Resistors - Great current limiting resistors for LEDs, and strong pull-up resistors.

- 10k Ohm Resistors - These make excellent pull-ups, pull-downs, and current limiters.

Starter Kit for RedBoard - Programmed with Arduino

If you’re new to electronics and programming, the Starter Kit for RedBoard is a great way for beginners to get their foot in the door. This little guy is essentially a mini SparkFun Inventor’s Kit (minus the manual which you can find below) and can be taken straight out of the box to help you make a slew of basic circuits.

Here is all the parts in the Starter Kit for RedBoard - V2:

Please note: This product is in the works, however you are able to follow along if you already have the Starter Kit for RedBoard for a lot of the experiments.

- RedBoard - Programmed with Arduino - The SparkFun RedBoard, fully assembled and tested.

- SparkFun USB Mini-B Cable - This 6' cable provides you with a USB-A connector at the host end and mini-B connector at the device end.

- Breadboard - Excellent for making circuits and connections off the Arduino.

- Male to Male jumper wires - These are high quality wires that allow you to connect the female headers on the Arduino to the components and breadboard.

- Photocell - A sensor to detect ambient light. Perfect for detecting when a drawer is opened or when night-time approaches.

- TMP36 Temp Sensor - A sensor for detecting temperature changes.

- Tri-Color LED - Because everyone loves a blinky. Use this LED to PWM mix any color you need.

- Basic LEDs - Light emitting diodes make great general indicators.

- 10K Trimpot - Also known as a variable resistor, this is a device commonly used to control volume, contrast, and makes a great general user control input.

- 12mm button - Because big buttons are easier to hit.

- Small Servo - Here is a simple, low-cost, high quality servo for all your mechatronic needs.

- 330 Ohm Resistors - Great current limiting resistors for LEDs, and strong pull-up resistors.

- 10k Ohm Resistors - These make excellent pull-ups, pull-downs, and current limiters.

Experiment List

Please note: Experiments marked with **double asterisks** are for both the Starter Kit for RedBoard - Programmed with Arduino V2 (which is a future release) and the RedBoard SIK V3.2. Experiments without asterisks will only be available to those who purchased the RedBoard SIK V3.2.

In this SparkFun Inventor’s Kit for Arduino guide, you will learn the following:

What is the RedBoard platform?

The DIY Revolution

We live in a unique time where we have access to resources that allow us to create our own solutions and inventions. The DIY revolution is composed of hobbyists, tinkerers and inventors who would rather craft their own projects than let someone do it for them.

A Computer for the Physical World

The RedBoard in your hand (or on your desk) is your development platform. At its roots, the RedBoard is essentially a small portable computer. It is capable of taking inputs (such as the push of a button or a reading from a light sensor) and interpreting that information to control various outputs (like a blinking LED light or an electric motor).

That’s where the term “physical computing” is born - this board is capable of taking the world of electronics and relating it to the physical world in a real and tangible way. Trust us - this will all make more sense soon.

The SparkFun RedBoard is one of a multitude of development boards based on the ATmega328. It has 14 digital input/output pins (6 of which can be PWM outputs), 6 analog inputs, a 16 MHz crystal oscillator, a USB connection, a power jack, an ISP header, and a reset button. Check out our RedBoard Hookup Guide, to get yourself familiar with the RedBoard.

Download the Arduino IDE

In order to get your RedBoard up and running, you’ll need to download the newest version of the Arduino software first from www.arduino.cc (it’s free and open source!). This software, known as the Arduino IDE, will allow you to program the board to do exactly what you want. It’s like a word processor for writing programs. With an internet-capable computer, open up your favorite browser and go to Arduino download page.

Check out our Installing Arduino IDE tutorial, to see in detail on how to install the Arduino IDE on your computer.

Connect your RedBoard to your Computer

Use the USB cable provided in the SIK kit to connect the RedBoard to one of your computer’s USB inputs.

Install FTDI Drivers

Depending on your computer’s operating system, you will need to follow specific instructions. Please go to How to Install FTDI Drivers, for specific instructions on how to install the FTDI drivers onto your RedBoard.

Getting Started in the Arduino IDE

Now, it’s finally time to open up the Arduino software. You’ll be presented with a window that looks a little something like this:

![Arduino IDE annotated]()

- Verify: Compiles and approves your code. It will catch errors in syntax (like missing semi-colons or parenthesis).

- Upload: Sends your code to the RedBoard. When you click it, you should see the lights on your board blink rapidly.

- New: This buttons opens up a new code window tab.

- Open: This button will let you open up an existing sketch.

- Save: This saves the currently active sketch.

- Serial Monitor: This will open a window that displays any serial information your RedBoard is transmitting. It is very useful for debugging.

- Sketch Name: This shows the name of the sketch you are currently working on.

- Code Area: This is the area where you compose the code for your sketch.

- Message Area: This is where the IDE tells you if there were any errors in your code.

- Text Console: The text console shows complete error messages. When debugging, the text console is very useful.

- Board and Serial Port: Shows you what board and the serial port selections

Select your board: Arduino Uno

Before we can start jumping into the experiments, there are a couple adjustments we need to make.

This step is required to tell the Arduino IDE which of the many Arduino boards we have. Go up to the Tools menu. Then hover over Board and make sure Arduino Uno is selected.

Please note: Your SparkFun RedBoard and the Arduino UNO are interchangeable but you won’t find the RedBoard listed in the Arduino Software. Select “Arduino Uno” instead.

![Arduino Select Arduino Uno board]()

Select a Serial Port

Next up we need to tell the Arduino IDE which of our computer’s serial ports the RedBoard is connected to. For this, again go up to Tools, then hover over Serial Port and select your RedBoard’s serial port.

Window Users: This is likely to be com3 or higher (COM1 and COM2 are usually reserved for hardware serial ports). To find out, you can disconnect your RedBoard and re-open the menu; the entry that disappears should be the RedBoard. Reconnect the board and select that serial port.

![Port Selection]()

Mac Users: Select the serial device of the RedBoard from the Tools, then hover over Serial Port. On the Mac, this should be something with /dev/tty.usbmodem or /dev/tty.usbserial in it.

![Mac user Arduino Serial Port]()

Linux Users: Please visit the Arduino Learning Linux section, to learn more about Arduino on Linux.

Download Arduino Code

You are so close to to being done with setup! Download the SIK Guide Code. Click the following link to download the code:

Copy “SIK Guide Code” into “examples” folder in the Arduino folder.

Window Users: Unzip the file “SIK Guide Code”. It should be located in your browser’s “Downloads” folder. Right click the zipped folder and choose “unzip”. Copy the “SIK Guide Code” folder into Arduino’s folder named “examples”.

Mac Users: Unzip the file “SIK Guide Code”. It should be located in your browser’s “Downloads” folder. Right click the zipped folder and choose “unzip”. Find “Arduino” in your applications folder. Right click (ctrl + click) on “Arduino”. Select “Show Package Contents”. Then, click through folders Contents > Resources > Java > examples. Copy the “SIK Guide Code” folder into Arduino’s folder named “examples”.

Suggested Reading

Before continuing on with this tutorial, we recommend you be somewhat familiar with the concepts in the following tutorial:

- How to Use a Breadboard - First time working with a breadboard? Please check out this tutorial! It will help you understand why the breadboard is a great for prototyping and how to use one.

Time for the fun part!

Continue on to the first experiment and in no time you will be blinking an LED!

Introduction: SIK Arduino Uno

The SparkFun Inventor’s Guide is your map for navigating the waters of beginning embedded electronics. This guide contains all the information you will need to explore the 16 circuits of the SparkFun Inventor’s Kit for Arduino. At the center of this guide is one core philosophy - that anyone can (and should) play around with electronics. When you’re done with this guide, you’ll have the know-how to start creating your own projects and experiments. Now enough talking - let’s get inventing!

![alt text]()

SparkFun Inventor’s Kit with Arduino Uno R3

Here is all the parts in the SparkFun Inventor’s Kit for Arduino:

- Arduino Uno R3 - The Arduino Uno is one of the more popular boards in the Arduino family and a great choice for beginners.

- Arduino and Breadboard Holder - A nice holder for your RedBoard and breadboard

- SparkFun Inventor’s Kit Guidebook - A printed manual that you follow along through all the experiments

- Breadboard - Excellent for making circuits and connections off the Arduino.

- Carrying Case - Take your kit anywhere with ease

- SparkFun Mini Screwdriver - To help you screw on your RedBoard to the holder

- 16x2 White on Black LCD (with headers) - This is a basic 16 character by 2 line display with a snazzy black background with white characters.

- 74HC595 Shift Register- Simple shift register IC. Clock in data and latch it to free up IO pins on your RedBoard.

- 2N2222 Transistors - This little transistor can help in your project by being used to help drive large loads or amplifying or switching applications.

- 1N4148 Diodes - This is a very common signal diode - 1N4148. Use this for signals up to 200mA of current.

- DC Motor with Gear - It works well for basic things like making a fan or spinning something pretty fast without much resistance.

- Small Servo - Here is a simple, low-cost, high quality servo for all your mechatronic needs.

- SPDT 5V Relay - This is a high quality Single Pole - Double Throw (SPDT) sealed relay. Use it to switch high voltage, and/or high current devices. This relay’s coil is rated up to 12V, with a minimum switching voltage of 5V.

- TMP36 Temp Sensor - A sensor for detecting temperature changes.

- Flex sensor - As the sensor is flexed, the resistance across the sensor increases

- Softpot - By pressing down on various parts of the strip, the resistance linearly changes from 100Ohms to 10,000Ohms allowing you to very accurately calculate the relative position on the strip.

- SparkFun USB Mini-B Cable - This 6' cable provides you with a USB-A connector at the host end and mini-B connector at the device end.

- Male to Male jumper wires - These are high quality wires that allow you to connect the female headers on the Arduino to the components and breadboard.

- Photocell - A sensor to detect ambient light. Perfect for detecting when a drawer is opened or when night-time approaches.

- Tri-Color LED - Because everyone loves a blinky.

- Red, Blue, Yellow, and Green LEDs - Light emitting diodes make great general indicators.

- Red, Blue, Yellow, and Green Tactile Buttons - Go crazy with different colored buttons

- 10K Trimpot - Also known as a variable resistor, this is a device commonly used to control volume, contrast, and makes a great general user control input.

- Piezo Buzzer - Use this to make sounds and songs

- 330 Ohm Resistors - Great current limiting resistors for LEDs, and strong pull-up resistors.

- 10k Ohm Resistors - These make excellent pull-ups, pull-downs, and current limiters.

Experiment List

In this SparkFun Inventor’s Kit for Arduino guide, you will learn the following:

Please note: Got the Starter Kit for RedBoard - Programmed with Arduino? The experiments with the double asterisks you will want to follow along too.

What is the Arduino platform?

The DIY Revolution

We live in a unique time where we have access to resources that allow us to create our own solutions and inventions. The DIY revolution is composed of hobbyists, tinkerers and inventors who would rather craft their own projects than let someone do it for them.

A Computer for the Physical World

The Arduino in your hand (or on your desk) is your development platform. It is capable of taking inputs (such as the push of a button or a reading from a light sensor) and interpreting that information to control various outputs (like a blinking LED light or an electric motor).

That’s where the term “physical computing” is born - this board is capable of taking the world of electronics and relating it to the physical world in a real and tangible way. Trust us - this will all make more sense soon.

The Uno is a great choice for your first Arduino. It’s got everything you need to get started, and nothing you don’t. It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a USB connection, a power jack, a reset button and more. It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started. Check out our What is an Arduino? tutorial, to learn more about Arduino.

Connect your Arduino Uno R3 to your Computer

Use the USB cable provided in the SIK kit to connect the Arduino Uno to one of your computer’s USB inputs.

Download the Arduino IDE

In order to get your Arduino Uno R3 up and running, you’ll need to download the newest version of the Arduino software first from www.arduino.cc (it’s free and open source!). This software, known as the Arduino IDE, will allow you to program the board to do exactly what you want. It’s like a word processor for writing programs. With an internet-capable computer, open up your favorite browser and go to Arduino download page.

Check out our Installing Arduino IDE tutorial, to see in detail on how to install the Arduino IDE on your computer.

Getting Started in the Arduino IDE

Now, it’s finally time to open up the Arduino software. You’ll be presented with a window that looks a little something like this:

![Arduino IDE annotated]()

- Verify: Compiles and approves your code. It will catch errors in syntax (like missing semi-colons or parenthesis).

- Upload: Sends your code to the RedBoard. When you click it, you should see the lights on your board blink rapidly.

- New: This buttons opens up a new code window tab.

- Open: This button will let you open up an existing sketch.

- Save: This saves the currently active sketch.

- Serial Monitor: This will open a window that displays any serial information your RedBoard is transmitting. It is very useful for debugging.

- Sketch Name: This shows the name of the sketch you are currently working on.

- Code Area: This is the area where you compose the code for your sketch.

- Message Area: This is where the IDE tells you if there were any errors in your code.

- Text Console: The text console shows complete error messages. When debugging, the text console is very useful.

- Board and Serial Port: Shows you what board and the serial port selections

Before we can start jumping into the experiments, there are a couple adjustments we need to make.

Select your board: Arduino Uno

This step is required to tell the Arduino IDE which of the many Arduino boards we have. Go up to the Tools menu. Then hover over Board and make sure Arduino Uno is selected.

![Arduino Select Arduino Uno board]()

Select a Serial Port

Next up we need to tell the Arduino IDE which of our computer’s serial ports the Arduino Uno R3 is connected to. For this, again go up to Tools, then hover over Serial Port and select your Arduino Uno R3’s serial port.

![Port Selection]()

Window Users: This is likely to be com3 or higher (COM1 and COM2 are usually reserved for hardware serial ports). To find out, you can disconnect your Arduino Uno R3 and re-open the menu; the entry that disappears should be the Arduino Uno R3. Reconnect the board and select that serial port.

Mac Users: Select the serial device of the Arduino Uno R3 from the Tools, then hover over Serial Port. On the Mac, this should be something with /dev/tty.usbmodem or /dev/tty.usbserial in it.

Linux Users: Please visit the Arduino Learning Linux section, to learn more about Arduino on Linux.

Download Arduino Code

You are so close to to being done with setup! Download the SIK Guide Code. Click the following link to download the code:

Copy “SIK Guide Code” into “examples” folder in the Arduino folder.

Window Users: Unzip the file “SIK Guide Code”. It should be located in your browser’s “Downloads” folder. Right click the zipped folder and choose “unzip”. Copy the “SIK Guide Code” folder into Arduino’s folder named “examples”.

Mac Users: Unzip the file “SIK Guide Code”. It should be located in your browser’s “Downloads” folder. Right click the zipped folder and choose “unzip”. Find “Arduino” in your applications folder. Right click (ctrl + click) on “Arduino”. Select “Show Package Contents”. Then, click through folders Contents > Resources > Java > examples. Copy the “SIK Guide Code” folder into Arduino’s folder named “examples”.

Linux Users: Please visit the Arduino Learning Linux section, to learn more about Arduino on Linux.

Suggested Reading

Before continuing on with this tutorial, we recommend you be somewhat familiar with the concepts in the following tutorial:

- How to Use a Breadboard - First time working with a breadboard? Please check out this tutorial! It will help you understand why the breadboard is a great for prototyping and how to use one.

Time for the fun part!

Continue on to the first experiment and in no time you will be blinking an LED!

**Experiment 1: Blinking an LED**

Introduction

LEDs are small, powerful lights that are used in many different applications. To start off, we will work on blinking an LED, the Hello World of microcontrollers. That’s right - it’s as simple as turning a light on and off. It might not seem like much, but establishing this important baseline will give you a solid foundation as we work toward more complex experiments.

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x RedBoard or Arduino Uno R3

- 1x LED

- 1x 330Ω Resistor

- 2x Jumper Wires

Didn’t get the SIK?

If you are following through this experiment and didn’t get the SIK, we suggest using these parts:

![Breadboard - Self-Adhesive (White)]()

In stock

PRT-12002

**Description**: This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a t…

4.95

![Jumper Wires Standard 7" M/M Pack of 30]()

In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

4.95

![Resistor 330 Ohm 1/6 Watt PTH - 20 pack]()

In stock

COM-11507

1/6 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 330Ohm resistors make excellent…

0.95

![LED - Assorted (20 pack)]()

In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

2.95

You will also need either a RedBoard or Arduino Uno R3.

![RedBoard - Programmed with Arduino]()

Only 5 left!

DEV-12757

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

19.95

![Arduino Uno- R3 SMD]()

In stock

DEV-11224

This is the new Arduino Uno R3. In addition to all the features of the previous board, the Uno now uses an ATmega16U2 instead…

29.95

Suggested Reading

Before continuing on with this experiment, we recommend you be familiar with the concepts in the following tutorial:

Hardware Hookup

Ready to start hooking everything up? Check out the Fritzing diagram and hookup table below, to see how everything is connected. Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components are highlighted with a yellow warning triangle, in the table. Polarized components can only be connected to a circuit in one direction.

Please note: Pay close attention to the LED. The negative side of the LED is the short leg, marked with a flat edge.

![LED drawing]()

Components like resistors need to have their legs bent into 90° angles in order to correctly fit the breadboard sockets. You can also cut the legs shorter to make them easier to work with on the breadboard.

![Bent resistor]()

Fritzing Diagram for RedBoard

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Fritzing Diagram for Arduino

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Hookup Table

| Component | RedBoard or Arduino Uno R3 | Breadboard | Breadboard |

|---|

| LED | | c2 LED ( + ) | c3 LED ( - ) |

| 330 Resistor | | a3 | ( - ) |

| Jumper Wire | GND | ( - ) | |

| Jumper Wire | PIN 13 | e2 | |

In the table, polarized components are highlighted in yellow for the whole row and a warning triangle. Polarized components only be connected to a circuit in one direction.

Open Your First Sketch

Open Up the Arduino IDE software on your computer. Coding in the Arduino language will control your circuit. Open the code for Circuit 1 by accessing the “SIK Guide Code” you downloaded and placed into your “examples” folder earlier.

To open the code go to: File > Examples > SIK Guide Code > Circuit_01

![alt text]()

You can also copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Inventor's Kit

Example sketch 01

BLINKING A LED

Turn an LED on for one second, off for one second,

and repeat forever.

Hardware connections:

Most Arduinos already have an LED and resistor connected to

pin 13, so you may not need any additional circuitry.

But if you'd like to connect a second LED to pin 13, or use

a different pin, follow these steps:

Connect the positive side of your LED (longer leg) to Arduino

digital pin 13 (or another digital pin, don't forget to change

the code to match).

Connect the negative side of your LED (shorter leg) to a

330 Ohm resistor (orange-orange-brown). Connect the other side

of the resistor to ground.

pin 13 _____ + LED - _____ 330 Ohm _____ GND

(We always use resistors between the Arduino and and LEDs

to keep the LEDs from burning out due to too much current.)

This sketch was written by SparkFun Electronics,

with lots of help from the Arduino community.

This code is completely free for any use.

Visit http://learn.sparkfun.com/products/2 for SIK information.

Visit http://www.arduino.cc to learn about the Arduino.

Version 2.0 6/2012 MDG

*/

// Welcome to Arduino!

// If you're brand-new to this, there will be some new things to

// learn, but we'll jump right in and explain things as we go.

// The Arduino is a tiny computer that runs programs called

// "sketches". These are text files written using instructions

// the computer understances. You're reading a sketch right now.

// Sketches have computer code in them, but also (hopefully)

// "comments" that explain what the code does. Comments and code

// will have different colors in the editor so you can tell them

// apart.

// This is a comment - anything on a line after "//" is ignored

// by the computer.

/* This is also a comment - this one can be multi-line, but it

must start and end with these characters */

// A "function" is a named block of code, that performs a specific,

// well, function. Many useful functions are already built-in to

// the Arduino; others you'll name and write yourself for your

// own purposes.

// All Arduino sketches MUST have two specific functions, named

// "setup()" and "loop()". The Arduino runs these functions

// automatically when it starts up or if you press the reset

// button. You'll typically fill these function "shells" with your

// own code. Let's get started!

// The setup() function runs once when the sketch starts.

// You'll use it for things you need to do first, or only once:

void setup()

{

// The Arduino has 13 digital input/output pins. These pins

// can be configured as either inputs or outputs. We set this

// up with a built-in function called pinMode().

// The pinMode() function takes two values, which you type in

// the parenthesis after the function name. The first value is

// a pin number, the second value is the word INPUT or OUTPUT.

// Here we'll set up pin 13 (the one connected to a LED) to be

// an output. We're doing this because we need to send voltage

// "out" of the Arduino to the LED.

pinMode(13, OUTPUT);

// By the way, the Arduino offers many useful built-in functions

// like this one. You can find information on all of them at the

// Arduino website: http://arduino.cc/en/Reference

}

// After setup() finishes, the loop() function runs over and over

// again, forever (or until you turn off or reset the Arduino).

// This is usually where the bulk of your program lives:

void loop()

{

// The 13 digital pins on your Arduino are great at inputting

// and outputting on/off, or "digital" signals. These signals

// will always be either 5 Volts (which we call "HIGH"), or

// 0 Volts (which we call "LOW").

// Because we have an LED connected to pin 13, if we make that

// output HIGH, the LED will get voltage and light up. If we make

// that output LOW, the LED will have no voltage and turn off.

// digitalWrite() is the built-in function we use to make an

// output pin HIGH or LOW. It takes two values; a pin number,

// followed by the word HIGH or LOW:

digitalWrite(13, HIGH); // Turn on the LED

// delay() is a function that pauses for a given amount of time.

// It takes one value, the amount of time to wait, measured in

// milliseconds. There are 1000 milliseconds in a second, so if

// you delay(1000), it will pause for exactly one second:

delay(1000); // Wait for one second

digitalWrite(13, LOW); // Turn off the LED

delay(1000); // Wait for one second

// All together, the above code turns the LED on, waits one

// second, turns it off, and waits another second.

// When the computer gets to the end of the loop() function,

// it starts loop() over again. So this program will continue

// blinking the LED on and off!

// Try changing the 1000 in the above delay() functions to

// different numbers and see how it affects the timing. Smaller

// values will make the loop run faster. (Why?)

}

Code to Note

pinMode(13, OUTPUT);

Before you can use one of the Arduino’s pins, you need to tell the RedBoard or Arduino Uno R3 whether it is an INPUT or OUTPUT. We use a built-in “function” called pinMode() to do this.

digitalWrite(13, HIGH);

When you’re using a pin as an OUTPUT, you can command it to be HIGH (output 5 volts), or LOW (output 0 volts).

What You Should See

You should see your LED blink on and off. If it isn’t, make sure you have assembled the circuit correctly and verified and uploaded the code to your board, or see the troubleshooting section.

Real World Application

Almost all modern flat screen televisions and monitors have LED indicator lights to show they are on or off.

![alt text]()

Troubleshooting

Program Not Uploading

This happens sometimes, the most likely cause is a confused serial port, you can change this in tools > serial port >

Still No Success?

A broken circuit is no fun, send us an e-mail and we will get back to you as soon as we can: techsupport@sparkfun.com

**Experiment 2: Reading a Potentiometer**

Introduction

In this circuit you’ll work with a potentiometer.

A potentiometer is also known as a variable resistor. When powered with 5V, the middle pin outputs a voltage between 0V and 5V, depending on the position of the knob on the potentiometer. A potentiometer is a perfect demonstration of a variable voltage divider circuit. The voltage is divided proportionate to the resistance between the middle pin and the ground pin. In this circuit, you’ll learn how to use a potentiometer to control the brightness of an LED.

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x RedBoard or Arduino Uno

- 1x LED

- 1x 330Ω Resistor

- 6x Jumper Wires

- 1x Potentiometer

Didn’t get the SIK?

If you are following through this experiment and didn’t get the SIK, we suggest using these parts:

![Trimpot 10K with Knob]()

In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

0.95

![Breadboard - Self-Adhesive (White)]()

In stock

PRT-12002

**Description**: This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a t…

4.95

![Jumper Wires Standard 7" M/M Pack of 30]()

In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

4.95

![Resistor 330 Ohm 1/6 Watt PTH - 20 pack]()

In stock

COM-11507

1/6 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 330Ohm resistors make excellent…

0.95

![LED - Assorted (20 pack)]()

In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

2.95

You will also need either the RedBoard or Arduino Uno R3.

![RedBoard - Programmed with Arduino]()

Only 5 left!

DEV-12757

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

19.95

![Arduino Uno- R3 SMD]()

In stock

DEV-11224

This is the new Arduino Uno R3. In addition to all the features of the previous board, the Uno now uses an ATmega16U2 instead…

29.95

Suggested Reading

Before continuing on with this experiment, we recommend you be familiar with the concepts in the following tutorial:

Hardware Hookup

Ready to start hooking everything up? Check out the Fritzing diagram and hookup table below, to see how everything is connected. Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components only be connected to a circuit in one direction.

Fritzing Diagram for RedBoard

![RedBoard Fritzing Potentiometer]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Fritzing Diagram for Arduino

![Arduino Uno Fritzing Potentiometer]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Hookup Table

| Component | RedBoard or Arduino Uno R3 | Breadboard | Breadboard | Breadboard |

|---|

| 330 Resistor | | j21 | ( - ) | |

| LED | | h20 | LED ( + ) | h21 | LED ( - ) | |

| Potentiometer | | a6 | a7 | a8 |

| Jumper Wire | | e6 | ( - ) | |

| Jumper Wire | A0 | e7 | | |

| Jumper Wire | | e8 | ( + ) | |

| Jumper Wire | PIN 13 | j20 | | |

| Jumper Wire | 5V | ( + ) | | |

| Jumper Wire | GND | ( - ) | | |

In the table, polarized components are highlighted in yellow for the whole row and a warning triangle. Polarized components only be connected to a circuit in one direction.

Open the Sketch

Open Up the Arduino IDE software on your computer. Coding in the Arduino language will control your circuit. Open the code for Circuit 2 by accessing the “SIK Guide Code” you downloaded and placed into your “Examples” folder earlier.

To open the code go to: File > examples > SIK Guide Code > Circuit_02

Copy and paste the following code into the Arduino IDE. Hit upload and see what happens!

language:cpp

/* SparkFun Inventor's Kit

Example sketch 02

POTENTIOMETER

Measure the position of a potentiometer and use it to

control the blink rate of an LED. Turn the knob to make

it blink faster or slower!

What's a potentiometer?

A potentiometer, or "pot" for short, is a control knob.

It's the same type of control you'd use to change volume,

dim a lamp, etc. A potentiometer changes resistance as it

is turned. By using it as a "voltage divider", the Arduino

can sense the position of the knob, and use that value to

control whatever you wish (like the blink rate of an LED,

as we're doing here).

Hardware connections:

Potentiometer:

Potentiometers have three pins. When we're using it as a

voltage divider, we connect the outside pins to power and

ground. The middle pin will be the signal (a voltage which

varies from 0 Volts to 5 Volts depending on the position of

the knob).

Connect the middle pin to ANALOG IN pin 0 on the Galileo.

Connect one of the outside pins to 5V.

Connect the other outside pin to GND.

(TIP: if once your program is running, the knob feels

"backwards", you can swap the 5V and GND pins to reverse

the direction.)

LED:

Most Arduinos already have an LED and resistor connected to

pin 13, so you may not need any additional circuitry.

But if you'd like to connect a second LED to pin 13, or use

a different pin, follow these steps:

Connect the positive side of your LED (longer leg) to

Arduino digital pin 13 (or another digital pin, but don't

forget to change the code to match).

Connect the negative side of your LED (shorter leg) to a

330 Ohm resistor (orange-orange-brown).

Connect the other side of the resistor to ground.

This sketch was written by SparkFun Electronics,

with lots of help from the Arduino community.

This code is completely free for any use.

Visit http://learn.sparkfun.com/products/2 for SIK information.

Visit http://www.arduino.cc to learn about the Arduino.

Version 2.0 6/2012 MDG

*/

// Welcome back! In this sketch we'll start using "variables".

// A variable is a named number. We'll often use these to store

// numbers that change, such as measurements from the outside

// world, or to make a sketch easier to understand (sometimes a

// descriptive name makes more sense than looking at a number).

// Variables can be different "data types", which is the kind of

// number we're using (can it be negative? Have a decimal point?)

// We'll introduce more data types later, but for the moment we'll

// stick with good old "integers" (called "int" in your sketch).

// Integers are whole numbers (0, 3, 5643), can be negative, and

// for reasons we won't go into right now, can range from -32768

// to 32767. (Don't worry, if you need to work with larger numbers,

// there are other data types for that. See:

// http://arduino.cc/en/Reference/VariableDeclaration

// for a list of all the data types you can use).

// You must "declare" variables before you use them, so that the

// computer knows about them. Here we'll declare two integer

// variables, and at the same time, initialize them to specific

// values. We're doing this so that further down, we can refer to

// the pins by name rather than number.

// Note that variable names are case-sensitive! If you get an

// "(variable) was not declared in this scope" error, double-check

// that you typed the name correctly.

// Here we're creating a variable called "sensorPin" of type "int"

// and initializing it to have the value "0":

int sensorPin = 0; // The potentiometer is connected to

// analog pin 0

int ledPin = 13; // The LED is connected to digital pin 13

// One more thing. If you declare variables outside of a function,

// as we have here, they are called "global variables" and can be

// seen by all the functions. If you declare variables within a

// function, they can only be seen within that function. It's good

// practice to "limit the scope" of a variable whenever possible,

// but as we're getting started, global variables are just fine.

void setup() // this function runs once when the sketch starts up

{

// We'll be using pin 13 to light a LED, so we must configure it

// as an output.

// Because we already created a variable called ledPin, and

// set it equal to 13, we can use "ledPin" in place of "13".

// This makes the sketch easier to follow.

pinMode(ledPin, OUTPUT);

// The above line is the same as "pinMode(13, OUTPUT);"

// You might be wondering why we're not also configuring

// sensorPin as an input. The reason is that this is an

// "analog in" pin. These pins have the special ability to

// read varying voltages from sensors like the potentiometer.

// Since they're always used as inputs, there is no need to

// specifically configure them.

}

void loop() // this function runs repeatedly after setup() finishes

{

// First we'll declare another integer variable

// to store the value of the potentiometer:

int sensorValue;

// The potentiometer is set up as a voltage divider, so that

// when you turn it, the voltage on the center pin will vary

// from 0V to 5V. We've connected the center pin on the

// potentiometer to the Arduino's analog input 0.

// The Arduino can read external voltages on the analog input

// pins using a built-in function called analogRead(). This

// function takes one input value, the analog pin we're using

// (sensorPin, which we earlier set to 0). It returns an integer

// number that ranges from 0 (0 Volts) to 1023 (5 Volts).

// We're sticking this value into the sensorValue variable:

sensorValue = analogRead(sensorPin);

// Now we'll blink the LED like in the first example, but we'll

// use the sensorValue variable to change the blink speed

// (the smaller the number, the faster it will blink).

// Note that we're using the ledPin variable here as well:

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(sensorValue); // Pause for sensorValue

// milliseconds

digitalWrite(ledPin, LOW); // Turn the LED off

delay(sensorValue); // Pause for sensorValue

// milliseconds

// Remember that loop() repeats forever, so we'll do all this

// again and again.

}

Code To Note

int sensorValue;

A “variable” is a placeholder for values that may change in your code. You must introduce, or “declare” variables before you use them; here we’re declaring a variable called sensorValue, of type “int” (integer). Don’t forget that variable names are case-sensitive!

sensorValue = analogRead(sensorPin);

We use the analogRead() function to read the value on an analog pin. analogRead() takes one parameter, the analog pin you want to use (“sensorPin”), and returns a number (“sensorValue”) between 0 (0 volts) and 1023 (5 volts).

delay(sensorValue);

Microcontrollers are very fast, capable of running thousands of lines of code each second. To slow it down so that we can see what it’s doing, we’ll often insert delays into the code. delay() counts in milliseconds; there are 1000 ms in one second.

What You Should See

You should see the LED blink faster or slower in accordance with your potentiometer. If it isn’t working, make sure you have assembled the circuit correctly and verified and uploaded the code to your board, or see the troubleshooting section.

Real World Application

Most traditional volume knobs employ a potentiometer.

Troubleshooting

Sporadically Working

This is most likely due to a slightly dodgy connection with the potentiometer’s pins. This can usually be conquered by holding the potentiometer down.

Not Working

Make sure you haven’t accidentally connected the wiper, the resistive element in the potentiometer, to digital pin 0 rather than analog pin 0. (the row of pins beneath the power pins).

LED Not Lighting Up?

LEDs will only work in one direction. Double check your connections.

**Experiment 3: Driving and RGB LED**

Introduction

You know what’s even more fun than a blinking LED? Changing colors with one LED. RGB, or red-green-blue, LEDs have three different color-emitting diodes that can be combined to create all sorts of colors. In this circuit, you’ll learn how to use an RGB LED to create unique color combinations. Depending on how bright each diode is, nearly any color is possible!

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x RedBoard or Arduino Uno

- 1x LED - RGB Common Cathode

- 3x 330Ω Resistors

- 5x Jumper Wires

Didn’t get the SIK?

If you are following through this experiment and didn’t get the SIK, we suggest using these parts:

![Breadboard - Self-Adhesive (White)]()

In stock

PRT-12002

**Description**: This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a t…

4.95

![LED - RGB Clear Common Cathode]()

In stock

COM-00105

Ever hear of a thing called RGB? Red, Green, Blue? How about an RGB LED? These 5mm units have four pins - Cathode is the long…

1.95

![Jumper Wires Standard 7" M/M Pack of 30]()

In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

4.95

![Resistor 330 Ohm 1/6 Watt PTH - 20 pack]()

In stock

COM-11507

1/6 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 330Ohm resistors make excellent…

0.95

You will also need either the RedBoard or Arduino Uno R3.

![RedBoard - Programmed with Arduino]()

Only 5 left!

DEV-12757

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

19.95

![Arduino Uno- R3 SMD]()

In stock

DEV-11224

This is the new Arduino Uno R3. In addition to all the features of the previous board, the Uno now uses an ATmega16U2 instead…

29.95

Hardware Hookup

Ready to start hooking everything up? Check out the Fritzing diagram and hookup table below, to see how everything is connected. Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components are highlighted with a yellow warning triangle, in the table. Polarized components can only be connected to a circuit in one direction.

Fritzing Diagram for RedBoard

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Fritzing Diagram for Arduino

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Hookup Table

| Component | RedBoard or Arduino Uno R3 | Breadboard | Breadboard | Breadboard | Breadboard |

|---|

| RGB LED | | j2 (RED) | j3 (GND) | j4 (GREEN) | j5 (BLUE) |

| 330 Resistor | | d2 | f2 | | |

| 330 Resistor | | d4 | f4 | | |

| 330 Resistor | | d5 | f5 | | |

| Jumper Wire | GND | ( - ) | | | |

| Jumper Wire | PIN 9 | a2 | | | |

| Jumper Wire | | f3 | ( - ) | | |

| Jumper Wire | PIN 10 | a4 | | | |

| Jumper Wire | PIN 11 | a5 | | | |

Open the Sketch

Open Up the Arduino IDE software on your computer. Coding in the Arduino language will control your circuit. Open the code for Circuit 3 by accessing the “SIK Guide Code” you downloaded and placed into your “Examples” folder earlier.

To open the code go to: File > examples > SIK Guide Code > Circuit_03

You can also copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Inventor's Kit

Example sketch 03

RGB LED

Make an RGB LED display a rainbow of colors!

Hardware connections:

An RGB LED is actually three LEDs (red, green, and blue) in

one package. When you run them at different brightnesses,

the red, green and blue mix to form new colors.

Starting at the flattened edge of the flange on the LED,

the pins are ordered RED, COMMON, GREEN, BLUE.

Connect RED to a 330 ohm resistor. Connect the other end

of the resistor to Arduino digital pin 9.

Connect COMMON pin to GND.

Connect GREEN to a 330 ohm resistor. Connect the other end

of the resistor to Arduino digital pin 10.

Connect BLUE to a 330 ohm resistor. Connect the other end

of the resistor to Arduino digital pin 11.

This sketch was written by SparkFun Electronics,

with lots of help from the Arduino community.

Visit http://learn.sparkfun.com/products/2 for SIK information.

Visit http://www.arduino.cc to learn about the Arduino.

Version 2.0 6/2012 MDG

*/

// First we'll define the pins by name to make the sketch

// easier to follow.

// Here's a new trick: putting the word "const" in front of a

// variable indicates that this is a "constant" value that will

// never change. (You don't have to do this, but if you do, the

// Arduino will give you a friendly warning if you accidentally

// try to change the value, so it's considered good form.)

const int RED_PIN = 9;

const int GREEN_PIN = 10;

const int BLUE_PIN = 11;

// This variable controls how fast we loop through the colors.

// (Try changing this to make the fading faster or slower.)

int DISPLAY_TIME = 100; // In milliseconds

void setup()

{

// Here we'll configure the Arduino pins we're using to

// drive the LED to be outputs:

pinMode(RED_PIN, OUTPUT);

pinMode(GREEN_PIN, OUTPUT);

pinMode(BLUE_PIN, OUTPUT);

}

void loop()

{

// In this sketch, we'll start writing our own functions.

// This makes the sketch easier to follow by dividing up

// the sketch into sections, and not having everything in

// setup() or loop().

// We'll show you two ways to run the RGB LED.

// The first way is to turn the individual LEDs (red, blue,

// and green) on and off in various combinations. This gives you

// a total of eight colors (if you count "black" as a color).

// We've written a function called mainColors() that steps

// through all eight of these colors. We're only "calling" the

// function here (telling it to run). The actual function code

// is further down in the sketch.

mainColors();

// The above function turns the individual LEDs full-on and

// full-off. If you want to generate more than eight colors,

// you can do so by varying the brightness of the individual

// LEDs between full-on and full-off.

// The analogWrite() function lets us do this. This function

// lets you dim a LED from full-off to full-on over 255 steps.

// We've written a function called showSpectrum() that smoothly

// steps through all the colors. Again we're just calling it

// here; the actual code is further down in this sketch.

showSpectrum();

}

// Here's the mainColors() function we've written.

// This function displays the eight "main" colors that the RGB LED

// can produce. If you'd like to use one of these colors in your

// own sketch, you cancopy and paste that section into your code.

void mainColors()

{

// Off (all LEDs off):

digitalWrite(RED_PIN, LOW);

digitalWrite(GREEN_PIN, LOW);

digitalWrite(BLUE_PIN, LOW);

delay(1000);

// Red (turn just the red LED on):

digitalWrite(RED_PIN, HIGH);

digitalWrite(GREEN_PIN, LOW);

digitalWrite(BLUE_PIN, LOW);

delay(1000);

// Green (turn just the green LED on):

digitalWrite(RED_PIN, LOW);

digitalWrite(GREEN_PIN, HIGH);

digitalWrite(BLUE_PIN, LOW);

delay(1000);

// Blue (turn just the blue LED on):

digitalWrite(RED_PIN, LOW);

digitalWrite(GREEN_PIN, LOW);

digitalWrite(BLUE_PIN, HIGH);

delay(1000);

// Yellow (turn red and green on):

digitalWrite(RED_PIN, HIGH);

digitalWrite(GREEN_PIN, HIGH);

digitalWrite(BLUE_PIN, LOW);

delay(1000);

// Cyan (turn green and blue on):

digitalWrite(RED_PIN, LOW);

digitalWrite(GREEN_PIN, HIGH);

digitalWrite(BLUE_PIN, HIGH);

delay(1000);

// Purple (turn red and blue on):

digitalWrite(RED_PIN, HIGH);

digitalWrite(GREEN_PIN, LOW);

digitalWrite(BLUE_PIN, HIGH);

delay(1000);

// White (turn all the LEDs on):

digitalWrite(RED_PIN, HIGH);

digitalWrite(GREEN_PIN, HIGH);

digitalWrite(BLUE_PIN, HIGH);

delay(1000);

}

// Below are two more functions we've written,

// showSpectrum() and showRGB().

// showRGB() displays a single color on the RGB LED.

// You call showRGB() with the number of a color you want

// to display.

// showSpectrum() steps through all the colors of the RGB LED,

// displaying a rainbow. showSpectrum() actually calls showRGB()

// over and over to do this.

// We'll often break tasks down into individual functions like

// this, which makes your sketches easier to follow, and once

// you have a handy function, you can reuse it in your other

// programs.

// showSpectrum()

// This function steps through all the colors of the RGB LED.

// It does this by stepping a variable from 0 to 768 (the total

// number of colors), and repeatedly calling showRGB() to display

// the individual colors.

// In this function, we're using a "for() loop" to step a variable

// from one value to another, and perform a set of instructions

// for each step. For() loops are a very handy way to get numbers

// to count up or down.

// Every for() loop has three statements separated by semicolons:

// 1. Something to do before starting

// 2. A test to perform; as long as it's true,

// it will keep looping

// 3. Something to do after each loop (usually

// increase a variable)

// For the for() loop below, these are the three statements:

// 1. x = 0; Before starting, make x = 0.

// 2. x < 768; While x is less than 768, run the

// following code.

// 3. x++ Putting "++" after a variable means

// "add one to it". (You can also use "x = x + 1")

// Every time you go through the loop, the statements following

// the loop (those within the brackets) will run.

// And when the test in statement 2 is finally false, the sketch

// will continue.

void showSpectrum()

{

int x; // define an integer variable called "x"

// Now we'll use a for() loop to make x count from 0 to 767

// (Note that there's no semicolon after this line!

// That's because the for() loop will repeat the next

// "statement", which in this case is everything within

// the following brackets {} )

for (x = 0; x < 768; x++)

// Each time we loop (with a new value of x), do the following:

{

showRGB(x); // Call RGBspectrum() with our new x

delay(10); // Delay for 10 ms (1/100th of a second)

}

}

// showRGB()

// This function translates a number between 0 and 767 into a

// specific color on the RGB LED. If you have this number count

// through the whole range (0 to 767), the LED will smoothly

// change color through the entire spectrum.

// The "base" numbers are:

// 0 = pure red

// 255 = pure green

// 511 = pure blue

// 767 = pure red (again)

// Numbers between the above colors will create blends. For

// example, 640 is midway between 512 (pure blue) and 767

// (pure red). It will give you a 50/50 mix of blue and red,

// resulting in purple.

// If you count up from 0 to 767 and pass that number to this

// function, the LED will smoothly fade between all the colors.

// (Because it starts and ends on pure red, you can start over

// at 0 without any break in the spectrum).

void showRGB(int color)

{

int redIntensity;

int greenIntensity;

int blueIntensity;

// Here we'll use an "if / else" statement to determine which

// of the three (R,G,B) zones x falls into. Each of these zones

// spans 255 because analogWrite() wants a number from 0 to 255.

// In each of these zones, we'll calculate the brightness

// for each of the red, green, and blue LEDs within the RGB LED.

if (color <= 255) // zone 1

{

redIntensity = 255 - color; // red goes from on to off

greenIntensity = color; // green goes from off to on

blueIntensity = 0; // blue is always off

}

else if (color <= 511) // zone 2

{

redIntensity = 0; // red is always off

greenIntensity = 255 - (color - 256); // green on to off

blueIntensity = (color - 256); // blue off to on

}

else // color >= 512 // zone 3

{

redIntensity = (color - 512); // red off to on

greenIntensity = 0; // green is always off

blueIntensity = 255 - (color - 512); // blue on to off

}

// Now that the brightness values have been set, command the LED

// to those values

analogWrite(RED_PIN, redIntensity);

analogWrite(BLUE_PIN, blueIntensity);

analogWrite(GREEN_PIN, greenIntensity);

}

Code To Note

language:cpp

for (x = 0; x < 768; x++)

{}

A for() loop is used to repeat an action a set number of times across a range, and repeatedly runs code within the brackets {}. Here the variable “x” starts a 0, ends at 767, and increases by one each time (“x++”).

language:cpp

if (x <= 255)

{}

else

{}

“If / else” statements are used to make choices in your programs. The statement within the parenthesis () is evaluated; if it’s true, the code within the first brackets {} will run. If it’s not true, the code within the second brackets {} will run.

What You Should See

You should see your LED turn on, but this time in new, crazy colors! If it isn’t, make sure you have assembled the circuit correctly and verified and uploaded the code to your board or see the troubleshooting section.

Real World Application

Many electronics such as video game consoles use RGB LEDs to have the versatility to show different colors in the same area. Often times the different colors represent different states of working condition.

Troubleshooting

LED Remains Dark or Shows Incorrect Color

With the four pins of the LED so close together, it’s sometimes easy to misplace one. Double check each pin is where it should be.

Seeing Red

The red diode within the RGB LED may be a bit brighter than the other two. To make your colors more balanced, use a higher ohm resistor. Or adjust in code.

analogWrite(RED_PIN, redIntensity);

to

analogWrite(RED_PIN, redIntensity/3);

**Experiment 4: Driving Multiple LEDs**

Introduction

Now that you’ve gotten your LED to blink on and off, it’s time to up the stakes a little bit – by connecting eight LEDs at once. We’ll also give your RedBoard or Arduino R3 a little test by creating various lighting sequences. This circuit is a great setup to start practicing writing your own programs and getting a feel for the way Arduino works.

Along with controlling the LEDs, you’ll learn about a couple programming tricks that keep your code neat and tidy:

for() loops - used when you want to run a piece of code several times

arrays[ ] - used to make managing variables easier by grouping them together

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x RedBoard or Arduino Uno

- 8x LEDs

- 8x 330Ω Resistors

- 9x Jumper Wires

Didn’t get the SIK?

If you are following through this experiment and didn’t get the SIK, we suggest using these parts:

![Breadboard - Self-Adhesive (White)]()

In stock

PRT-12002

**Description**: This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a t…

4.95

![Jumper Wires Standard 7" M/M Pack of 30]()

In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

4.95

![Resistor 330 Ohm 1/6 Watt PTH - 20 pack]()

In stock

COM-11507

1/6 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 330Ohm resistors make excellent…

0.95

![LED - Assorted (20 pack)]()

In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

2.95

You will also need either a RedBoard or Arduino Uno R3.

![RedBoard - Programmed with Arduino]()

Only 5 left!

DEV-12757

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

19.95

![Arduino Uno- R3 SMD]()

In stock

DEV-11224

This is the new Arduino Uno R3. In addition to all the features of the previous board, the Uno now uses an ATmega16U2 instead…

29.95

Hardware Hookup

Ready to start hooking everything up? Check out the Fritzing diagram and hookup table below, to see how everything is connected. Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction.

Fritzing Diagram for RedBoard

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Fritzing Diagram for Arduino

![alt text]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Open the Sketch

Open Up the Arduino IDE software on your computer. Coding in the Arduino language will control your circuit. Open the code for Circuit 4 by accessing the “SIK Guide Code” you downloaded and placed into your “Examples” folder earlier.

To open the code go to: File > examples > SIK Guide Code > Circuit_04

You can also copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Inventor's Kit

Example sketch 04

MULTIPLE LEDs

Make eight LEDs dance. Dance LEDs, dance!

Hardware connections:

You'll need eight LEDs, and eight 330 Ohm resistors

(orange-orange-brown).

For each LED, connect the negative side (shorter leg)

to a 330 Ohm resistor.

Connect the other side of the resistors to GND.

Connect the positive side (longer leg) of the LEDs

to Arduino digital pins 2 through 9.

This sketch was written by SparkFun Electronics,

with lots of help from the Arduino community.

This code is completely free for any use.

Visit http://learn.sparkfun.com/products/2 for SIK information.

Visit http://www.arduino.cc to learn about the Arduino.

Version 2.0 6/2012 MDG

*/

// To keep track of all the LED pins, we'll use an "array".

// An array lets you store a group of variables, and refer to them

// by their position, or "index". Here we're creating an array of

// eight integers, and initializing them to a set of values:

int ledPins[] = {2,3,4,5,6,7,8,9};

// The first element of an array is index 0.

// We've put the value "2" in index 0, "3" in index 1, etc.

// The final index in the above array is 7, which contains

// the value "9".

// We're using the values in this array to specify the pin numbers

// that the eight LEDs are connected to. LED 0 is connected to

// pin 2, LED 1 is connected to pin 3, etc.

void setup()

{

int index;

// In this sketch, we'll use "for() loops" to step variables from

// one value to another, and perform a set of instructions for

// each step. For() loops are a very handy way to get numbers to

// count up or down.

// Every for() loop has three statements separated by

// semicolons (;):

// 1. Something to do before starting

// 2. A test to perform; as long as it's true, keep looping

// 3. Something to do after each loop (increase a variable)

// For the for() loop below, these are the three statements:

// 1. index = 0; Before starting, make index = 0.

// 2. index <= 7; If index is less or equal to 7,

// run the following code.

// (When index = 8, continue with the sketch.)

// 3. index++ Putting "++" after a variable means

// "add one to it".

// (You can also use "index = index + 1".)

// Every time you go through the loop, the statements following

// the for() (within the brackets) will run.

// When the test in statement 2 is finally false, the sketch

// will continue.

// Here we'll use a for() loop to initialize all the LED pins

// to outputs. This is much easier than writing eight separate

// statements to do the same thing.

// This for() loop will make index = 0, then run the pinMode()

// statement within the brackets. It will then do the same thing

// for index = 2, index = 3, etc. all the way to index = 7.

for(index = 0; index <= 7; index++)

{

pinMode(ledPins[index],OUTPUT);

// ledPins[index] is replaced by the value in the array.

// For example, ledPins[0] is 2

}

}

void loop()

{

// This loop() calls functions that we've written further below.

// We've disabled some of these by commenting them out (putting

// "//" in front of them). To try different LED displays, remove

// the "//" in front of the ones you'd like to run, and add "//"

// in front of those you don't to comment out (and disable) those

// lines.

oneAfterAnotherNoLoop(); // Light up all the LEDs in turn

//oneAfterAnotherLoop(); // Same as oneAfterAnotherNoLoop,

// but with much less typing

//oneOnAtATime(); // Turn on one LED at a time,

// scrolling down the line

//pingPong(); // Light the LEDs middle to the edges

//marquee(); // Chase lights like you see on signs

//randomLED(); // Blink LEDs randomly

}

/*

oneAfterAnotherNoLoop()

This function will light one LED, delay for delayTime, then light

the next LED, and repeat until all the LEDs are on. It will then

turn them off in the reverse order.

This function does NOT use a for() loop. We've done it the hard way

to show you how much easier life can be when you use for() loops.

Take a look at oneAfterAnotherLoop() further down, which does

exactly the same thing with much less typing.

*/

void oneAfterAnotherNoLoop()

{

int delayTime = 100; // time (milliseconds) to pause between LEDs

// make this smaller for faster switching

// turn all the LEDs on:

digitalWrite(ledPins[0], HIGH); //Turns on LED #0 (pin 2)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[1], HIGH); //Turns on LED #1 (pin 3)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[2], HIGH); //Turns on LED #2 (pin 4)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[3], HIGH); //Turns on LED #3 (pin 5)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[4], HIGH); //Turns on LED #4 (pin 6)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[5], HIGH); //Turns on LED #5 (pin 7)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[6], HIGH); //Turns on LED #6 (pin 8)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[7], HIGH); //Turns on LED #7 (pin 9)

delay(delayTime); //wait delayTime milliseconds

// turn all the LEDs off:

digitalWrite(ledPins[7], LOW); //Turn off LED #7 (pin 9)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[6], LOW); //Turn off LED #6 (pin 8)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[5], LOW); //Turn off LED #5 (pin 7)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[4], LOW); //Turn off LED #4 (pin 6)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[3], LOW); //Turn off LED #3 (pin 5)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[2], LOW); //Turn off LED #2 (pin 4)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[1], LOW); //Turn off LED #1 (pin 3)

delay(delayTime); //wait delayTime milliseconds

digitalWrite(ledPins[0], LOW); //Turn off LED #0 (pin 2)

delay(delayTime); //wait delayTime milliseconds

}

/*

oneAfterAnotherLoop()

This function does exactly the same thing as oneAfterAnotherNoLoop(),

but it takes advantage of for() loops and the array to do it with

much less typing.

*/

void oneAfterAnotherLoop()

{

int index;

int delayTime = 100; // milliseconds to pause between LEDs

// make this smaller for faster switching

// Turn all the LEDs on:

// This for() loop will step index from 0 to 7

// (putting "++" after a variable means add one to it)

// and will then use digitalWrite() to turn that LED on.

for(index = 0; index <= 7; index++)

{

digitalWrite(ledPins[index], HIGH);

delay(delayTime);

}

// Turn all the LEDs off:

// This for() loop will step index from 7 to 0

// (putting "--" after a variable means subtract one from it)

// and will then use digitalWrite() to turn that LED off.

for(index = 7; index >= 0; index--)

{

digitalWrite(ledPins[index], LOW);

delay(delayTime);

}

}

/*

oneOnAtATime()

This function will step through the LEDs,

lighting only one at at time.

*/

void oneOnAtATime()

{

int index;

int delayTime = 100; // milliseconds to pause between LEDs

// make this smaller for faster switching

// step through the LEDs, from 0 to 7

for(index = 0; index <= 7; index++)

{

digitalWrite(ledPins[index], HIGH); // turn LED on

delay(delayTime); // pause to slow down

digitalWrite(ledPins[index], LOW); // turn LED off

}

}

/*

pingPong()

This function will step through the LEDs,

lighting one at at time in both directions.

*/

void pingPong()

{

int index;

int delayTime = 100; // milliseconds to pause between LEDs

// make this smaller for faster switching

// step through the LEDs, from 0 to 7

for(index = 0; index <= 7; index++)

{

digitalWrite(ledPins[index], HIGH); // turn LED on

delay(delayTime); // pause to slow down

digitalWrite(ledPins[index], LOW); // turn LED off

}

// step through the LEDs, from 7 to 0

for(index = 7; index >= 0; index--)

{

digitalWrite(ledPins[index], HIGH); // turn LED on

delay(delayTime); // pause to slow down

digitalWrite(ledPins[index], LOW); // turn LED off

}

}

/*

marquee()

This function will mimic "chase lights" like those around signs.

*/

void marquee()

{

int index;

int delayTime = 200; // milliseconds to pause between LEDs

// Make this smaller for faster switching

// Step through the first four LEDs

// (We'll light up one in the lower 4 and one in the upper 4)

for(index = 0; index <= 3; index++) // Step from 0 to 3

{

digitalWrite(ledPins[index], HIGH); // Turn a LED on

digitalWrite(ledPins[index+4], HIGH); // Skip four, and turn that LED on

delay(delayTime); // Pause to slow down the sequence

digitalWrite(ledPins[index], LOW); // Turn the LED off

digitalWrite(ledPins[index+4], LOW); // Skip four, and turn that LED off

}

}

/*

randomLED()

This function will turn on random LEDs. Can you modify it so it

also lights them for random times?

*/

void randomLED()

{

int index;

int delayTime;

// The random() function will return a semi-random number each

// time it is called. See http://arduino.cc/en/Reference/Random

// for tips on how to make random() even more random.

index = random(8); // pick a random number between 0 and 7

delayTime = 100;

digitalWrite(ledPins[index], HIGH); // turn LED on

delay(delayTime); // pause to slow down

digitalWrite(ledPins[index], LOW); // turn LED off

}

Code To Note

int ledPins[] = {2,3,4,5,6,7,8,9};

When you have to manage a lot of variables, an “array” is a handy way to group them together. Here we’re creating an array of integers, called ledPins, with eight elements.

digitalWrite(ledPins[0], HIGH);

You refer to the elements in an array by their position. The first element is at position 0, the second is at position 1, etc. You refer to an element using “ledPins[x]” where x is the position. Here we’re making digital pin 2 HIGH, since the array element at position 0 is “2”.

index = random(8);

Computers like to do the same things each time they run. But sometimes you want to do things randomly, such as simulating the roll of a dice. The random() function is a great way to do this.

See http://arduino.cc/en/reference/random for more information.

What You Should See

This is similar to circuit number one, but instead of one LED, you should see all the LEDs blink. If they aren’t, make sure you have assembled the circuit correctly and verified and uploaded the code to your board, or see the troubleshooting section.

Real World Application

Scrolling marquee displays are generally used to spread short segments of important information. They are built out of many LEDs.

Troubleshooting

Some LEDs Fail to Light

It is easy to insert an LED backwards. Check the LEDs that aren’t working and ensure they are in the correct orientation.

Operating out of sequence

With eight wires it’s easy to cross a couple. Double check that the first LED is plugged into pin 2 and each pin thereafter.

Starting Fresh

It’s easy to accidentally misplace a wire without noticing. Pulling everything out and starting with a fresh slate is often easier than trying to track down the problem.

Introduction

Up until now, we’ve focused mostly on outputs. Now we’re going to go to the other end of spectrum and play around with inputs. In experiment 2, we used an analog input to read the potentiometer. In this circuit, we’ll be reading in one of the most common and simple inputs – a push button – by using a digital input. The way a push button works with your RedBoard or Arduino Uno R3 is that when the button is pushed, the voltage goes LOW. You RedBoard or Arduino Uno R3 reads this and reacts accordingly.

In this circuit, you will also use a pull-up resistor, which keeps the voltage HIGH when you’re not pressing the button.

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x RedBoard or Arduino Uno

- 1x LED

- 1x 330Ω Resistor

- 7x Jumper Wires

- 2x Push Buttons

- 2x 10k Resistors

Didn’t get the SIK?

If you are following through this experiment and didn’t get the SIK, we suggest using these parts:

![Breadboard - Self-Adhesive (White)]()

In stock

PRT-12002

**Description**: This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a t…

4.95

![Tactile Button Assortment]()

In stock

COM-10302

These tactile buttons are great for all sorts of projects. This assortment comes with 2 of each of 6 different colors for a t…

4.95

![Jumper Wires Standard 7" M/M Pack of 30]()

In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

4.95

![Resistor 330 Ohm 1/6 Watt PTH - 20 pack]()

In stock

COM-11507

1/6 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 330Ohm resistors make excellent…

0.95

![LED - Assorted (20 pack)]()

In stock

COM-12062