Introduction

The SparkFun Inventor’s Kit for Intel® Edison, otherwise known as the Edison SIK, introduces the Edison as a powerful Internet of Things (IoT) platform. The experiments contained within these pages will guide you through programming the Edison using JavaScript and controlling various electronics. Whether you are new to electronics and JavaScript or are looking to take your skills to the next level (to the “cloud!”), this kit is a great starting point.

Set Aside Some Time - Please allow yourself ample time to complete each experiment. You may not get through all the experiments in one sitting. Each experiment also contains suggestions on project ideas and taking the examples to the next level. We suggest that you challenge yourself and try some of them!

Included Materials

Here is a complete list of all the parts included in the Edison SIK.

![Inventor's Kit for Intel Edison components]()

The SparkFun Inventor’s Kit for Intel® Edison includes the following:

If, at any time, you are unsure which part a particular experiment is asking for, reference this section.

Suggested Reading

The following links may help guide you in your journey through the Edison SIK.

Each experiment will also have a Suggested Reading section to aid you in understanding the components and concepts used in that particular experiment.

NOTE: If you would like to see all of the example code in one place, it can be found on GitHub! Just click the button below to be taken to the GitHub repository and click the link to Download ZIP.

Edison SIK Example Code

Using the Kit

Before exploring the experiments, there are a few items to cover first. If you have completed one of our other Inventor’s Kits before, you should already be familiar with most of the concepts in this section. If this is your first Inventor’s Kit, please read this part carefully to ensure the best possible SIK experience.

Intel® Edison

The Intel® Edison acts as the brain for the kit. The Edison sports a dual-core, 500 MHz Atom Z34XX processor, 1 GB of RAM, and 4 GB of onboard flash storage. It has built-in WiFi and Bluetooth. Those are some impressive statistics, but what does that mean? Well, the Edison is a complete computer in a tiny package. It is even capable of running a Linux operating system! To learn more about the Edison, visit the Edison Getting Started Guide.

Edison Getting Started Guide

An introduction to the Intel® Edison. Then a quick walk through on interacting with the console, connecting to WiFi, and doing...stuff.

Breadboard

Solderless breadboards are the go-to prototyping tool for those getting started with electronics. If you have never used a breadboard before, we recommend reading through our How to Use a Breadboard tutorial before starting with the experiments.

How to Use a Breadboard

Welcome to the wonderful world of breadboards. Here we will learn what a breadboard is and how to use one to build your very first circuit.

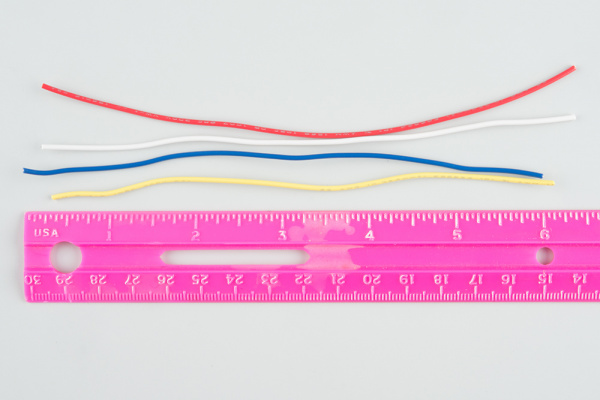

Jumper Wires

This kit includes thirty 7" long jumper wires terminated as male to male. You can use these to connect terminal strips on a solderless breadboard or connect them to the header on the ADC Block.

![M/M jumper wires]()

Screwdriver

We’ve included a pocket screwdriver to aid you in any mechanical portions of this guide. Note that the screwdriver bit can be pulled out from the plastic handle. The bit can be turned around and inserted back into the handle if you need to choose between a Phillips or a flathead driver.

![SparkFun Mini Screwdriver]()

USB Ports

The Edison Base Block has 2 USB ports.

![USB ports on the Edison Base Block]()

- Console - This port is attached to an FTDI chip that converts USB signals to serial. This allows you to connect to a serial terminal on the Edison. Only the USB microB cable (the 6-foot cable) can fit into this port.

- OTG - OTG stands for On-the-Go, and it means that the Edison can act as a USB host or a USB device. You may plug either the USB microB cable (for using the Edison as a USB device) or the 4-inch USB microA cable (for using the Edison as a USB host) into this port.

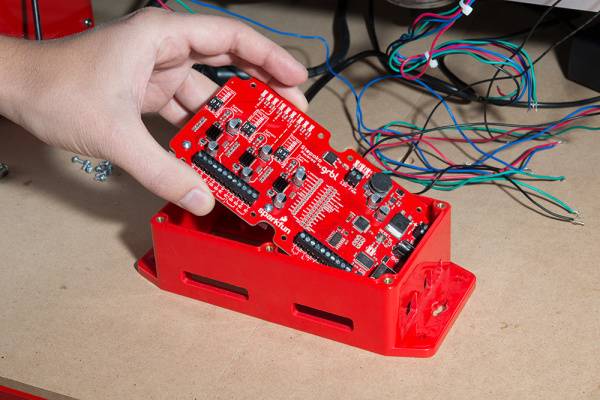

Building the Block Stack

Before we can use the Edison in any of our circuits, we must first attach it to the Blocks in the kit. The Blocks stack in a particular order to work best with the kit.

Parts needed

You will need the following parts:

- 1x Intel® Edison

- 1x ADC Block

- 1x Base Block

- 1x GPIO Block

- 1x Edison Hardware Pack

Don't have the kit? No worries! You can still have fun and follow along with these experiments. We suggest using the parts below:

In stock

DEV-13045

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

9In stock

DEV-13038

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

3In stock

DEV-13024

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

15In stock

DEV-13327

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

In stock

COM-13187

This is a Hardware Pack for the Intel® Edison, with this set you will be provided with increased mechanical strength for sta…

7Attach the Edison to the ADC Block

Open the Edison Hardware Pack. Put 2 screws through the mounting holes in the Edison, such that the screws' heads are facing up (we’ll call “up” the surface of the Edison with the “Intel® Edison” logo).

![Screws through the Edison]()

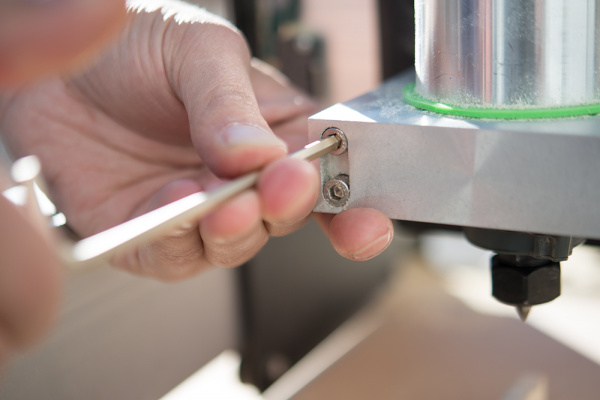

Attach 2 standoffs to the screws sticking out the bottom of the Edison. Use the pocket screwdriver to carefully tighten the screws.

![Standoffs on the Edison]()

Snap the Edison into the socket on the ADC Block. Make sure that the bottoms of the standoffs are protruding through the mounting holes on the ADC Block.

![Edison and ADC Block]()

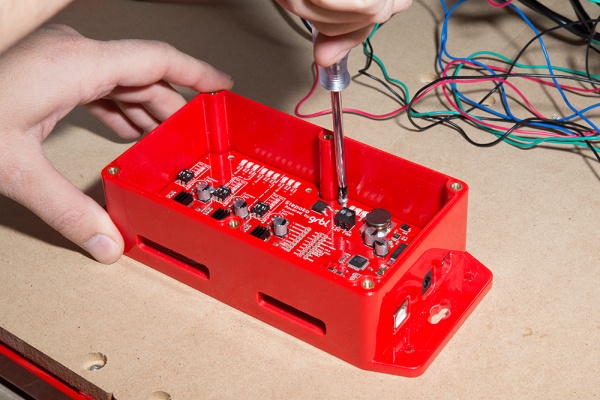

Screw 2 nuts onto the standoffs, securing the Edison to the ADC Block. You can use the pocket screwdriver to hold the screws in place while you tighten the nuts. Go slowly! The nuts can be tightened by hand, but it requires some finesse as they are quite small.

![Nuts tightened on ADC Block]()

Attach the Base Block

Put 4 screws through the mounting holes on the corners of the ADC Block, such that the screws' heads are facing up (the same direction as the screws securing the Edison).

![Screws in the ADC Block]()

Attach 4 standoffs to those screws. Use the pocket screwdriver to carefully tighten the screws.

![Standoffs on the ADC Block]()

Snap the ADC Block (which has the Edison on top) into the socket on the Base Block. Make sure that the bottoms of the standoffs are protruding through the mounting holes on the Base Block.

![Base Block attached to stack]()

Attach the GPIO Block

Attach 4 standoffs to the bottoms of the standoffs that are protruding from the mounting holes on the Base Block.

![Standoffs attached to Base Block]()

Snap the Base Block (which has the ADC and Edison mounted on top) into the socket on the GPIO Block. Make sure that the bottoms of the standoffs are protruding through the mounting holes on the GPIO Block.

![GPIO Block attached to stack]()

Screw the remaining 4 nuts onto the standoffs, securing the entire stack of Blocks together.

![Nuts tightened on GPIO Block]()

Flip the entire stack around, and make sure it is in the following order:

- Edison

- ADC Block

- Base Block

- GPIO Block

![Full Edison Block stack]()

Installing the Intel® XDK IoT Edition

The Intel® XDK is Intel’s integrated development environment (IDE) for creating, testing, and deploying mobile apps. We will be using the XDK IoT Edition, which was specifically designed to help users develop Node.js and HTML5 applications for the Intel® Edison and Intel® Galileo.

![XDK Project view]()

NOTE: You will need to sign up for an

Intel® Developer Zone Account to use the XDK. If you would prefer not to use the XDK, you can program Node.js applications directly in the Edison (you will just miss out on cool things like code completion, and you might have to skip some of the phone app exercises.). Visit

Appendix B: Programming Without the XDK to learn how.

Download the Installer

The easiest way to install the XDK is to use the Intel® Edison Integrated Installer. This contains the XDK, drivers, and Flashing Tool (to update the Edison Firmware). Follow the link below and download the Installer for your operating system:

Intel® Edison Integrated Installer

WARNING: Make sure you do not have any Edisons plugged in to your computer for the installation!

Windows

Run the Installer that you just downloaded. You will see a splash screen as it unzips and prepares to install.

![XDK Splash Screen]()

Once you get the “Welcome to Intel® Edison” screen, click Next. You might get a screen telling you to install “Java SE Runtime.” Just ignore it, as we will not be developing in Java (JavaScript is not the same as Java!).

![Ignore the warning about installing Java]()

Click Next to continue the installation process. The ubiquitous License Agreement will pop up. Feel free to read it (or not).

![Eek! A EULA!]()

Select I accept the terms of the license and click Next. You will then be presented with options to install. Deselect Update Image (we will do that separately in the next section), deselect Arduino Software, and select Intel® XDK IoT Edition.

![We want to install the XDK IoT Edition]()

Click Next. On the next screen, make sure that you have enough space to install the programs. Leave the installation directory as default.

![Installation directory for the XDK]()

Click Next, verify that the installation summary looks correct, and click Next again. Wait a few minutes while the installation completes.

NOTE: The installation process might attempt to install other drivers and programs. Accept all the defaults and choose to install additional programs. This is especially true on Windows where the Installer will want to install drivers, which are necessary for deploying code to the Edison. This includes things like "FTDI Drivers" and the "Phone Flash Tool Lite." Also, if the installation seems to have frozen, check for new windows that may have been opened.

Once the installation process is done, you will see a “Complete” window.

![XDK installation is complete]()

Click Finish. If the Intel® Phone Flash Tool Lite opened during the process, you can leave it open if you wish (we will use it in the next section).

The installer or drivers may ask you to restart your computer.

OS X

The OS X Installer link will download a .tar.gz file. Double-click on that file to extract it. Double-click on the extracted file to run the installer.

![Downloaded XDK IoT Edition]()

Follow the prompts, clicking Next to advance to the next screen. Accept the End User License Agreement when prompted. On the Installation summary screen, click Customize Installation.

![Customize XDK IoT Edition install]()

Keep the destination folder (/Applications) at the default and click Next. You will be presented with the option to select the components to install. Deselect Arduino Software, and select Intel® XDK IoT Edition.

![Select the right options for the Edison installer]()

Click Next and deselect Update firmware image (we will do that manually in the next section).

![Do not update the Edison firmware now]()

Click Next and then Install. Wait while the installer downloads. You will then be prompted to install the Phone Flash Tool Lite.

![Install the Phone Flash Tool Lite]()

Click Continue and follow the prompts. Once the XDK has finished installing, the XDK can be found under Applications.

![The XDK can be found in Applications in OS X]()

Linux

Download the installer, double-click on the file to extract it, and navigate into the directory that it creates.

![Install script for XDK]()

Double-click on the install.sh script (select Run if prompted) to begin the installer.

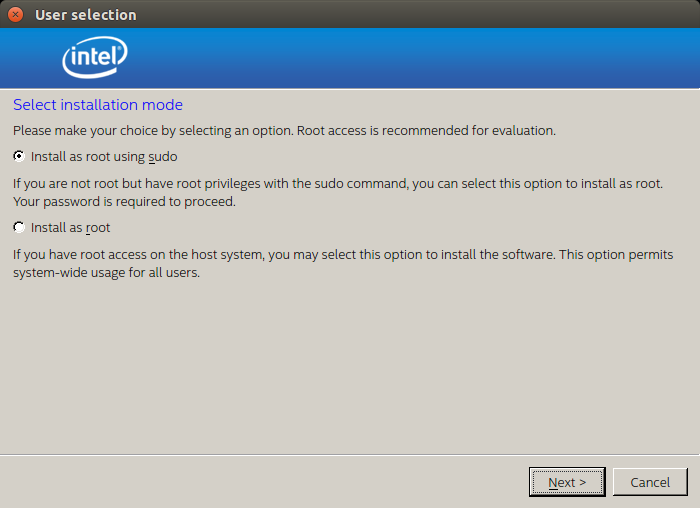

![Install as root for XDK]()

If you want the XDK to be available to all users, select Install as root. Otherwise, select Install as root using sudo. Accept the terms of the End User License Agreement, and accept all defaults until you are presented with a summary screen.

![Customize installation on XDK]()

Click Customize installation, and accept the default installation directory on the next screen. You will be presented with some installation options.

![Select to install the XDK]()

Deselect Arduino Software, and select Intel® XDK IoT Edition. Click Next.

![Do not update firmware for the Edison]()

Deselect Update firmware image, and click Next. There is a chance that your system might be missing some dependencies (e.g. “Dependencies not resolved”).

![Phone Flash Tool Lite dependencies not resolved]()

If so, you will need to open a command prompt and install them using apt-get. For example, I am missing fping, gdebi, and p7zip-full. So, I entered the following commands:

sudo apt-get update

sudo apt-get install fping gdebi p7zip-full

Wait for those to finish installing, and click Re-check on the missing dependencies screen. You should be good to install.

![XDK Installer summary]()

Click Install and wait for the installation to complete (clicking to accept any defaults on prompts). The XDK IoT Edition can be found in /usr/share/applications when the installation is complete.

![XDK in installation directory]()

NOTE: If the Phone Flash Tool Lite failed to install, you can install it manually by following

these instructions.

Updating the Edison Firmware

Most Edisons will ship with an older firmware (perhaps many months out of date). They will either contain bugs or simply not work with the latest version of the XDK IoT Edition. To remedy this problem, we highly recommend updating the firmware on the Edison.

To begin, download the latest firmware. Navigate to Intel’s site using the link below and click to download the latest release of the Yocto complete image.

Intel® Downloads Page

![Intel downloads page]()

In this example, the latest firmware is “Release 2.1 Yocto complete image”

Once the download is complete, locate the file on your computer, and unzip it.

Updating the Firmware with the Phone Flash Tool

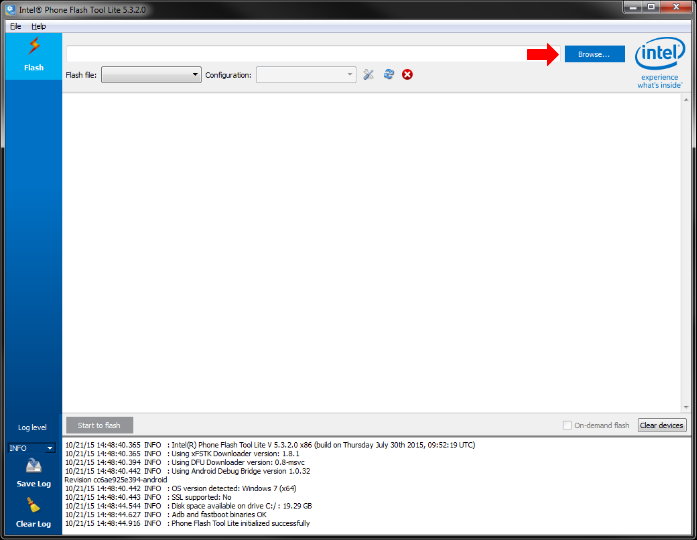

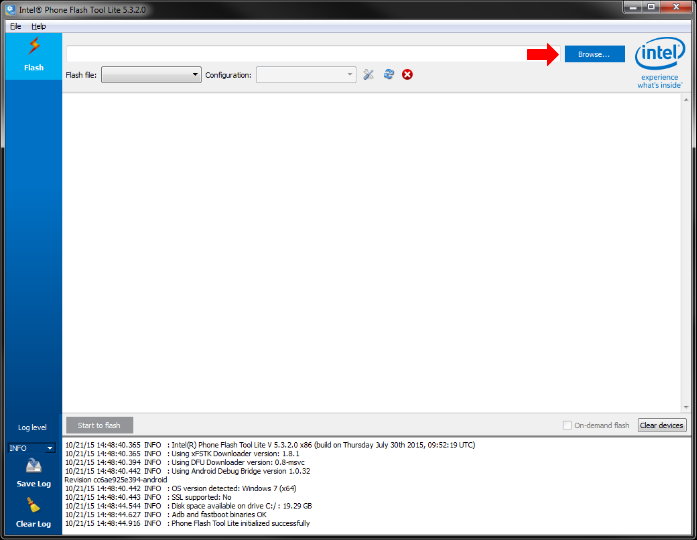

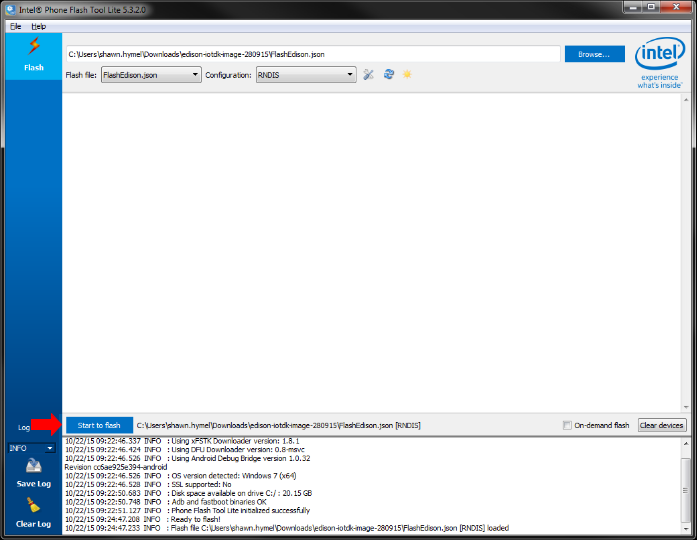

If it is not open already, open the Intel® Phone Flash Tool Lite program that we installed in the last section.

[]()

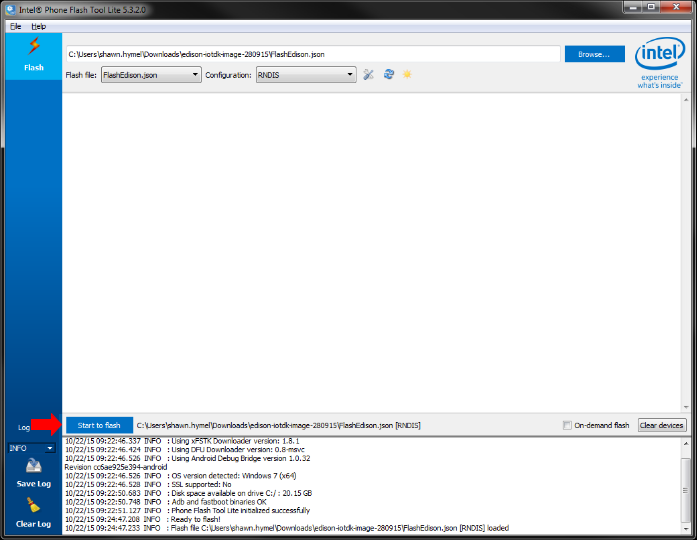

Click Browse, and navigate to the unzipped Edison firmware directory. Locate the FlashEdison.json file, and click Open. This will load the firmware into the Phone Flash Tool.

[]()

Click the Start to flash button. The Phone Flash Tool will tell you to plug in your Edison. Plug the USB micro cable into the OTG Port on the Base Block, and plug the other end into an open USB port of your computer.

![Edison Base Block OTG USB port]()

The Phone Flash Tool should begin to flash the Edison with a new firmware image.

![Flashing the Edison's firmware]()

The updating process can take anywhere from 5-10 minutes. We recommend

making a sandwich and catching up on web comics in that time. The Edison will restart once or twice after the installation is complete. Wait at least

2 more minutes after the update to allow the Edison to finish rebooting. Do not unplug the Edison in that time!

That’s it! You should see a “Flash success” message in the Phone Flash Tool. If this worked, you can close the Phone Flash Tool Lite, and move on to the next section.

![Successful firmware update in the Edison]()

NOTE: If the Edison failed to flash, try the process again from the beginning. Close the Flash Tool Lite and unplug the Edison. Start the Flash Tool Lite again. This might take a few tries. If that still does not work, try the

Manual Firmware Update method.

Using the XDK

If you have used other Integrated Development Environments before, the Intel® XDK IoT Edition might look familiar. If not, no worries! We will walk you through how to use the XDK (don’t worry, it’s not very complicated). If you would like to take a look at Intel’s official documentation on the XDK, it can be found here:

Intel® XDK IoT Edition Guide

Starting the XDK for the First Time

Start the Intel® XDK IoT Edition program, and you should be presented with a login screen.

![XDK login or account creation screen]()

Click Sign Up if you do not already have an Intel Developer Zone Account, and follow the on-screen instructions to create a new account. You will need to accept another Terms and Conditions statement.

The Welcome Screen

Once you have created an account (or not), you will be presented with the welcome screen. In this screen, you can choose an existing project to work on or create a new one.

![XDK welcome screen annotated]()

Click the image above for a larger view.

Creating a Project

To familiarize ourselves with the XDK IDE, we will create a blank project. Click on Templates under the Internet of Things Embedded Application tab. You will see a number of different templates appear that will help you get started with your IoT program. Select the Blank Template.

![Selecting a template in the XDK]()

Click Continue, and you will be presented with a pop-up window to name your project. You can name it anything you want, as we are just using it to explore the IDE right now. To keep all my XDK projects together, I like to use the prefix “XDK_”. I will use “XDK_Blank” for this example.

![Creating a new project in the XDK]()

Click Create. The project screen will greet you with a mostly empty JavaScript file.

NOTE: You might be asked to take a quick tour of the XDK when you first create a project. Feel free to do it or skip it.

The Project Screen

![XDK project screen annotated]()

We use the XDK to write code. There are several tools available that help us do that: code examples, syntax completion, a debugging interface, and so on. Once we have finished writing code, we click the Upload button to send that code to the Edison. The Run button then tells the Edison to run the code we just sent to it.

By default, the Yocto image on the Edison contains an “XDK Daemon.” A daemon is a computer program that runs in the background (at least according to Wikipedia). The XDK Daemon begins running as soon as the Edison boots and listens for a connection from a host computer (i.e. one running the XDK IoT Edition). It knows how to receive and store new code, and it will accept commands from the host computer to run, stop, and debug that program.

NOTE: You can click the word PROJECTS at the top-left of the window to return to the navigation screen.

Connecting to WiFi

We will want connect our Edison to a local WiFi network if we want to program it using the XDK or complete some of the experiments that require Internet access.

NOTE: Alternatively, you can use a USB Network to program the Edison from the XDK. Refer to

Appendix C to see how to use a USB network with your Edison. Note that without a WiFi connection, you will not be able to complete the exercises that require Internet access.

Connecting Over Serial

Unplug the USB cable from the OTG port on the Base Block, and plug it into Console port.

![Edison Base Block Console USB port]()

If it is not already open, start the XDK, and create a blank project (like we did in Using the XDK). Click on the Serial Terminal tab.

![Serial terminal in XDK]()

At the very bottom, click the drop-down list for Port and select the Edison device. This will change depending on the operating system. For example, it might be /dev/tty.usbserial-A402IXA0 in OS X, /dev/ttyUSB0 in Linux, or COM78 in Windows. Note that in Windows, you want COMxx[FTDI], not the Standard Serial Port option.

![Selecting a serial terminal in XDK]()

Make sure that the Baud Rate is 115200, Data Bits is 8, Stop Bits is 1, and Parity is “none.” Click Connect, and you should see the Edison’s terminal login appear.

![Connecting to Edison's serial terminal with the XDK]()

Getting on the Internet

Click in the Serial Terminal window and log in to the Edison:

Username: root

Hit ‘enter’ (there is no password). You should be presented with a root command prompt.

![Logging in as root]()

Enter configure_edison --setup. You will be walked through a series of steps. The first will ask you to create a password.

![Configure the Edison]()

We definitely recommend you set a password! It can be anything you want, so long as you can remember it. If you don’t set a password, evil hackers might be able to control your lights from their car. Or read your emails. That would be bad.

Press ‘enter’ and enter your password again. On the next screen, you will be asked to rename the Edison. You can give it a unique name or just press ‘enter’ to keep the default name. I shall call mine squishy.

![My Edison called squishy]()

The Edison will ask you to confirm the name. Type ‘y’ and press ‘enter’. You will then be asked to set up WiFi. Enter ‘y’ again.

![Yes, we want to set up WiFi on the Edison]()

Wait while the Edison scans for networks. You will then be presented with a list of available networks.

![Available WiFi access points]()

Type the number of the network you would like to join and press ‘enter’. Enter ‘y’ to accept the network, and enter the password for that network.

![Enter the password for the WiFi network]()

The Edison should automatically connect to the network. Enter ping 8.8.8.8 to try pinging one of Google’s Public DNS servers.

![Successful pings from the Edison]()

You should see a few responses in the form of “bytes received from 8.8.8.8.” Press ‘ctrl+c’ to stop the pinging. You can get the IP address of the Edison by entering ifconfig.

![Edison ifconfig]()

Under the wlan0 entry, make a note of the inet addr. In my case, it is 10.8.0.171. You can use this to connect to your Edison manually from the IoT Device drop-down menu if, for example, the Bonjour service is not running (if you ran the Installer and accepted all the defaults, Bonjour should have been installed).

NOTE: If you restart your Edison, it should auto-connect to the last network you set. However, you might not get the same IP address. We recommend connecting over serial and typing

ifconfig to see that address if you need it. You can also give your Edison a static IP address, if you so desire. See

here to lear more about networking in Linux.

Experiment 1: Hello, World!

Introduction

We realize that starting with “Hello, World!” is a cliché in the programming world, but it really is the perfect starting place with the XDK and Edison. We spent quite some time installing the XDK, flashing new firmware, and configuring the Edison. We can test all these things with one line of code!

Parts Needed

You will need the Edison and Block stack that we constructed in Building the Block Stack section.

Suggested Reading

- JavaScript Syntax– Whether you are new to JavaScript or a seasoned developer, you might want to look at how JavaScript statements are structured. For example, JavaScript uses semicolons.

- Oject-Oriented Programming (OOP)– JavaScript relies on objects to get work done. Reading about the history of OOP might be enlightening and entertaining.

Concepts

A Very Light Introduction to Objects

In JavaScript almost everything is an object. What is an object? In the real world, an object is just another word for a thing. A dog, for example, is a type of object.

![A dog object]()

A dog has properties, such as a breed, a fur color, a name, and so on. Dogs can also do things, like bark, sleep, play, etc.

OK, so how does this translate to the programming world? In most object-oriented languages, an object is a collection of data (bytes stored somewhere on the computer) that has been grouped together and wrapped up in a way that makes for easy access. If we wanted to make a JavaScript version of our dog, we might write something like:

language:javascript

var dog = {

name: "Roland",

color: "fawn",

bark: function() {

console.log("woof");

}

};

In this example, we created a variable (as noted by the keyword var) called dog. A variable is a way to store things. In this case, we are storing our object (a collection of properties) in a storage container called dog.

All of the properties for this object are defined between the outside set of curly braces {}. We create a property called name and assign it the value "Roland". If we wanted to get the name of our dog object, we could access that property with:

language:javascript

dog.name;

Calling dog.name results in “Roland”.

In addition to our name and color properties, we also defined a function as a property. If we called

language:javascript

dog.bark();

the dog would do something. Functions are actions! They cause the object to do something. The parentheses () after dog.bark let us know that it is a function. They can also be used to pass parameters to the function, which we will see in a minute. Because bark() is a function inside an object, it is known as a method (functions not part of objects are just called functions).

If we dig into the bark() method, we see that it contains console.log("woof");. console is a special object that is known by most implementations of JavaScript (i.e. it is an object that always exists when we run the program). .log() is a method of the console object. By calling console.log() we can print something to the screen (assuming we have access to some kind of text output console).

"woof" is a parameter, which is a value that is passed to a function. In this case, “woof” is a string (as noted by the double quotes), which is a collection of characters. The function then, ideally, uses that value in its own code. In this case, console.log("woof") prints the word woof to the screen.

Ultimately, calling dog.bark(); prints woof to the screen.

This might be a lot to take in, but never fear! We will revisit these concepts over the course of these experiments. For now, know that objects are containers for properties and methods. We will be using the special console object to output text to the screen.

Hardware Hookup

We won’t need any new hardware. Just connect the USB cable from your computer to the Console Port on the stack you made in Building the Block Stack.

![Edison Base Block USB Console port]()

The Code

Open the XDK, and create a new project. Use the Blank Template, and give it an appropriate name (we’ll call this one “XDK_Hello”). If you need a refresher on creating projects, see Using the XDK.

NOTE: The Edison is remotely programmable, but your host computer must be on the same network (

subnet) as the Edison if you want to use the XDK (i.e. both your computer and Edison are connected to the same WiFi network). Alternatively, you can use a USB cable to create a

USB network between your computer and the Edison.

The first thing we want to do is connect to our Edison. To do that, click the drop-down list by IoT Device, and select your Edison device.

![Select Edison device]()

NOTE: If the Edison device does not appear automatically (e.g. you don't have Bonjour installed), then you can select

Add Manual Connection and fill in the IP address of the Edison you got from

Connecting to WiFi.

You should be presented with a connection screen. Type in the password you set for the Edison in the Password field.

![IoT Device connection screen]()

Click Connect. If you get presented with a message claiming that the “Intel XDK Daemon is old” or that you need to sync clocks with the Edison, choose to Update the Dameon or Sync as appropriate and follow the prompts.

![What do you mean my XDK daemon is old?]()

Once you have updated, synced, and connected, you should see a message in the console of the Intel XDK IoT tab.

![XDK connected to Edison]()

In main.js, add the following line:

language:javascript

console.log("Hello, World!");

Find and click the Upload button.

![Upload code to the Edison]()

If you are presented with a message exclaiming that you have “Modified Project Files,” click Save and Proceed.

In the console, you should see the message “Upload Complete.” Press the Run button.

![Run code on the Edison]()

What You Should See

The phrase “Hello, World!” should appear in the console.

![Edison Hello World]()

If you see this, feel free to celebrate. We’ll wait a moment while you do that.

Why is this simple phrase monumental? Well, it means all our preparing and configuring worked! We wrote a simple program, sent it to the Edison, and had the Edison run it. Cool.

Code to Note

The Console Object

console is a special object that has been pre-defined elsewhere in our JavaScript environment. It outputs to standard output, which is a text display device (real or virtual) for most computer systems.

The Edison relies on Node.js to run JavaScript programs. More information about the console object can be found in the official documentation.

Methods

We mentioned methods briefly in our introduction to objects. In this exercise, we used the .log() method, which takes input in the form of a string (a parameter) and displays it on a new line in the console. The Node.js documentation contains a section on .log().

Comments

There are different ways to make comments in your code. Comments are a great way to quickly describe what is happening in your code.

// This is a comment - anything on a line after "//" is ignored by the computer.

/* This is also a comment - this one can be multi-line, but it

must start and end with these characters */

Troubleshooting

- The Edison won’t connect– This is possible if the Edison is not powered or configured properly. See the “Edison won’t connect” section in the Appendix A: Troubleshooting.

- Code will not upload– Make sure the Edison is on the same network as your computer and you have selected your Edison from the IoT Device drop-down menu in the XDK.

- Nothing prints on the console– Make sure that the Edison is connected. Additionally, if you see any errors on the console, read them carefully, as they will often tell where to look in your code (for example, you might have forgotten the quotation marks around “Hello, World!”).

- Nothing works!– Don’t worry! We have an awesome tech support staff to help you out if there is something wrong. Please contact our tech support team.

Going Further

Now that you see how to connect your Edison to the XDK, upload code, and run a program, we will move on to more advanced topics including connecting other pieces of hardware to the Edison Block stack. After each experiment, we will give you a few challenges to try on your own as well as some suggested reading.

Challenges

- Remember the description of the dog object in the beginning of this chapter? Copy the definition of the dog object (the snippet of JavaScript code) into the XDK. Write some code that has the dog bark (e.g. you will see woof appear in the console). Hint: you will need to use

console.log(). - Using the same dog object example, print out the dog’s name and color to the console.

Digging Deeper

Introduction

In the previous exercise, we tested the connection to the Edison and showed that we could upload code. Now, we can move on to more interesting circuits and examples. In this section, we introduce the humble push button. We connect it to one of the Edison’s general-purpose input/output (GPIO) pins and write some code that does something whenever the button is pushed.

This experiment has 2 parts. Both parts use the same hardware, but each has its own code. We recommend you try them both to get an understanding of the different ways to use button pushes.

Parts Needed

In addition to the Edison and Block Stack, you will need the following parts:

- 1x Breadboard

- 1x Push Button

- 1x 1kΩ Resistor

- 4x Jumper Wires

![1k resistor]()

The 1kΩ resistor has the color bands brown, black, red, gold

Using the Edison by itself or don't have the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

COM-10969

Resistors are a good thing, in fact, they're actually crucial in a lot of circuit designs. The only problem seems to be that …

65In stock

DEV-13045

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

9In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

17In stock

PRT-00116

A row of headers - break to fit. 40 pins that can be cut to any size. Used with custom PCBs or general custom headers.

**Fea…

18In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

18In stock

PRT-00115

Single row of 40-holes, female header. Can be cut to size with a pair of wire-cutters. Standard .1" spacing. We use them exte…

5In stock

DEV-13038

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

3In stock

DEV-13024

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

15In stock

COM-10302

These tactile buttons are great for all sorts of projects. This assortment comes with 2 of each of 6 different colors for a t…

Suggested Reading

Concepts

Functions

We mentioned briefly in the last section that functions are pieces of code that do things. To make this more clear, a function is a block of code created to perform a particular task. Functions are useful because they can be written once and called many, many times from other parts of code (we call this code reuse).

In our two code examples below, we will write our own functions and then call them. In JavaScript, functions looks like this:

language:JavaScript

function doSomething( /* parameters */ ) {

/* Things happen here */

}

We know it is a function because we used the function keyword. Thanks for making this explicit, JavaScript. We can also have 0 to any number of parameters in our function. Parameters are variables that are used to store pieces of information passed to the function. For example:

language:JavaScript

function saySomething(thing) {

console.log(thing);

}

saySomething("Hi");

We first created a function that outputs something to the console. In this case, the function accepts the parameter thing, which becomes a variable. We can access the contents of that variable by writing thing.

Then, we call our function by writing saySomething(). In between the parentheses, we wrote the string "Hi". This string is passed to the saySomething() function as a parameter and assigned to the variable thing. We then print the contents of thing (“Hi” in this example) to the console.

If we wanted to print something else, we could write saySomething("Something else");. And that’s a simple form of code reuse!

Libraries

![A particularly grand library]()

OK, not THAT kind of library

Libraries are pieces of code that have been packaged up for easy reuse. Often, they are written by someone else (or a group of people).

Node.js (the runtime environment that runs our code on the Edison) uses modules, which are very similar to libraries. Modules are just other pieces of code that we can reuse in our code. In these experiments, we rely heavily on MRAA, which is a library (and subsequent Node.js module) created by Intel and allows us to easily communicate with the hardware pins on the Edison.

We can import the MRAA module with the line

language:JavaScript

var mraa = require('mraa');

With that, all the objects, variables, and functions in the MRAA module are loaded into the variable mraa. We can access those objects, variables, and functions by calling mraa. For example, mraa.Gpio() creates a new GPIO pin that we can access.

The Pull-Up Resistor

We can use a resistor to set a default state of a pin on a microcontroller (or, in this case, the Edison). The pull-up resistor, specifically, sets the state of the pin to a voltage (VCC in the diagram below). For our circuit, we will be using 3.3V as the high voltage. Low will be ground (GND or 0V).

![Example of a pull-up resistor]()

When the switch (or button) is open (as in the diagram), the input pin is VCC. Because little or no current flows through R1, the voltage at the pin is the same (or very nearly the same) as VCC. We will say that the pin is in the “high state” or “logic ‘1’”.

When the switch (or button) is closed, the input pin is the same voltage as GND (0V). The switch creates a short circuit to GND, which causes some current to flow from VCC, through R1, to GND. However, because of the short circuit, the input pin has the same voltage as GND. We will say that the pin is in the “low state” or “logic ‘0’”.

Hardware Hookup

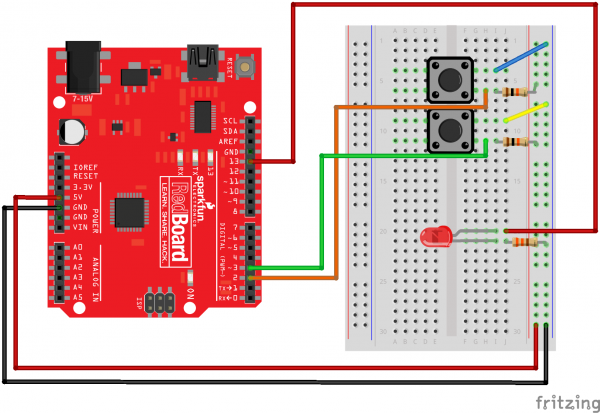

Your kit comes with a bunch of different color push button. All push buttons behave the same, so go ahead and use your favorite color! Follow the Fritzing diagram below.

NOTE: We are using GP14 on the GPIO Block, which connects to GPIO pin 14 on the Edison's 70-pin Hirose connector (see

here for the pinout). However, the MRAA library uses a different numbering scheme. GP14 is actually pin 36 according to MRAA. The GPIO pin to MRAA pin mapping can be found in

Appendix E: MRAA Pin Table. Find the GPIO number you are using on the left-most column and lookup the MRAA number on the next column. The MRAA number is what you will use in software.

Fritzing Diagram

![Edison SIK button Fritzing]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Tips

The leads across each other on the push buttons are always connected to each other. The leads on the same side are only connected when button is pressed.

![Push button connections]()

Part 1: Polling

The Code

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 2 - Part 1: Pushing Some Buttons

* This sketch was written by SparkFun Electronics

* October 27, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* This is a simple example program that displays the state of a button

* to the console.

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the MRAA module

var mraa = require('mraa');

// Set up a digital input/output on MRAA pin 36 (GP14)

var buttonPin = new mraa.Gpio(36);

// Set that pin as a digital input (read)

buttonPin.dir(mraa.DIR_IN);

// Call the periodicActivity function

periodicActivity();

// This function is called forever (due to the setTimeout() function)

function periodicActivity() {

// Read the value of the pin and print it to the screen

var val = buttonPin.read();

console.log('Button is ' + val);

// Wait for 250 ms and call this function again

setTimeout(periodicActivity, 250);

}

What You Should See

Try pushing the button.

![Button connected to the Edison]()

The console should start outputting “Button is 1”, which means that the pin connected to the button is currently in the high state (3.3V, logic ‘1’). When you push the button (hold it down for a second), the console should show “Button is 0”, which means that the pin is in the low state (0V, logic ‘0’).

![Polling button output]()

Code to Note

In JavaScript, functions are objects. Say what? I know it is weird to think about, but they are. The good news is that we can pass functions (like objects) as parameters to other functions. For example, we pass periodicActivity (a function) to setTimeout (another function), which causes periodicActivity to be called every 250 ms (in this example).

Additionally, note that we told MRAA that we want to use pin 36. Pin 36 is defined by MRAA and mapped to GP14, which is the pin definition according to the Edison hardware. Knowing which MRAA pin maps with which GP pin can be confusing, so we crated a nice table in Appendix E. The Edison pinout can be found here.

Part 2: Interrupt Service Routine

The Code

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 2 - Part 2: Interrupt Service Routine

* This sketch was written by SparkFun Electronics

* October 27, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* This is a simple example program that prints an incrementing number

* to the console every time a button is pushed.

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the MRAA module

var mraa = require('mraa');

// Set up digital input on MRAA pin 36 (GP14)

var buttonPin = new mraa.Gpio(36);

buttonPin.dir(mraa.DIR_IN);

// Global counter

var num = 0;

// Our interrupt service routine

function serviceRoutine() {

num++;

console.log("BOOP " + num);

}

// Assign the ISR function to the button push

buttonPin.isr(mraa.EDGE_FALLING, serviceRoutine);

// Do nothing while we wait for the ISR

periodicActivity();

function periodicActivity() {

setTimeout(periodicActivity, 1000);

}

What You Should See

You should not see anything when you first run the program. Press the button, and the word “BOOP” should appear along with a number. Press the button again, and that number should increment by 1.

![Boop]()

Code to Note

Interrupt service routines (ISRs) are important in the world of embedded electronics. It is very similar to JavaScript’s notion of event-driven programming. When a user or some other external force performs an action, the program responds. In this case, whenever a button was pushed, the serviceRoutine() function gets called.

As in the previous polling example, we use a function as a parameter. We pass the function serviceRoutine to the buttonPin.isr() function. We use mraa.EDGE_FALLING to declare that serviceRoutine should be called whenever the pin’s voltage goes from high (3.3V) to low (0V).

Troubleshooting

- The Edison won’t connect– This is possible if the Edison is not powered or configured properly. See the “Edison won’t connect” section in the Appendix A: Troubleshooting.

- Nothing happens when the button is pushed– Double-check the wiring. Often, a jumper wire is off by 1 hole!

Going Further

Challenges

- Add a second button so that when the first button is pushed, it prints “BOOP” to the console, and when the second button is pushed, it prints “BEEP” to the console.

- You might have noticed that pushing the button on the second example causes more than one “BOOP” to appear (if not, try pushing the button many times to see if you can get more than one “BOOP” to appear per button push). This is a phenomenon known as bouncing. Modify the Part 2 example to prevent this from happening (known as debouncing).

Digging Deeper

Experiment 3: Blinky

Introduction

Often, blinking an LED is the first step in testing or learning a new microcontroller: a veritable “Hello, World!” of embedded electronics. However, the GPIO Block requires that we introduce a new component, the transistor, into the mix. As a result, we saved the blinky example for the third experiment.

We will connect an LED to the Edison (using the GPIO Block and a transistor). With some JavaScript, we can control that LED by turning it on and off.

Parts Needed

In addition to the Edison and Block Stack, you will need the following parts:

- 1x Breadboard

- 1x RGB LED

- 1x NPN Transistor

- 1x 1kΩ Resistor

- 1x 100Ω Resistor

- 5x Jumper Wires

![100 Ohm resistor]()

The 100Ω resistor has the color bands brown, black, brown, gold

![1k resistor]()

The 1kΩ resistor has the color bands brown, black, red, gold

Using the Edison by itself or don't have the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

COM-10969

Resistors are a good thing, in fact, they're actually crucial in a lot of circuit designs. The only problem seems to be that …

65In stock

DEV-13045

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

9In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

17In stock

PRT-00116

A row of headers - break to fit. 40 pins that can be cut to any size. Used with custom PCBs or general custom headers.

**Fea…

18In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

18In stock

PRT-00115

Single row of 40-holes, female header. Can be cut to size with a pair of wire-cutters. Standard .1" spacing. We use them exte…

5In stock

DEV-13038

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

3In stock

DEV-13024

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

15In stock

COM-09264

Ever hear of a thing called RGB? Red, Green, Blue? How about an RGB LED? These 5mm units have four pins - Cathode is the long…

2In stock

COM-00521

These are very common, high quality BJT NPN transistors made by ST Micro.

**Datasheet: **[2N3904](http://www.sparkfun.com/da…

Suggested Reading

Concepts

The Transistor

The GPIO Block is not capable of sourcing more than a few milliamps, which is not enough to fully light up an LED. To do that, we will use a transistor. A transistor is a device that can be used to amplify or switch electrical current. We will be using a bipolar junction transistor (BJT), which allows current to flow through the collector and emitter pins whenever a (much smaller) current flows into the base pin.

In this experiment, we will connect the base of the BJT to GP12 on the GPIO Block. When the GP12 pin goes high (3.3V), this causes a little bit of current to flow from GP12 through the base, which turns the transistor on. This allows current to flow from the 3.3V supply (also on the GPIO Block), through the collector, and out the emitter. This current then flows through the 100Ω resistor and LED, turning the LED on.

![Transistor switch for LED]()

We can calculate the amount of current flowing through the LED, as we want to make sure it is not over 20mA, as per the RGB LED datasheet. To do that, we need to figure out what the voltage drop across the 100Ω resistor. Starting with 3.3V, we can determine that the voltage across the collector and emitter (Vce) is 0.2V (Vce(sat) in the datasheet) when the transistor is fully on. Again from the LED’s datasheet, we see that that typical drop across the red LED is 2V. As a result, the voltage drop across the resistor can be calculated:

![Calculating the voltage drop across the resistor]()

Knowing that the drop across the resistor is 1.1V, we can use Ohm’s Law (V = I x R) to calculate the current flowing through the resistor:

![Finding the current through the resistor]()

![Current through limiting resistor]()

How to Use Logic Like a Vulcan

One of the things that makes the Edison so useful is that it can make complex decisions based on the input it’s getting. For example, you could make a thermostat that turns on a heater if it gets too cold, or a fan if it gets too hot, and it could even water your plants if they get too dry. In order to make such decisions, JavaScript provides a set of logic operations that let you build complex “if” statements. They include:

| == | EQUIVALENCE | A == B is true if A and B are the SAME. |

|---|

| != | DIFFERENCE | A != B is true if A and B are NOT THE SAME. |

|---|

| && | AND | A && B is true if BOTH A and B are TRUE. |

|---|

| || | OR | A || B is true if A or B or BOTH are TRUE. |

|---|

| ! | NOT | !A is TRUE if A is FALSE.!A is FALSE if A is TRUE. |

|---|

You can combine these functions to build complex if() statements. For example:

language:c

if ((mode == heat) && ((temperature < threshold) || (override == true))) {

turnOnHeater();

}

…will turn on a heater if you’re in heating mode AND the temperature is low, OR if you turn on a manual override. Using these logic operators, you can program your Edison to make intelligent decisions and take control of the world around it!

In addition to the comparator ‘==’ and ‘!=’, JavaScript also has the strict comparators ‘===’ and ‘!==’ where the two values being compared need to be the same type (e.g. both a string). See this page to learn more about JavaScript comparators.

Hardware Hookup

Fritzing Diagram

![Red LED with Edison Fritzing]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Tips

RGB LED

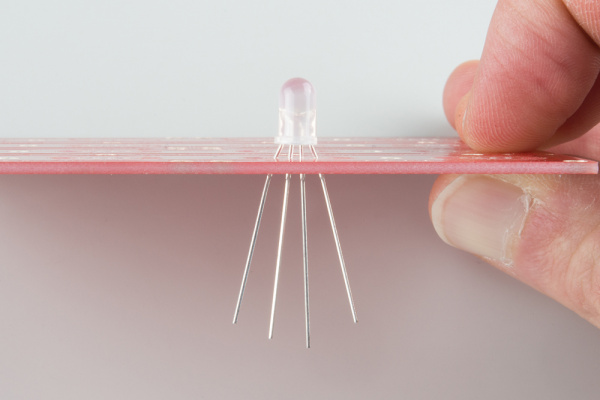

You can use a set of needle nose pliers to bend the LED’s leads and a pair of cutters to fit the LED in the breadboard. Note that there is a flat side on the plastic ring around the bottom of the LED. This denotes the side with the pin that controls the red color. See this tutorial to learn more about polarity.

![Common cathode RGB LED]()

NPN Transistor

WARNING: The 2N3904 transistor and TMP36 temperature sensor look very similar! Examine the flat face of the

TO-92 packages very carefully and find one that says

2N 3904.

Note that the flat face with the ‘N’ of the transistor in the Fritzing diagram matches up with the flat face (with the writing) of the physical part. With the flat edge facing you, the pins are as follows:

![Annotated 2N3904 NPN transistor]()

The Code

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 3: Blinky

* This sketch was written by SparkFun Electronics

* October 29, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* Blink an LED connected to GP12 (need a transistor if using the Base Block).

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the MRAA module

var mraa = require('mraa');

// Set up a digital output on MRAA pin 20 (GP12)

var ledPin = new mraa.Gpio(20);

ledPin.dir(mraa.DIR_OUT);

// Global variable to remember the LED state

var led = 0;

// Call this function over and over again

periodicActivity();

function periodicActivity() //

{

// Switch state of LED

if (led === 0) {

led = 1;

} else {

led = 0;

}

// Turn the LED on

ledPin.write(led);

// Wait for 500 ms and call this function again

setTimeout(periodicActivity, 500);

}

What You Should See

Upload and run the program. The LED should start flashing red.

![Edison flashing an LED]()

Code to Note

After we declare the ledPin as an output with mraa.DIR_OUT, we create the variable led that stores the state of the led (‘1’ for on and ‘0’ for off). Because this variable (and similarly mraa and ledPin) is declared outside of any object or function, they are considered global variables, which means they can be accessed by any function, object, etc. in the entire program. In most programming circles, using global variables is considered very bad practice. However, we rely on them in most of our examples because:

- JavaScript makes creating and accessing global variables very easy. This is not a legitimate excuse, but it does make the examples easier to follow.

- Most of the examples are simple, 1-file programs where we can keep track of all the global variables. Global variables are still used by embedded programmers, as most embedded programs are relatively small and they allow for different types of CPU, RAM, or storage optimization.

Troubleshooting

- The Edison won’t connect– This is possible if the Edison is not powered or configured properly. See the “Edison won’t connect” section in the Appendix A: Troubleshooting.

- The LED doesn’t flash– Once again, check the wiring. Make sure you are connecting the base of the transistor to GP12 (through a 1kΩ resistor). Additionally, you can add some

console.log() statements in the code to see if certain parts are being executed.

Going Further

Challenges

- Make the LED turn on for 1 second and off for 1 second.

- Make the LED turn on for 200 ms and off for 1 second.

- Add a button (like in the previous experiment). Create a program such that the LED turns on only when the button is pushed.

Digging Deeper

Experiment 4: Email Notifier

Introduction

While flashing an LED is not the most interesting activity, we could use the LED as a way to notify us if something is happening. For example, we could turn on an LED if we have a new email. That way, we would know that we needed to check our inbox!

To do this, we will have the Edison log in to an email account, read the number of unread emails, and turn on an LED if it is over 0.

NOTE: This example shows how to connect to

Gmail and

Yahoo mail servers. If you are not using one of those, you still might be able to connect (see

here for a list of IMAP servers), but only Gmail and Yahoo have been tested. Also, you will need to enter your username and password as plain text into the code. It's a fun project, but you don't have to do it if you are not comfortable with that!

Parts Needed

We’ll be using the same circuit as in the previous example, so you don’t need to build anything new! In addition to the Edison and Block Stack, you will need the following parts:

- 1x Breadboard

- 1x RGB LED

- 1x NPN Transistor

- 1x 1kΩ Resistor

- 1x 100Ω Resistor

- 5x Jumper Wires

Using the Edison by itself or don't have the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

COM-10969

Resistors are a good thing, in fact, they're actually crucial in a lot of circuit designs. The only problem seems to be that …

65In stock

DEV-13045

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

9In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

17In stock

PRT-00116

A row of headers - break to fit. 40 pins that can be cut to any size. Used with custom PCBs or general custom headers.

**Fea…

18In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

18In stock

PRT-00115

Single row of 40-holes, female header. Can be cut to size with a pair of wire-cutters. Standard .1" spacing. We use them exte…

5In stock

DEV-13038

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

3In stock

DEV-13024

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

15In stock

COM-09264

Ever hear of a thing called RGB? Red, Green, Blue? How about an RGB LED? These 5mm units have four pins - Cathode is the long…

2In stock

COM-00521

These are very common, high quality BJT NPN transistors made by ST Micro.

**Datasheet: **[2N3904](http://www.sparkfun.com/da…

Suggested Reading

Concepts

External Modules

In the previous few examples, we have been relying on the MRAA module to control various hardware from the Edison. MRAA comes pre-installed on the Edison, so we did not have to perform any extra steps to install it. However, in this example, we will use node-imap, which contains several useful functions for connecting to Internet Message Access Protocol (IMAP) servers and retrieving email.

If we were to log in to the Edison via SSH or serial terminal, we could install Node.js packages (e.g. modules) using the npm command (e.g. npm install imap). However, with the XDK, we can tell the IDE to install necessary modules automatically whenever we upload code. This is accomplished by adding the library name to a list of dependencies in the project. The specifics on how to do this can be found in “The Code” section.

Callbacks

![MicroTAC Elite VIP cellular phone]()

I wonder if caller ID was a feature

A callback is a piece of code (often a function) that is expected to be called by another piece of code at a convenient time. A popular way to use callbacks in web programming is to assign a function to a mouse click event. For example:

language:JavaScript

element.on('click', myFunction);

myFunction() {

console.log("Hi!");

}

Whenever a user clicks on the web page element (called element in this example), myFunction() gets called. In this instance, myFunction() is the callback, and our assignment, element.on('click', myFunction);, is known as creating an event handler. See here to learn more about the .on() event handler.

Hardware Hookup

The circuit is the same as in the previous experiment.

![Red LED with Edison Fritzing]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

The Code

Create a new project in the XDK. Click on package.json in the files browser on the left pane. Add the line

language:JavaScript"imap": "0.8.16"

under "dependencies". This will tell the XDK to download and install the node-imap v0.8.16 module before running the program.

![Adding a new library]()

NOTE: If you are using Gmail, you will need to go to the

account security settings page and turn

access for less secure apps to

ON. We recommend turning it off once you are done with this exercise (unless you want to keep a permanent email notifier!).

Copy the following code into main.js. If you are not using Gmail, you can comment out (or delete) the part labeled “Set email credentials (Gmail)”. If you are using Yahoo, you will want to uncomment the part labeled “Set email credentials (Yahoo)”.

Finally, change the <username> and <password> parts to your actual email username and password.

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 4: Email Notifier

* This sketch was written by SparkFun Electronics

* October 29, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* Connect to an email service and turn on an LED if there are any unread

* emails.

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the MRAA and IMAP modules

var mraa = require('mraa');

var Imap = require('imap');

// Set up a digital output on MRAA pin 20 (GP12)

var ledPin = new mraa.Gpio(20);

ledPin.dir(mraa.DIR_OUT);

// It's usually a good idea to set the LED to an initial state

ledPin.write(0);

// Global LED variable to know if the LED should be on or off

var led = 0;

// Set email credentials (Gmail)

// Turn on "Acess for less secure apps" in Google account settings

// https://www.google.com/settings/security/lesssecureapps

var imap = new Imap({

user: "<username>@gmail.com",

password: "<password>",

host: "imap.gmail.com",

port: 993,

tls: true

});

// Set email credentials (Yahoo)

/*var imap = new Imap({

user: "<username>@yahoo.com",

password: "<password>",

host: "imap.mail.yahoo.com",

port: 993,

tls: true

});*/

// Open the mail box with the name "INBOX"

function openInbox(cb) {

imap.openBox("INBOX", true, cb);

}

// This is called when a connection is successfully made to the IMAP server.

// In this case, we open the Inbox and look for all unread ("unseen")

// emails. If there are any unread emails, turn on a LED.

imap.on('ready', function() {

openInbox(function(err, box) {

if (err) throw err;

// Search for unread emails in the Inbox

imap.search(["UNSEEN"], function(err, results) {

if (err) throw err;

// Print the number of unread emails

console.log("Unread emails: " + results.length);

// If there are unread emails, turn on an LED

if (results.length > 0) {

ledPin.write(1);

} else {

ledPin.write(0);

}

// Close the connection

imap.end();

});

});

});

// If we get an error (e.g. failed to connect), print that error

imap.on('error', function(err) {

console.log(err);

});

// When we close the connection, print it to the console

imap.on('end', function() {

console.log("Connection closed.");

});

// Call this function over and over again

periodicActivity();

function periodicActivity() //

{

// Perform a quick connection to the IMAP server and look for unread emails

imap.connect();

// Wait for 10 seconds before checking for emails again

setTimeout(periodicActivity, 10000);

}

What You Should See

When uploading the code, you might see some notifications that the XDK is downloading and installing npm packages. Just be patient while the packages are installed.

![XDK installing npm packages]()

When you run the code, it should connect to your email account and print to the console the number of unread emails every 10 seconds.

![Unread emails]()

I really should get in the habit of checking my emails more often

If you have one or more unread emails, the red LED should come on.

![Edison email notifier]()

Code to Note

Callbacks

I know that we talked about callbacks in the Concepts section, but now we get to see them in action. The node-imap package heavily relies on them, so it is important to get used to them if you plan to use that package in the future.

imap.on is used several times. This function gets called when something particular happens in our program. These are known as “Connection Events” according to the Application Program Interface (API) documentation. We can define particular connection events using strings.

For example, imap.on('ready', function() {...}); allows us to define a function (as noted by the function() keyword) that is called whenever a successful connection is made with the IMAP server.

imap.on('error', function() {...}); is called if there is a problem making a connection.

imap.on('end', function() {...}); is called whenever the connection with the server is closed.

There is another seemingly odd callback. In our imap.on('ready',...) code, we call openInbox(function(err, box) {...});. A few lines above, we define the openInbox() function, which tells the imap object to open our inbox and then call another function (as denoted by cb for “callback”). This callback function (cb) is the function we defined inside openInbox(function(err, box) {...});. So yes, we call a function that accepts another function as a parameter, which then calls that function as a callback. Don’t worry if this was confusing; it is a bit hard to follow. Knowing how to use the .on() callback functions is the most important part of this exercise.

Error Handling

Being able to appropriately deal with errors is a very useful ability in a program. The example relies on if (err) throw err; to determine if an error has occurred (e.g. could not connect to the IMAP server).

If we dig into the node-imap code, we would likely find a few catch statements. if (err) only executes the second part (throw err) if an err actually exists (not null or undefined). throw stops execution within that loop, function, etc., and program control is passed to the first catch statement it finds within the calling stack (e.g. look for a function that called the callback withing a try/catch statement).

If an error occurs, the node-imap module calls our callback function imap.on('error', function() {...});, which lets us handle the error. In this case, all we do is print the error to the console.

Troubleshooting

- It won’t connect to the IMAP server– This could be caused by several reasons:

- Make sure your Edison has Internet access

- Ensure you are using the correct IMAP server settings (Gmail and Yahoo examples are given in the code)

- Check that your email and password are correct in the code

- The LED won’t come on– As always, double-check the wiring. Make sure you are seeing

Unread emails: is appearing in the console, and that number is at least 1. Be patient, as it can take a few seconds for the program to make a connection to the IMAP server.

Going Further

Challenges

- Have the LED flash rapidly when there are unread emails.

- Have the LED turn on only when there are unread emails from a particular sender (e.g. a friend or your boss). You will need to carefully read the examples in the node-imap documentation.

- When you receive a new email, print its contents to the console and flash the LED. Hint: Take a look at the

mail(...) callback in Connection Events in the node-imap documentation.

Digging Deeper

Experiment 5: Web Page

Introduction

We know that we are exhausting this one LED circuit, but it really does prove useful in showing different features of the Edison. Hopefully, it spawns some cool project ideas for you! Just remember, if you can blink an LED, you can connect that output to any number of electrical devices. Relays, for example, are great for controlling more powerful components, like light bulbs, ceiling fans, and toasters. Additionally, going from an output (e.g. an LED) to an input (e.g. a button) is not too difficult.

Now that we have reached out to our email inbox to light an LED, why don’t we serve up a web page that allows us to control that LED? This experiment is divided into 2 parts. In the first section, we will create a basic web page that we can navigate to from any computer on the network. In the second section, we add a button to that page to allow control over an LED attached to the Edison.

Parts Needed

We’ll be using the same circuit as in the previous example, so you don’t need to build anything new! In addition to the Edison and Block Stack, you will need the following parts:

- 1x Breadboard

- 1x RGB LED

- 1x NPN Transistor

- 1x 1kΩ Resistor

- 1x 100Ω Resistor

- 5x Jumper Wires

Using the Edison by itself or don't have the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

COM-10969

Resistors are a good thing, in fact, they're actually crucial in a lot of circuit designs. The only problem seems to be that …

65In stock

DEV-13045

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

9In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

17In stock

PRT-00116

A row of headers - break to fit. 40 pins that can be cut to any size. Used with custom PCBs or general custom headers.

**Fea…

18In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

18In stock

PRT-00115

Single row of 40-holes, female header. Can be cut to size with a pair of wire-cutters. Standard .1" spacing. We use them exte…

5In stock

DEV-13038

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

3In stock

DEV-13024

The Intel® Edison is an ultra small computing platform that will change the way you look at embedded electronics. Each Ediso…

15In stock

COM-09264

Ever hear of a thing called RGB? Red, Green, Blue? How about an RGB LED? These 5mm units have four pins - Cathode is the long…

2In stock

COM-00521

These are very common, high quality BJT NPN transistors made by ST Micro.

**Datasheet: **[2N3904](http://www.sparkfun.com/da…

Suggested Reading

- How Web Servers Work– A look at how information is served to your computer when you browse a web site

- Introduction to HTML– HyperText Markup Language (HTML) is a fairly old computer language still in use today to create web pages. We will be using some HTML to make our web page.

- WebSockets– We will use the socket.io module in the second part of this exercise to implement WebSockets. This will allow us to create a connection between the Edison and another computer so we can simple commands (like toggle an LED).

Concepts

Browsing to a Web Page

![Connected computers and the Internet]()

It’s like a series of tubes!

In simplest terms, when you “browse to a web page,” your computer makes a request to a remote server somewhere on the Internet. The actual server (physical computer) you are accessing can be anywhere in the world (assuming it also has Internet access). The server then sends an HTML file back to your computer, which your browser (Chrome, Safari, Firefox, IE, etc.) parses and displays the HTML elements in a human-readable format.

We will be constructing a very simple web page on our Edison using HTML. We will use the Node.js http module to create this page and host it as a web server from within the Edison. As a result, we can browse to the Edison from any computer on the same network, and it will show us a web page!

WebSockets

WebSockets is another protocol for sending and receiving messages across the Internet (or other networked computers). As long as Transmission Control Protocol (TCP) can be realized on the network, WebSockets can be used to transmit messages. WebSockets is similar to HyperText Transfer Protocol (HTTP) in that they both rely on TCP and are used for transmitting data across a network. However, WebSockets uses far less overhead and can be used for communication between client and server with lower latency than HTTP. See this article to read more about WebSockets vs. HTTP.

In the second part of this experiment, we rely on the socket.io module to handle WebSockets in JavaScript for us. This allows us to create a connection from our browser (on our host computer) to the web server running on the Edison and send messages back and forth. We will use a simple message that causes an LED connected to the Edison to turn on and off.

Hardware Hookup

The circuit is the same as in the previous experiment.

![Red LED with Edison Fritzing]()

Having a hard time seeing the circuit? Click on the Fritzing diagram to see a bigger image.

Part 1: A Simple Web Page

The Code

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 5 - Part 1: Web Page

* This sketch was written by SparkFun Electronics

* November 1, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* Serves a very simple web page from the Edison.

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the HTTP module

var http = require('http');

// Which port we should connect to

var port = 4242;

// Create a web server that serves a simple web page

var server = http.createServer(function(req, res) {

res.writeHead(200);

res.write("<!DOCTYPE html> \<html> \<head> \<title>My Page</title> \</head> \<body> \<p>This is my page. There are many like it, \

but this one is mine.</p> \</body> \</html>");

res.end();

});

// Run the server on a particular port

server.listen(port, function() {

console.log('Server listening on port ' + port);

});

What You Should See

Upload and run the code on the Edison. The console should notify you with Server listening on port 4242. Open a web browser and navigate to http://<Edison's IP address>:4242. You can find the Edison’s IP address from the XDK under the IoT Device: drop-down menu. For example, my Edison had the IP address of 10.8.0.171, so I navigated to http://10.8.0.171:4242 in my browser.

![Edison hosting a web page]()

Viewing our web page from the host computer

If you have another computer or a smartphone that is on the same network as the Edison, you can also try navigating to the same page.

![alt text]()

Viewing the same web page from a smartphone

Note that we are not using the LED in this part, that’s next!

Code to Note

This example is a special case where we write 2 different languages in one file. While most of our code is JavaScript, we write HTML as one long string as an input to the res.write() function. res is the response of our server, so it sends out the string inside res.write() to the client whenever a request is made. Note that we use the character ‘\’ to separate lines in a string in JavaScript. The ‘\’ is ignored, but it prevents the string from ending when we move to a new line.

HTML uses tags, as noted by the <> characters, to tell the browser how to structure the page and display text. For example, you could put <b> and </b> around some text to make it bold (try it!). In our example, we use <head> to mark the header of the page, which appears in the tab or title bar, and <body> to mark the main part of the page, which is the text that appears in the browser window. To learn more about tags, see here.

Part 2: Web Page Button

The Code

Add "socket.io": "1.3.7" to "dependencies" in package.json, which should look like:

language:JavaScript

{"name": "blankapp","description": "","version": "0.0.0","main": "main.js","engines": {"node": ">=0.10.0"

},"dependencies": {"socket.io": "1.3.7"

}

}

In main.js, copy in the following code:

language:JavaScript

/*jslint node:true, vars:true, bitwise:true, unparam:true */

/*jshint unused:true */

// Leave the above lines for propper jshinting

/**

* SparkFun Inventor's Kit for Edison

* Experiment 5 - Part 2: Web Page Button

* This sketch was written by SparkFun Electronics

* November 1, 2015

* https://github.com/sparkfun/Inventors_Kit_For_Edison_Experiments

*

* Serves a web page that allows users to turn an LED on and off remotely.

*

* Released under the MIT License(http://opensource.org/licenses/MIT)

*/

// Import the MRAA and HTTP modules

var mraa = require('mraa');

var http = require('http');

// Set up a digital output on MRAA pin 20 (GP12) for the LED

var ledPin = new mraa.Gpio(20);

ledPin.dir(mraa.DIR_OUT);

ledPin.write(0);

// Global LED variable to know if the LED should be on or off

var led = 0;

// Which port we should connect to

var port = 4242;

// Create a web server that serves a simple web page with a button

var server = http.createServer(function(req, res) {

res.writeHead(200);

res.write("<!DOCTYPE html> \<html> \<head> \<title>LED Controller</title> \<script src='/socket.io/socket.io.js'></script> \</head> \<body> \<p><button onclick='toggle()'>TOGGLE</button></p> \<script> \

var socket = io.connect('http://" +

req.socket.address().address + ":" +

port + "'); \

function toggle() { \

socket.emit('toggle'); \

} \</script> \</body> \</html>");

res.end();

});

// Listen for a socket connection

var io = require('socket.io').listen(server);

// Wait for a client to connect

io.on('connection', function(socket) {

console.log('A client is connected!');

// Look for the "toggle" message from the client, and toggle the LED

socket.on('toggle', function() {

led = led ? 0 : 1;

ledPin.write(led);

});

});