Introduction to the Johnny-Five Inventor's Kit

In stock

KIT-13847

The Johnny-Five Inventor's Kit (J5IK) is your go-to source for developing projects using the Tessel 2 and the Johnny-Five pro…

The Johnny-Five Inventor’s Kit you have in front of you is your toolkit, and this Experiment Guide is your map. We’re going to dive into the world of embedded electronics, JavaScript, the internet, and the way they come together as the “Internet of Things” (IoT). The Johnny-Five JavaScript framework provides a beginner-friendly way to start building things—quickly. This guide contains all the information you need to successfully build the circuits in all 14 experiments. At the center of this guide is one core philosophy: that anyone can (and should) play around with basic electronics and code.

When you’re done with this guide, you’ll have the know-how to start creating your own projects and experiments. You can build robots, automate your home, or log data about the world around you. The world, in fact, will be your hardware-hacking oyster. Enough inspirational sentiment — let’s get building!

Note: To get started with this guide you will need to have an internet connection and administrative privileges on the computer that you are using.

Included Materials

Here are all of the parts in the Johnny-Five Inventor’s Kit for the Tessel 2 (J5IK):

- Tessel 2— The Tessel 2 Single-Board Computer (SBC)

- USB-A to USB micro B— for connecting your computer to the Tessel 2

- Wall Charger (5V, 1A)— Gotta power the Tessel 2 somehow! This charger makes it easy to power your projects!

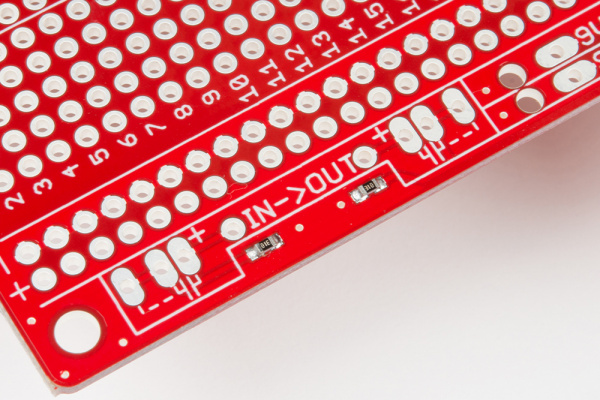

- Breadboard— This perforated grid is the ticket to easy experimentation with circuits.

- Carrying Case— Take your kit anywhere with ease!

- Jumper wires— These multi-colored wires with pins on each end making connecting things together a breeze.

- Rainbow Pack of LEDs— LEDs are indispensable. Here’s a whole rainbow of ‘em.

- 100 Ohm Resistors— These are just about right for using with LEDs at 3.3V (the voltage we’ll be using for the circuits in this guide)

- 10K Ohm Resistors— These make excellent pull-ups, pull-downs and current limiters (don’t worry if you haven’t seen these terms before)

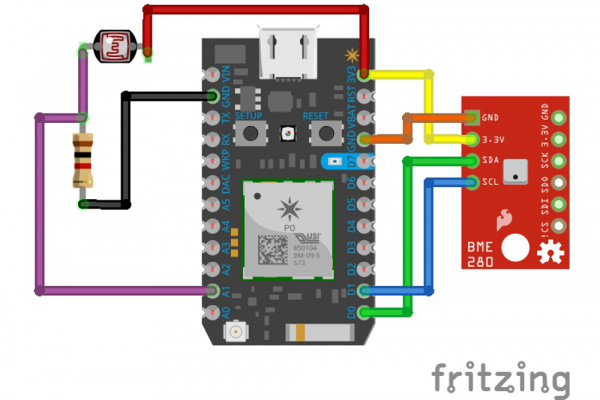

- Photocell— A sensor that detects ambient light. Also called a photoresistor. Perfect for detecting when a drawer is opened or when nighttime approaches.

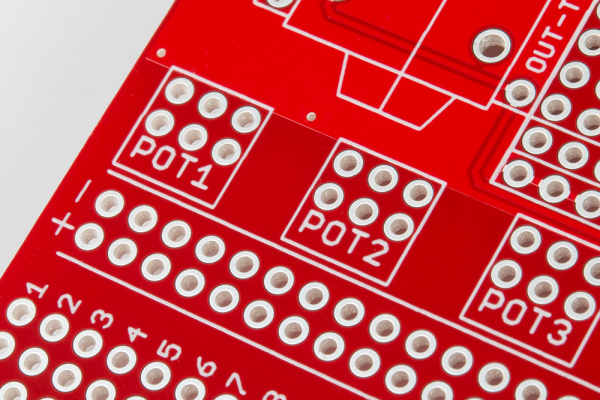

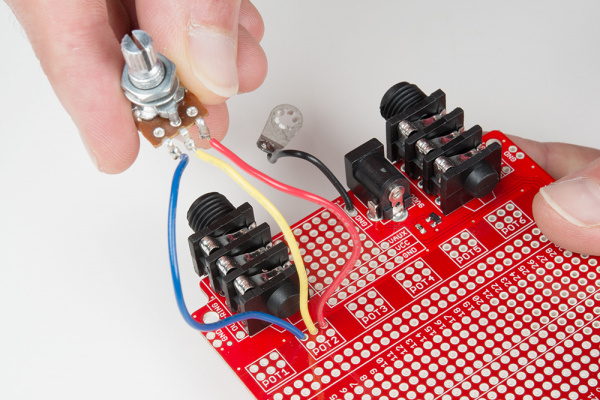

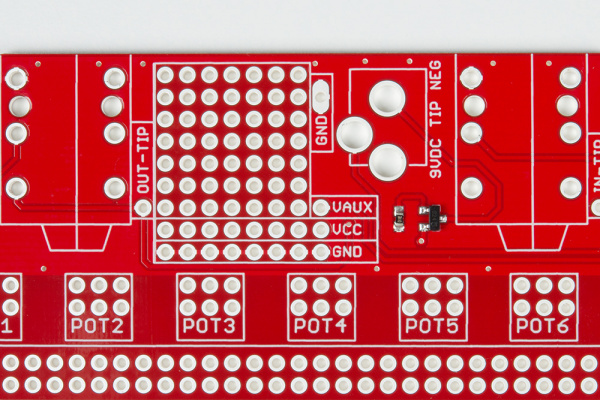

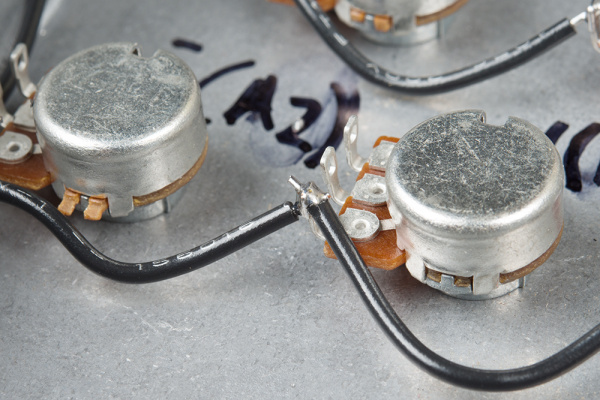

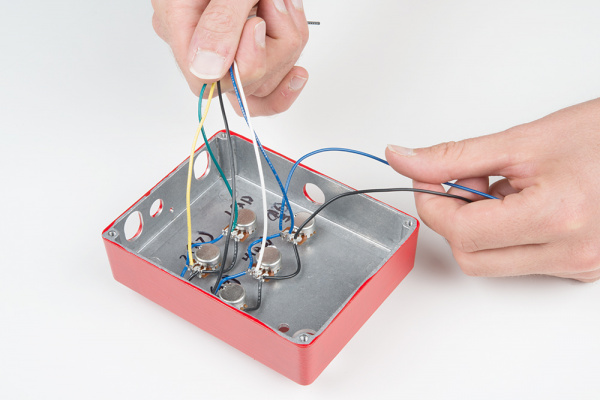

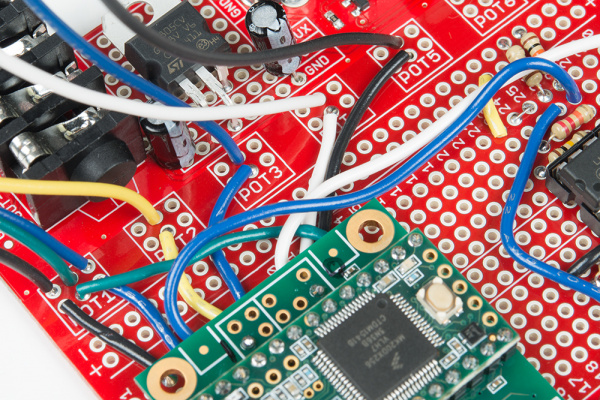

- 10KΩ Trimpots— Also known as a variable resistor or a potentiometer, this is a device commonly used to control volume and contrast (it usually has a dial or a slider), and makes a great general user control input.

- Red, Blue, Yellow and Green Tactile Buttons— These fun-to-press buttons give you several colors to choose from.

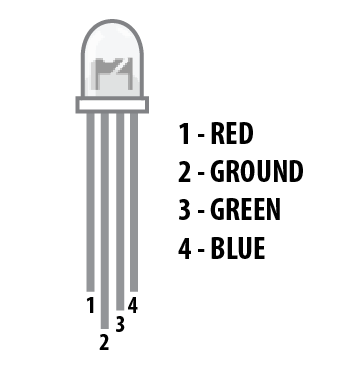

- RGB LED— Why use an LED that can only be one color when you can have any color?

- SPDT (Single-Pole, Dual Throw) Switch— It’s a switch! You slide it back and forth, and it fits into a breadboard just great.

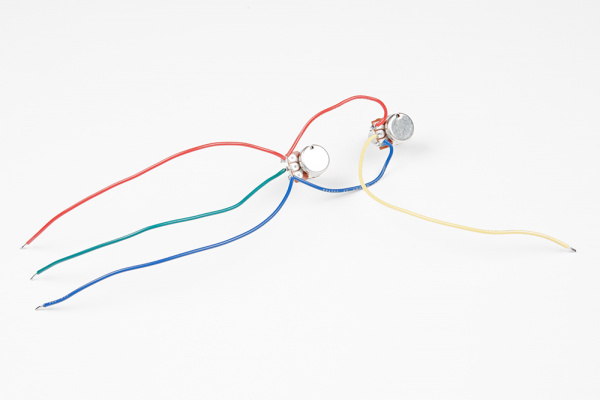

- Magnetic Door Switch— A mountable magnetic switch used in home automation and security. Great for detecting when a door or drawer is opened!

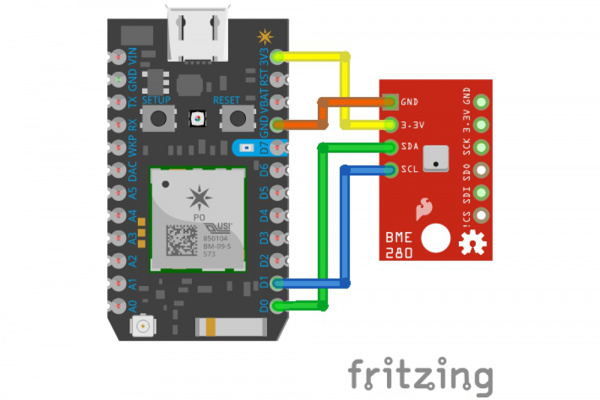

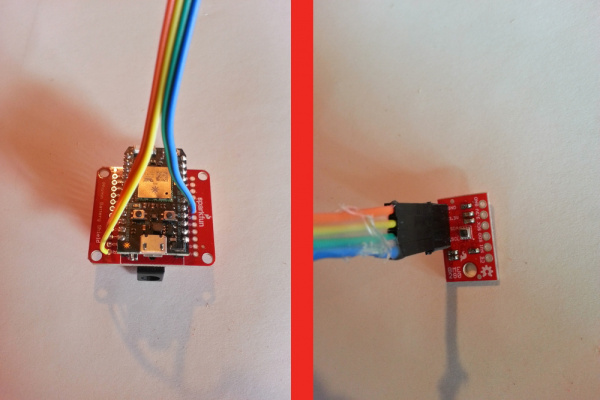

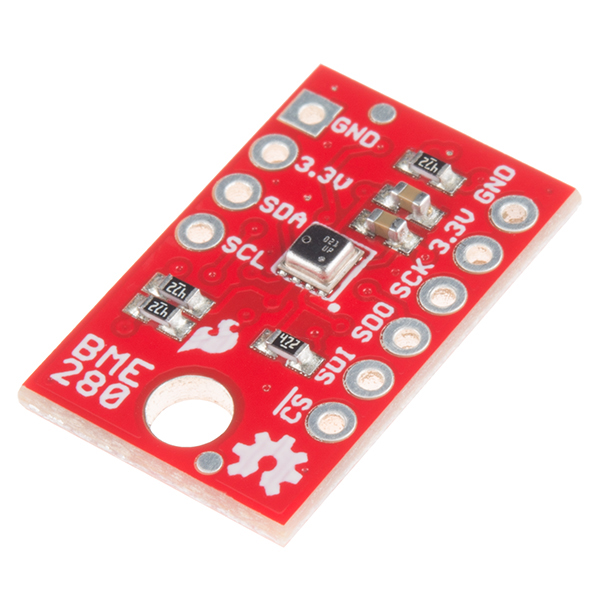

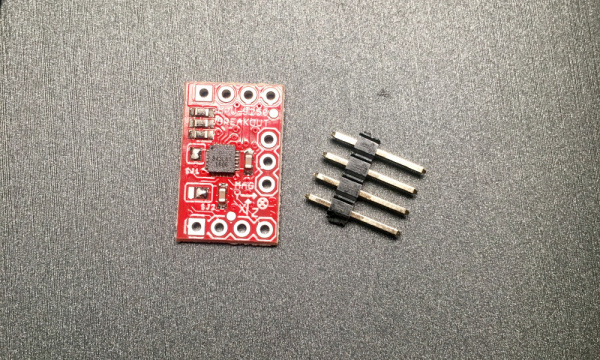

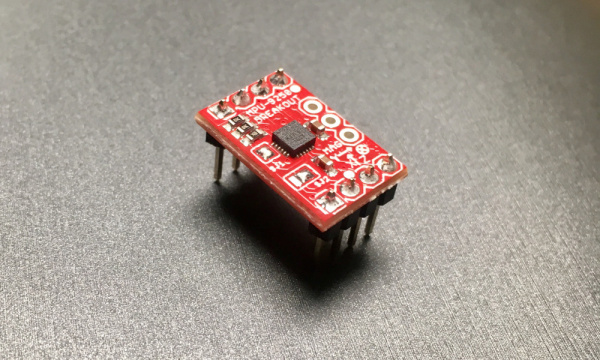

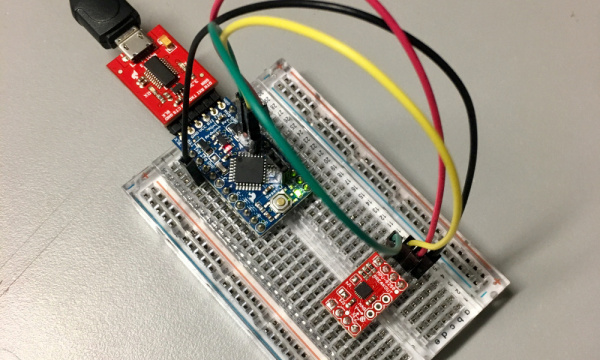

- BME280 Atmospheric Sensor Breakout— A sensor for detecting temperature, pressure and humidity. It communicates using the I2C serial communication protocol. The header pins are soldered on for you, which makes connecting this to your project nice and easy.

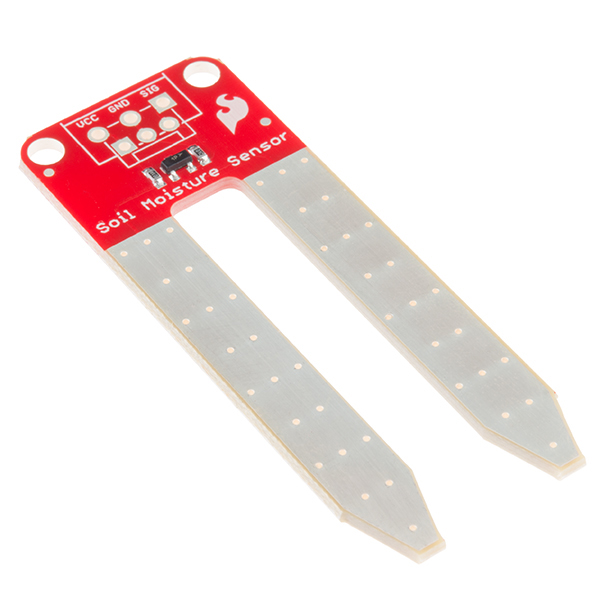

- Soil Moisture Sensor— The name describes it pretty well!

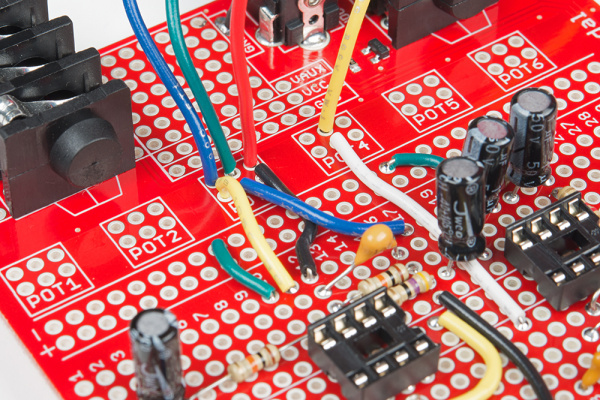

- SparkFun Motor Driver— This nifty little board is perfect for controlling the speed and direction of up to two separate motors.

- Hobby Gearmotor Set— A set of hobby level motors (two of ‘em) with gearboxes set to 120 RPM.

- 7 Segment Display— It’s an LED that lets you display numerals via the combination of lit-up segments, just like an alarm clock from the 1980s!

- 3.3V 16x2 White on Black LCD— This LCD can display 16 characters on two lines with a snazzy white-on-black background appearance. It operates at 3.3 volts (this is the voltage that the Tessel 2 is most comfortable with).

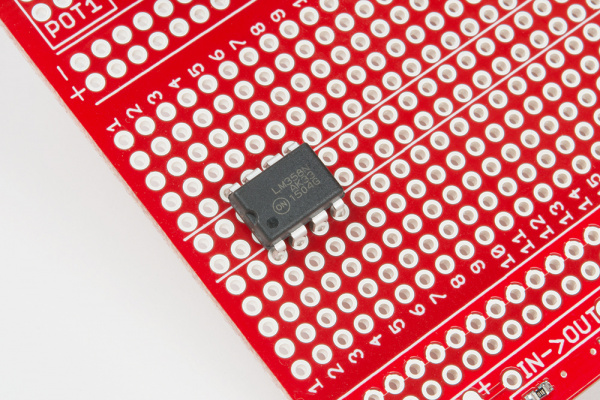

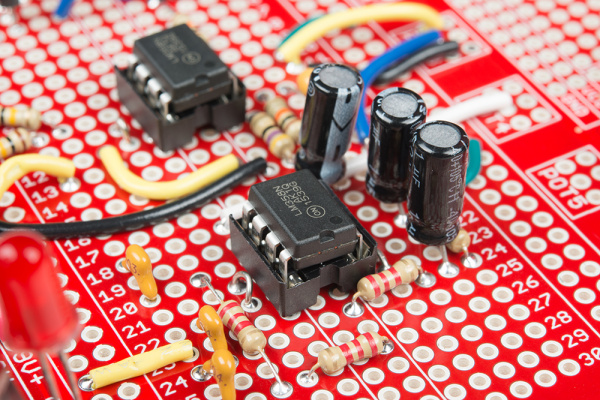

- 74HC595 Shift Register— An integrated circuit (IC) that allows you to increase the number of inputs and outputs you can control from a microcontroller.

Suggested Reading

While you can get through this guide without doing any outside reading, the following tutorials cover the essential core of electronics and circuits and are super useful:

What is a Circuit?

Every electrical project starts with a circuit. Don't know what a circuit is? We're here to help.

How to Use a Breadboard

Welcome to the wonderful world of breadboards. Here we will learn what a breadboard is and how to use one to build your very first circuit.

Analog vs. Digital

This tutorial covers the concept of analog and digital signals, as they relate to electronics.

Open Source!

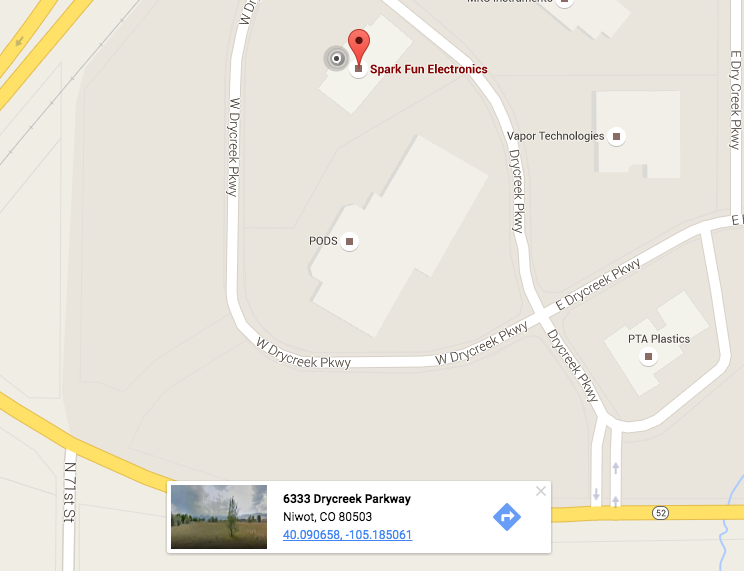

At SparkFun, our engineers and educators are constantly improving kits such as these and coming up with new experiments. We would like to give attribution to Rick Waldron and Bocoup, as he originally started the development of Johnny-Five many years ago. The contents of this guide are licensed under the Creative Commons Attribution Share-Alike 4.0 Unported License.

To view a copy of this license visit this link, or write: Creative Commons, 171 Second Street, Suite 300, San Francisco, CA 94105, USA.

About the Tessel 2

![!The Tessel 2 Development Board]()

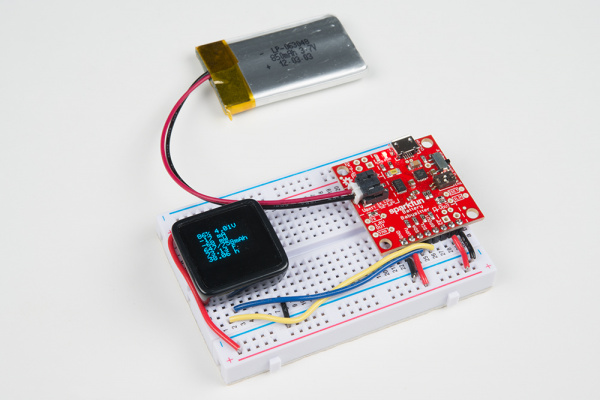

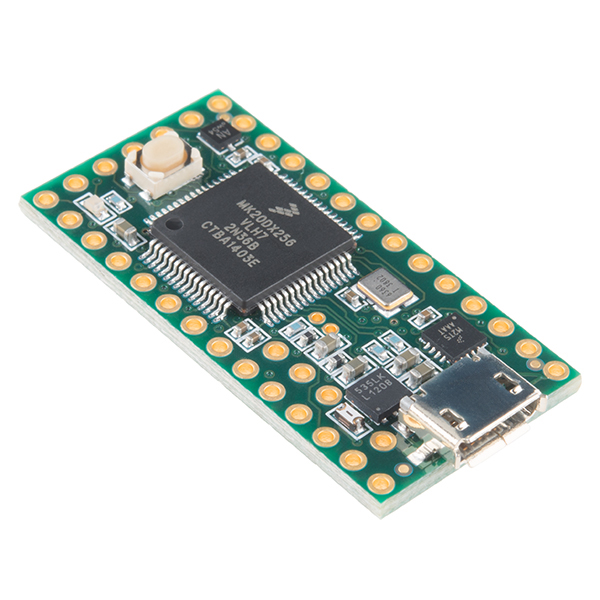

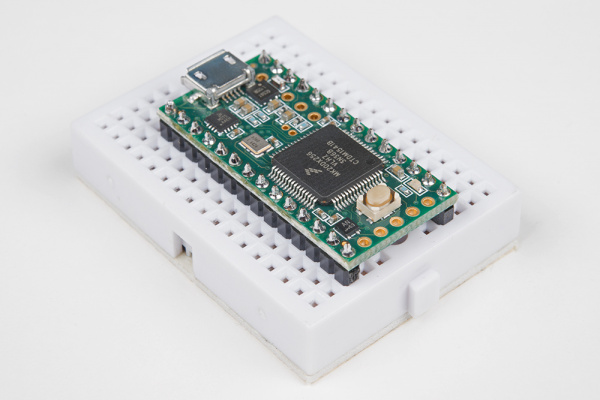

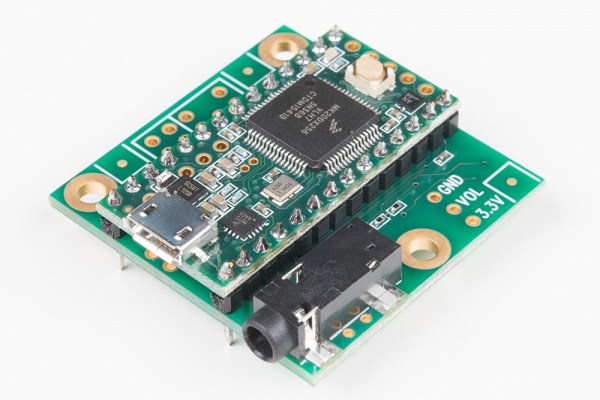

The Tessel 2 is an open-source development board. It runs JavaScript and supports npm, which means scripts to control it can be built with Node.js. It’s a platform for experimenting, tinkering, prototyping and producing embedded hardware, perfect for the Internet of Things.

OK, So What’s a Development Board?

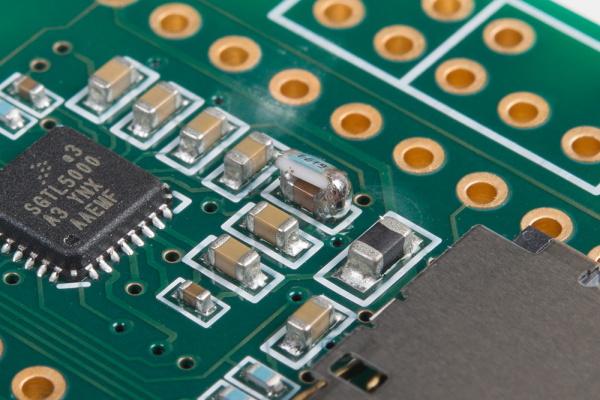

Development boards are platforms for prototyping and building embedded systems. At the heart of (most) development boards is a microcontroller, which combines a processor and memory with IO capabilities. Microcontrollers like the one on the Tessel 2 provide a collection of GPIO (general-purpose IO) pins for connecting input and output devices to. The pins on the microcontroller itself—a chip—are small, too small for human fingers to work with easily (plus you’d need to solder things to them). Development boards instead connect these GPIO pins to pin sockets that are easy to plug things into.

Other common features of boards play a supporting role: connections for programming and communicating with the board, status lights and reset buttons, power connections.

More powerful boards like the Tessel 2 and the well-known Raspberry Pi are sometimes also called single-board computers (SBCs).

Tessel 2’s Features

The Tessel is a mighty little board. Some of Tessel 2’s specifications include:

- 2 USB ports (you can connect cameras or flash storage, for example)

- 10/100 ethernet port

- 802.11 b/g/n WiFi

- 580MHz Mediatek router-on-a-chip (you can turn your Tessel 2 into an access point!)

- 48MHz SAMD21 coprocessor (for making IO zippy)

- 64MB DDR2 RAM, 32MB of flash (lots of space for your programs and stuff)

Working with Tessel 2

Tessel has a set of command-line interface (CLI) tools for setting up and working with the Tessel 2 board. You’ll install these and do a one-time set-up provisioning of your Tessel.

You can write scripts for the Tessel 2 in any text editor, using JavaScript and including npm modules as you desire. A one-line terminal command deploys and executes your script on the Tessel.

Inputs and Outputs

There are two primary sets of pins on the Tessel 2: Port “A” and Port “B”. Each port has 10 pins: two pins for power (3.3V and ground) and eight GPIO pins.

![The Tessel 2's GPIO pins: Port A and Port B]()

Some pins support different features. You can read details about every Tessel 2 pin, or just keep that info handy for reference later.

Powering the Board

There are multiple ways to power the Tessel 2. We’ll start by using the included USB cable.

Over USB

![alt text]()

Connecting to the board directly with USB will allow you to easily modify any circuits and re-deploy code from the comfort of your desk, without having to retrieve your project. This is also handy when you don’t have access to the local network (for deploying code over WiFi).

USB Wall Charger

![alt text]()

Once you have completely set up and provisioned your Tessel 2, you can deploy code through your local WiFi network. At some point you’ll itch to make your Tessel free of wires and tethering, but it still needs power. We supplied a 5V USB charger in the J5IK so you can place your project in a semi-remote location around your home or office and deploy code from anywhere on your local network.

USB Battery Pack

![alt text]()

USB Battery packs are becoming quite popular as swag and giveaways at events. We collect them like candy because they allow us to power projects with minimal consideration to power management circuitry. If you have one of these handy, just use the included USB cable to plug the Tessel 2 into your battery and away you go! That’s it, simple as pie.

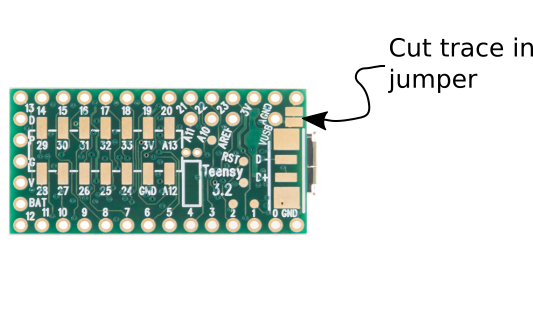

Ports and Pins on the Tessel 2

The Tessel 2 has two IO modules, Port A and Port B. Each port has 8 GPIO (general-purpose I/O) pins. Here’s their naming conventions and what all of them do.

![alt text]()

Pin Naming Conventions

The pins on the Tessel 2 are broken out across the two different ports. The naming conventions in code will be referenced with the port letter first and then the pin number of that port. The port letter is not case sensitive! As an example, the first pin on port A would be referred to as pin a0 or A0. Use this table as a reference in terms of the naming of pins.

| Port | Pin Number | Johnny-Five Name |

|---|

| A | 0 | “a0” or “A0” |

| A | 1 | “a1” or “A1” |

| A | 2 | “a2” or “A2” |

| A | 3 | “a3” or “A3” |

| A | 4 | “a4” or “A4” |

| A | 5 | “a5” or “A5” |

| A | 6 | “a6” or “A6” |

| A | 7 | “a7” or “A7” |

| B | 0 | “b0” or “B0” |

| B | 1 | “b1” or “B1” |

| B | 2 | “b2” or “B2” |

| B | 3 | “b3” or “B3” |

| B | 4 | “b4” or “B4” |

| B | 5 | “b5” or “B5” |

| B | 6 | “b6” or “B6” |

| B | 7 | “b7” or “B7” |

Pin Capabilities: What Each Pin Can Do

The pins of each port have different functionalities available to them.

Other things to know:

- All eight numbered pins, both ports (16 total), can be used as GPIO.

- Pins

4 and 7 on Port A support analog-to-digital input. All pins on Port B support analog input. - Pins

5 and 6 on both ports support Pulse-Width Modulation (PWM). - Pins

0 and 1 on both ports can be used for I2C serial communication. - Serial TX/RX (hardware UART) is available on both port, pins

5 (TX) and 6 (RX). - Port B, Pin

7: Supports digital-to-analog conversion (DAC)

The two ports are essentially duplicates, with the following exceptions:

- Port B: All numbered pins can be used for analog input.

- Port B, Pin

7: Supports DAC.

For exhaustive details, see the pin functionality reference chart below:

| Port | Pin Number | Digital I/O | SCL | SDA | TX | RX | Analog In | Analog Out | Interrupt | PWM |

|---|

| A | 0 | | | | | | | | | |

| A | 1 | | | | | | | | | |

| A | 2 | | | | | | | | | |

| A | 3 | | | | | | | | | |

| A | 4 | | | | | | | | | |

| A | 5 | | | | | | | | | |

| A | 6 | | | | | | | | | |

| A | 7 | | | | | | | | | |

| B | 0 | | | | | | | | | |

| B | 1 | | | | | | | | | |

| B | 2 | | | | | | | | | |

| B | 3 | | | | | | | | | |

| B | 4 | | | | | | | | | |

| B | 5 | | | | | | | | | |

| B | 6 | | | | | | | | | |

| B | 7 | | | | | | | | | |

Software Installation and Setup

Let’s prepare the software side of things so you’re ready to build stuff in this guide. You’ll need to have a few things installed, and you’ll want to set up a project area for your JavaScript programs. So, don’t skip ahead!

Installing Needed Things

You’re going to need:

- A text editor

- Node.js

- A terminal application

Installing a Text Editor: Atom

You will need a text editor in which to edit and save your JavaScript files. This means a plain text editor, not a Word document. If you’ve already got one, like SublimeText, Notepad++, vim, etc., groovy. If not, go ahead and install Atom.

![atom text editor logo]()

You can use any text editor you like if you already have on installed and are up and running. But, if you have never used a text editor to write JavaScript, HTML, etc. we recommend using Atom. Atom is a free and open source text editor that works on all three major operating systems, is light weight and when you get comfortable…it’s hackable!

Download Atom by heading to the Atom website.

![alt text]()

Installing Node.js

![node.js logo]()

Node.js is a JavaScript runtime, that is, it’s software that can execute your JavaScript code. Node.js has special features that support some of the best potentials of the JavaScript programming language, like event-driven, non-blocking I/O. npm is Node’s package manager. It’s a giant repository of encapsulated bits of reusable useful code, called modules, that you can use in your programs. npm will get installed for you when you install Node.js.

![alt text]()

Installing Node.js is a straightforward download-and-double-click process. Head on over to the Node.js website. Heads up: You’ll want to select the “LTS” version for download (LTS stands for long-term support). At time of writing, LTS is v4.4.5:

![alt text]()

Using a Terminal: Command Line Basics

Working with the Tessel is just like doing web development. But if you’re not familiar with web development, you might want to take a minute or two to get comfortable with some key tools of the trade: the command line (the “terminal”, where you execute commands) and the text editor, where you will work on and save your programs. Tessel’s site has a great resource to help you get started with terminal.

In the context of this tutorial, things that should be run in the command line look like this:

hello i am a command line command!

You’ll see this when you get to the first experiment. But, don’t skip ahead—you’ll need the tools we install in the next step.

Setting up a Project Working Area

Take a moment to set up a working area (directory) where you can put the programs for your Johnny-Five Inventor Kit (J5IK). You’ll also need to initialize the new project with npm and install needed npm modules for both Johnny-Five and Tessel.

You can accomplish all of this by typing (or copying and pasting) the following commands in a terminal:

mkdir j5ik;

cd j5ik;

npm init -y;

npm install johnny-five tessel-io;

Running these commands will generate some output in your terminal. If everything goes smoothly, you’ll see some output about edits to a package.json file, and some additional output as npm installs the needed modules. You may also see a few WARN statements about missing description or repository field. Don’t worry—nothing’s broken.

An example of the kind of output you’ll see (though yours will differ in some particulars):

Wrote to /your/path/j5ik/package.json:

{"name": "j5ik","version": "1.0.0","description": "","main": "index.js","scripts": {"test": "echo \"Error: no test specified\"&& exit 1"

},"keywords": [],"author": "","license": "ISC"

}

j5ik@1.0.0 /your/path/j5ik

├── johnny-five

└── tessel-io

npm WARN j5ik@1.0.0 No description

npm WARN j5ik@1.0.0 No repository field.

Hardware Installation and Setup

It’s time to get your Tessel 2 set up. The steps we’ll walk through now include:

- Installing the

t2-cli software tool - Connecting the Tessel 2 with a USB cable

- Finding, renaming and provisioning the Tessel

- Updating the Tessel’s firmware

Installing the Command-Line Tool

Note to Linux users:- If you are making a global installation on a Linux computer, be sure to add sudo in front of your npm installation command!

- Some Linux distrobutions require a few more library installs for `t2-cli` to work! Please install the libraries with the following command: apt-get install libusb-1.0-0-dev libudev-dev. You can find further documentation here.

You interact with the Tessel 2 using a command-line interface (CLI) tool called t2-cli. This tool can be installed using npm (Node.js' package manager, which gets installed automatically with Node.js).

Type the following into your terminal:

npm install t2-cli -g

The -g piece of that command (a flag) is important—this will tell npm to install the package globally, not just in the current project or directory.

The installation will take a few moments, and you will see a bunch of stuff scroll by that looks sort of like this:

![alt text]()

Troubleshooting

Note: If you see any warnings or errors when trying to install t2-cli, the first thing to check is your Node.js version. To do this, type the following command in your terminal:

node –version

You’re aiming for the LTS (long-term support) version of Node.js, which at time of writing is v4.4.5. Learn more about how to upgrade and manage node versions with nvm.

Setting up your Tessel!

Now, time to get your hands dirty and get things up and running! Connect your Tessel 2 to your computer and give it about 30 seconds to boot up.

![alt text]()

Once your Tessel 2 has booted (the blue LED will be steady instead of blinking), type the following command into your terminal:

t2 list

The t2-cli tool will look for connected Tessels. Tessels can be connected by USB or over WiFi, but for now, it should spot your single, USB-connected Tessel. You’ll see something like this:

![alt text]()

Success! You can now communicate with your Tessel 2!

Naming Your Tessel 2

Giving your Tessel 2 a name is not required to use it, but it’s fun and friendly. To name your Tessel 2 use the following command:

t2 rename [name]

For example we renamed our Tessel 2 “Bishop” by typing following.

t2 rename bishop

The t2-cli tool will respond with the following output:

![alt text]()

Double-check it!

t2 list

![alt text]()

Connecting Your Tessel 2 to the Internet

If you’ve ever configured and connected other embedded systems to the Internet, the simplicity of this should make you grin.

You’ll need to be connected to your local WiFi network first. To connect your Tessel to a WiFi network, type the following command into your terminal:

t2 wifi -n [SSID] -p [password]

Replace [SSID] with the name of your wireless network (careful! It’s case-sensitive) and [password], well, I be you can figure that out!

You’ll see some output that looks something like the following:

INFO Looking for your Tessel...

INFO Connected to bishop.

INFO Wifi Enabled.

INFO Wifi Connected. SSID: your-network-ssid, password: your-network-password, security: psk2

That’s it! Simple as pie!

You can do a bunch of other stuff with your Tessel and network connectivity. Tessel’s website has in-depth documentation on WiFi connection options.

Troubleshooting

Note: Like Kindles and some Androids, Tessel 2’s don’t play nice with 5GHz WiFi networks.

Provision Your Tessel 2

Your Tessel exists, has a name, and is connected to your WiFi network. The next step is to provision the Tessel. That creates a secure, trusted connection between your computer and the Tessel, whether it’s connected by wire or over the air (WiFi). You’ll need to do this before you can deploy code to the Tessel.

Type the following command in your terminal:

t2 provision

You’ll see something like:

INFO Looking for your Tessel...

INFO Connected to bishop.

INFO Creating public and private keys for Tessel authentication...

INFO SSH Keys written.

INFO Authenticating Tessel with public key...

INFO Tessel authenticated with public key.

Verify it worked:

t2 list

You’ll see your Tessel twice! That’s because it’s connected via USB and WiFi.

INFO Searching for nearby Tessels...

USB bishop

LAN bishop

Great! We have one last setup step.

Update Your Tessel 2

The Tessel community is constantly improving the software and firmware for the Tessel 2. It’s likely that in the time between your Tessel 2’s manufacture and now, the firmware has been updated. To update your Tessel, type the following command in your terminal:

t2 update

The update process can last some time, so I would recommend a snack break or checking up on some news feeds while this happens. When the update is finished you will get the command prompt back, and you are all ready to go with your Tessel 2!

Experiment 1: Blink an LED

Introduction

Making an LED (Light-Emitting Diode) blink is the most basic “Hello, World!” exercise for hardware, and is a great way to familiarize yourself with a new platform. In this experiment, you’ll learn how to build a basic LED circuit and use Johnny-Five with your Tessel 2 to make the LED blink and pulse. In doing so, you’ll learn about digital output and Pulse Width Modulation (PWM).

Perhaps you’ve controlled LEDs before by writing Arduino sketches (programs). Using Johnny-Five + Node.js to control hardware is a little different, and this article will illustrate some of those differences. If you’re totally new to all of this — not to worry! You don’t need any prior experience.

Parts Needed

You will need the following parts for this experiment:

- 1x Tessel 2 and USB cable

- 1x Breadboard

- 1x Standard LED (Choose any color in the bag full of LEDs)

- 1x 100Ω Resistor

- 2x Jumper Wires

Using a Tessel 2 without the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

24In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

PRT-12795

These are 6" long jumper wires with male connectors on both ends. Use these to jumper from any female header on any board, to…

1In stock

DEV-13841

The Tessel 2 is a development board with on-board WiFi capabilities that allows you to build scripts in Node.js. This Tessel …

In stock

COM-13761

These are 1/4th Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 100 Ohm resistors m…

Suggested Reading

The following tutorials provide in-depth background on some of the hardware concepts in this experiment:

Introducing LEDs

Diodes are electronic components that only allow current to flow through them in a single direction, like a one-way street. Light-Emitting Diodes (LEDs) are a kind of diode that emit light when current flows through them.

![Photo of a standard red LED]()

Grab an LED and take a look at it. The longer leg is called the anode. That’s where current enters the LED. The anode is the positive pin and should always be connected to current source. The shorter leg, the cathode, is where current exits the LED. The cathode is the negative pin and should always be connected to a pathway to ground. Many LEDs also have a flat spot on the cathode (negative) side.

![Drawing of LED parts: anode and cathode]()

If you apply too much current to an LED, it can burn out. We need to limit the amount of current that passes through the LED. To do that, we’ll use a resistor. When you use a resistor in this way to limit current, it is called — surprise! — a current-limiting resistor. With the Tessel 2 board, you should use a 100 Ohm resistor. We have included a baggy of them in the kit just for this reason!

If you’re curious to learn more about how voltage, current and resistance relate to one another, read this tutorial about Ohm’s Law.

Hardware Hookup

Its now the fun part! It’s time to start building your circuit. Let’s take a look at what goes into building this circuit.

Polarity

LEDs are polarized, meaning they need to be oriented in a specific direction when they are plugged in. You don’t want to plug a polarized part in backward!

On the other hand, resistors are not polarized; they’re symmetric, which means they don’t have an opinion about which way current flows across them. You can plug a resistor in facing either direction in a circuit, and it will be just fine.

Plugging Things In

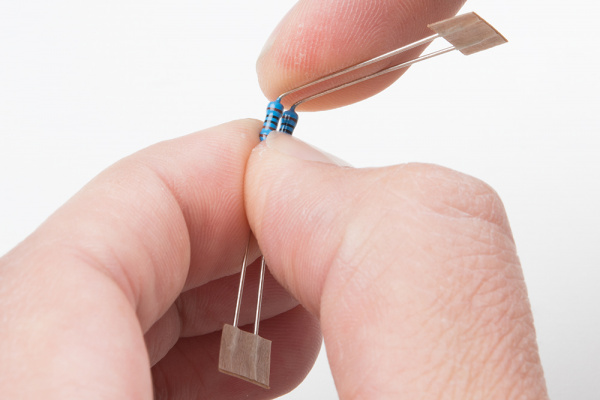

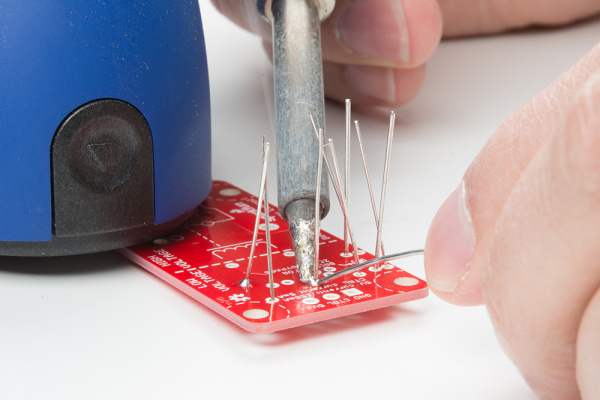

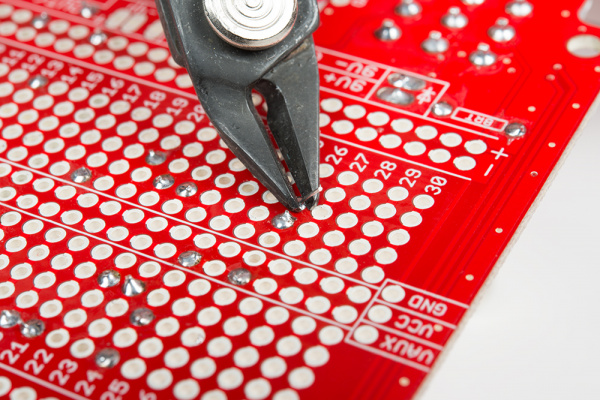

When working with components like resistors, you’ll need to bend their legs at (about) 90° in order to correctly fit into the breadboard sockets. You can trim the legs shorter to make them easier to work with, if you like:

![Bent resistor]()

All jumper wires work the same. They are used to connect two points together. All of the experiments in this guide will show the wires with different colored insulations for clarity, but using different combinations of colors is completely acceptable.

![Image of jumper wires]()

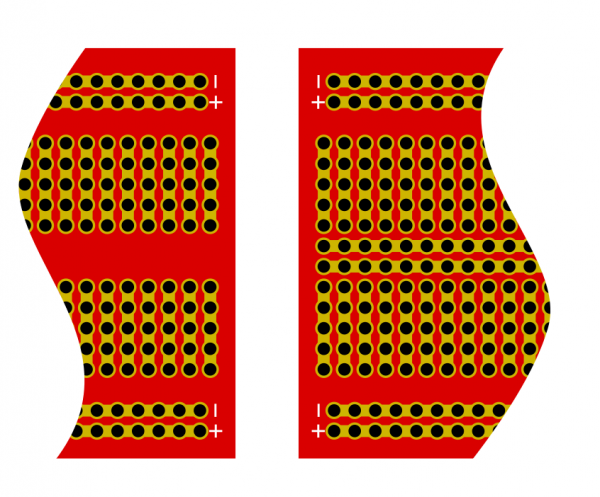

Breadboards are vital tools for prototyping circuits. Inside the breadboard there are electrical connections between certain sockets. Power rails— columns on the left and the right of the breadboard — are electrically connected vertically, while terminal rows— rows in the middle of the breadboard — are connected horizontally (note that connections do not continue across the center notch in the breadboard).

![image of breadboard]()

You can read a tutorial about breadboards to learn more.

Build the LED Circuit

Each of the experiments in this guide will have a wiring diagram. They’ll show you where to plug in components and how to connect them to your Tessel 2.

![alt text]()

Having a hard time seeing the circuit? Click on the wiring diagram for a closer look.

- Plug the LED into the breadboard, taking care to plug the cathode into row 1 and the anode into row 2. Make sure not to plug it in backward!

- Connect a 100Ω resistor between the LED’s cathode and ground as shown, spanning the notch in the middle of the breadboard.

- Use jumper wires to connect the breadboard’s components to the Tessel 2: connect ground (row 1) to the Tessel 2’s Port A GND pin and source (row 2) to the Tessel 2’s Port A, Pin 5.

Using Johnny-Five to Make an LED Blink

Open your favorite code editor, create a file called led.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your led.js file:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var led = new five.Led("a5");

led.blink(500);

});

Now for the big reveal! Type — or copy and paste — the following into your terminal:

t2 run led.js

You terminal will display something like this:

![alt text]()

And when the program starts up:

![alt text]()

What You Should See

Your LED should be blinking:

Exploring the Code

Let’s take a deeper look at what’s going on in the led.js Johnny-Five code.

Requiring Modules

In Node.js, a program can use any number of code modules. Modules are independent chunks of functionality. The software functionality for Tessel and Johnny-Five is contained within modules. We need to tell Node.js to require those modules so that they are available to the program:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

Note: For Node.js to be able to find and use the modules, you need to use npm to install for the project. That happened when you set up your working environment—you used npm install to install both the tessel-io and johnny-five modules.

Instantiating Objects

Next, the code needs to instantiate (create) a new object that represents the Tessel 2 board, and assign it to a variable (board) so we can access it later:

language:javascript

var board = new five.Board({

io: new Tessel()

});

This creates a new instance of a Johnny-Five Board.

Johnny-Five supports many kinds of development boards. The support for some boards is built right in to Johnny-Five, but others — including Tessels — rely on external plugins encapsulated in modules. That’s why the code requires the tessel-ionpm module. Here, we tell Johnny-Five to use a Tessel object for IO when communicating with the board.

Learn more: Working with JavaScript Objects

Listening for Events

JavaScript code statements are typically executed top to bottom, in order, until they’re “done” (the program runs to completion) and nothing is left to do. One of Node.js' great powers is to allow programmers to “schedule” things to happen outside of this simple sequential-then-done flow. A program will terminate if there’s nothing left to do, but there are a number of ways to give the program something to do so that it keeps running.

Because the Tessel 2 board initialization involves hardware and I/O, it takes a few moments—considerably longer than the rest of the led.js script would take to execute. The initialization of the board won’t get in our program’s way—it happens asynchronously, allowing our script to keep executing statements without blocking—but we need to schedule something to happen when the board is ultimately ready.

language:javascript

board.on("ready", function() {

// ...this will execute when the board emits the `ready` event

});

The code snippet defines a function that will get executed when (‘on’) the board emits the ready event.

Next we need to fill in what that function should do when the board is ready to go.

Learn more: In-depth: JavaScript’s Concurrency Model and Event Loop

Blinking the LED

Once the board is ready, it’s time to configure an LED on Port A, Pin 5 and then tell that LED to blink. In Johnny-Five, that looks like this:

language:javascript

board.on("ready", function() {

var led = new five.Led("a5");

led.blink(500);

});

Instances of Johnny-Five’s Led class have some handy tools (attributes and methods) for doing LED things—for example, blink..

This code creates a new Led object and tells it what pin to use (in this case "a5"). Then it tells the LED to blink every 500 milliseconds (half a second). That means the LED will cycle 500ms off, then 500ms on.

Comparing Node.js + Johnny-Five With Arduino Sketches

The structure of Node.js scripts written with Johnny-Five differs from how Arduino sketches are written in the Arduino Programming Language. The following is an example sketch in the Arduino Programming Language that would make an LED blink on and off (assuming that LED was connected to pin 13 of a theoretical board):

language:cpp

void setup() {

pinMode(13, OUTPUT); // Set up pin 13 as an OUTPUT pin

}

void loop() {

digitalWrite(13, HIGH); // turn the LED on (HIGH puts voltage on the pin)

delay(500); // wait for a half second

digitalWrite(13, LOW); // turn the LED off by making the voltage LOW

delay(500); // wait for a half second

}

Arduino sketches have two sections:

setup: runs once and is a place for configuring pins and initializing stuffloop: runs over and over and over and over

Another thing you’ll notice is that Arduino code is lower-level, meaning that there are fewer abstractions of specific hardware details. Instead of having an LED object that can do LED-like things (blink, pulse, fade, etc.), you interact directly with the digital pin and write LOW and HIGH states to it.

Between those digital writes, you tell everything to stop and wait for 500 milliseconds (delay). And the thing about delay is: it stops everything. It’s a process-blocking operation. Nothing else can happen while delay, well, delays.

In terms of code complexity, the difference between Johnny-Five and the Arduino Programming Language isn’t too significant when you’re just blinking an LED, but when it comes to pulsing an LED, Arduino sketch code starts getting more complicated.

Pulsing an LED

Now that we’ve covered the basics and some of the lower level technical aspects of Johnny-Five, let’s write a program that pulses the LED. Instead of blinking the LED on and off, pulsing fades the LED smoothly from off to on, and then from on to off again.

Pulse Width Modulation (PWM)

The state of a digital output pin can only be one of two things: LOW or HIGH. That means, at any given exact moment, an LED connected to the pin can only be off or on. We fool the eye into thinking an LED is dimmed to, say, half brightness by using a technique called Pulse Width Modulation (PWM)

With PWM, the pin can be switched between HIGH and LOW very quickly, causing the LED turn on and off, too. This cycle between on and off happens too fast for the human eye to discern. The percentage of time that the pin (with the LED attached) is HIGH (on) over a given period is its duty cycle. A 30 percent duty cycle (on — or HIGH — 30% of the time) will make an LED look like it’s partially lit — dimmer than bright but definitely on. By adjusting the duty cycle over time, we can fake (very convincingly!) an LED fading on and off.

Only certain pins on development boards support PWM. On the Tessel 2, pins 5 and 6 on both ports (A and B) support PWM.

Pulsing an LED With Arduino

Pulsing an LED in an Arduino sketch (Arduino Programming Language) requires more effort than blinking. Much has changed here from the blinking sketch, but certain things remain the same. There is still a process-blocking operation (delay), this time for 30ms on each loop cycle. We can no longer use the digitalWrite() function (it can only write binary LOW or HIGH); instead we’ll need the analogWrite() function for writing PWM values from 0 (0% duty cycle) to 255 (100% duty cycle). There are also now three variables to keep track of: led for the pin number, brightness to track the present brightness state, and lastly fadeAmount which holds the increase or decrease value to be applied to the value of brightness. Whew!

Here’s what that looks like all together:

language:cpp

int led = 9; // the PWM pin the LED is attached to

int brightness = 0; // how bright the LED is

int fadeAmount = 5; // how many points to fade the LED by

void setup() {

pinMode(led, OUTPUT);

}

void loop() {

analogWrite(led, brightness);

brightness = brightness + fadeAmount;

if (brightness == 0 || brightness == 255) {

fadeAmount = -fadeAmount ;

}

delay(30);

}

It may be hard to get your head around the logic in that program. It’s not that easy to read. It doesn’t scream “pulse an LED” in the way that it expresses itself, does it?

Pulsing an LED With Johnny-Five

Let’s see what pulsing an LED looks like in Johnny-Five. Open your led.js script again. You’ll need to edit one line. Change the line that currently reads:

led.blink(500);

to

led.pulse(500);

No kidding—that’s it! No need to keep track of things, handle scheduling and timing or do arithmetic—instances of Johnny-Five’s Led do it all for you. Like blink, the pulse method takes an argument that is the pulse period in milliseconds. Here is the complete script for your copying-and-pasting convenience:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", function() {

var led = new five.Led("a5");

led.pulse(500);

});

Remember, to run the script and see your LED pulse, type — or copy and paste — the following command in a terminal:

t2 run led.js

What You Should See

Your LED should be pulsing in 500ms period cycles.

Building Further

Try adjusting the speed passed to the led.blink() and led.pulse() calls. For example: led.blink(1000) or led.pulse(1000) would change the cycles to 1000ms periods.

Reading Further

Experiment 2: Multiple LEDs

Introduction

In Experiment 1 of the Johnny-Five Inventor’s Kit (J5IK), you learned how to blink and pulse a single LED with a Tessel 2. In this experiment, you’ll learn how to control multiple, colorful LEDs with Johnny-Five to create animated variations on a simple “Cylon effect.” This article dives into structuring looping logic for your projects using Johnny-Five and JavaScript fundamentals.

Suggested Reading

The following tutorials provide in-depth background on some of the hardware concepts in this experiment:

- What is a Circuit?– This tutorial will explain what a circuit is, as well as discuss voltage in further detail.

- Voltage, Current, Resistance, and Ohm’s Law– Learn the basics of electronics with these fundamental concepts.

- LEDs (Light-Emitting Diodes)– LEDs are found everywhere. Learn more about LEDs and why they are used in so many products all over the world.

- Resistors– Why use resistors? Learn more about resistors and why they are important in circuits like this one.

- Polarity– Polarity is a very important characteristic to pay attention to when building circuits.

Parts Needed

You will need the following parts for this experiment:

- 1x Tessel 2

- 1x Breadboard

- 6x LEDs (One of each color: red, orange, yellow, green, blue, purple)

- 6x 100Ω Resistor

- 7x Jumper Wires

Using a Tessel 2 without the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

24In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

PRT-12795

These are 6" long jumper wires with male connectors on both ends. Use these to jumper from any female header on any board, to…

1In stock

DEV-13841

The Tessel 2 is a development board with on-board WiFi capabilities that allows you to build scripts in Node.js. This Tessel …

In stock

COM-13761

These are 1/4th Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 100 Ohm resistors m…

Hardware Hookup

Its now the fun part! It’s time to start building your circuit. Let’s take a look at what goes into building this circuit.

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

Build the Multiple-LED Circuit

![alt text]()

Having a hard time seeing the circuit? Click on the wiring diagram for a closer look.

- Connect the LEDs to the breadboard. Make sure to connect their cathode legs to sockets in the ground column in the power rail.

- Plug in the 100Ω resistors in terminal rows shared with the anode legs of the LEDs, spanning the central notch.

- Connect jumper wires between the resistors and the Tessel 2. You may find it helpful to use colors that correspond to the LED’s color.

- Use a jumper wire to connect the ground power rail of the breadboard to the Tessel 2’s GND pin.

Lighting Up LEDs Side-to-Side

Open your favorite code editor, create a file called side-to-side.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your side-to-side.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var leds = new five.Leds(["a2", "a3", "a4", "a5", "a6", "a7"]);

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off();

leds[index].on();

index += step;

if (index === 0 || index === leds.length - 1) {

step *= -1;

}

});

});

Before you run this on your Tessel 2, pause for a moment. Can you tell what the program will do?

Type – or copy and paste – the following command into your terminal and press enter:

t2 run side-to-side.js

Once the program starts up, your multiple-LED circuit should light up in a pattern like this:

Exploring the Code

Before continuing, we recommend that you’ve read Experiment 1: Exploring the Code.

The side-to-side program lights up LEDs in the following pattern:

- From lowest pin number to highest pin number, turn on one LED at a time every 100 milliseconds, then:

- From highest pin number to lowest pin number, turn on one LED at a time every 100 milliseconds, then:

- Repeat from step 1.

Collections of LEDs With the Leds Class

Instead of instantiating each LED as its own object separately using the Led class (as we did in Experiment 1), we can create a single collection that contains all of the LEDs in one swoop:

language:javascript

board.on("ready", function() {

var leds = new five.Leds(["a2", "a3", "a4", "a5", "a6", "a7"]);

});

Johnny-Five’s Leds constructor takes an Array of pin numbers and creates an Led object for each of them. Each of these Led objects can be accessed and manipulated from the container-like leds object. Instances of the Leds class behave like Arrays but have some extra goodies (they’re described as “Array-like objects”).

Read up on JavaScript Arrays if the concept is new or you’re feeling rusty.

Looping in Johnny-Five

To turn on LEDs one at a time, we need some way of creating a loop that executes every 100 milliseconds. We’re in luck. Board object instances have a loop method that can do just that! Convenient!

language:javascript

board.on("ready", () => {

board.loop(100, () => {

// ... This function gets invoked every 100 milliseconds

});

});

The function (in this case, an arrow function]) passed as the second argument to loop will get invoked every 100 milliseconds. Now, let’s see what needs to happen in that loop.

Lighting Up, Lighting Down

Here’s what we need to accomplish in each invocation of the loop callback function:

language:javascript

board.on("ready", () => {

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off(); // 1. Turn all of the LEDs off

leds[index].on(); // 2. Turn on the "next" active LED

// ... // 3. Determine what the next active LED will be

});

});

In step one, all LEDs are turned off. Leds instances have an off method that will turn off every Led in its collection. Easy peasy.

The variable index holds the index of the next LED that should get turned on. The initial value of index is 0. Why 0? Each Led in leds can be accessed by its numeric index, like an Array:

| Reference | LED |

|---|

leds[0] | Led object controlling red LED on Port A, Pin 2 |

leds[1] | Led object controlling red LED on Port A, Pin 3 |

leds[2] | Led object controlling red LED on Port A, Pin 4 |

leds[3] | Led object controlling red LED on Port A, Pin 5 |

leds[4] | Led object controlling red LED on Port A, Pin 6 |

leds[5] | Led object controlling red LED on Port A, Pin 7 |

The first time the loop executes, index is 0, and it will turn on leds[0], which is the first (red) LED on Port A, Pin 2:

language:javascript

leds[index].on();

Step 3 sets us up for the next time the loop function executes. The value of index needs to be set to the index of the next LED that should turn on. This is what the step variable helps us with. Add step to index to get the index of the next LED to light up:

language:javascript

board.on("ready", () => {

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off(); // 1. Turn all of the LEDs off

leds[index].on(); // 2. Turn on the "next" active LED

index += step; // 3a. Add `step` to index

});

});

At the completion of the first invocation of the loop callback function, index will hold the value 1.

During the second invocation, the second, orange LED (leds[1]) will light up. index will be incremented to 2.

And so on, lighting up red, orange, yellow, green, blue … But then we get to the purple LED (Port A, Pin 7) at index 5. There is no Led element at leds[6], so what do we do now? Well, we can flip the sign of step, changing its value to -1:

language:javascript

board.on("ready", () => {

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off(); // 1. Turn all of the LEDs off

leds[index].on(); // 2. Turn on the "next" active LED

index += step; // 3a. Add `step` to index

if (index === leds.length - 1) { // 3b. If we're at the highest index...

step *= -1; // ...invert the sign of step

}

});

});

Now invocations of the loop callback function will decrease (decrement) the index value, and the LEDs will light up in reverse order. When the index gets down to 0— the first LED — we need to swap the sign of step again:

language:javascript

board.on("ready", () => {

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off(); // 1. Turn all of the LEDs off

leds[index].on(); // 2. Turn on the "next" active LED

index += step; // 3a. Add `step` to index

// If we are at the lowest OR the highest index...

if (index === 0 || index === leds.length - 1) {

step *= -1;

}

});

});

Using board.loop with the leds can be adapted in various ways to change the way the LEDs light up. Let’s try a few variations.

Variation: One-by-One On, One-by-One Off

Now we’ll light up each LED one at a time and keep them on as we go; the display will loop as:

- From lowest pin number to highest pin number, turn on each LED and keep it on.

- From highest pin number to lowest pin number, turn off each LED and keep it off.

- Repeat from step 1.

Open your favorite code editor, create a file called one-by-one-on-off.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your one-by-one-on-off.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var leds = new five.Leds(["a2", "a3", "a4", "a5", "a6", "a7"]);

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off().slice(0, index).on();

index += step;

if (index === 0 || index === leds.length) {

step *= -1;

}

});

});

All of the changes are confined to the loop callback function. There’s one line doing much of the heavy lifting here:

leds.off().slice(0, index).on();

This single line turns all of the LEDs off and then turns on all LEDs between 0 and the current index. slice is an Array method that returns a chunk of an array between the start and end indexes provided (leds isn’t an Array, remember, but it acts like one, so it also has a slice method).

As in the previous example, this script will flip the sign on step when it reaches either end of the leds collection.

Run the script by typing – or copying and pasting – the following command in your terminal:

t2 run one-by-one-on-off.js

Once the program starts up, your LEDs circuit should display something like this:

Variation: One-by-One On, Clear and Repeat

Now let’s simplify that same program: light up each pin, one at a time, and then turn them off; the display will loop as:

- From lowest pin number to highest pin number, turn on each LED and keep it on.

- Once all the LEDs are on, turn them all off

- Repeat from step 1.

Open your favorite code editor, create a file called one-by-one-clear-repeat.js and save it in the j5ik/ directory. Type – or copy and paste – the following JavaScript code into your one-by-one-clear-repeat.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var leds = new five.Leds(["a2", "a3", "a4", "a5", "a6", "a7"]);

var index = 0;

board.loop(100, () => {

if (index === leds.length) {

leds.off();

index = 0;

} else {

leds[index].on();

index++;

}

});

});

Again, there is very little to change here, so we’ll skip right to the operations within the call to board.loop(...).

language:javascript

board.loop(100, () => {

if (index === leds.length) {

leds.off();

index = 0;

} else {

leds[index].on();

index++;

}

});

The semantics for this program are slightly different from the previous examples. Because we’re always lighting LEDs up in the same direction — lowest to highest index — we don’t have to deal with the logic for swapping the sign on a step variable. Instead, a simple increment of the index value on each invocation of the loop callback function is all we need, resetting it to 0 when we run out of LED indexes.

- If the

index equals the number of LEDs in the leds collection, - Turn all

ledsoff. - Set the

index back to 0. - Else,

- Turn the

led at present indexon. - Increment the

index.

Type — or copy and paste — the following into your terminal:

t2 run one-by-one-clear-repeat.js

Once the program starts up, your LEDs circuit should display something like this:

Variation: Collision

Changing gears a bit, this next program will light LEDs from the middle, out, and back (there will be two LEDs lit at a time); the display will loop as:

- From the first to the last and the last to the first, by pin number, light the LEDs one at a time.

- Repeat from step 1.

Open your favorite code editor, create a file called collision.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your collision.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var leds = new five.Leds(["a2", "a3", "a4", "a5", "a6", "a7"]);

var index = 0;

var step = 1;

board.loop(100, () => {

leds.off();

leds[index].on();

leds[leds.length - index - 1].on();

index += step;

if (index === 0 || index === leds.length - 1) {

step *= -1;

}

});

});

This example contains logic more in line with the first few variations again — turning on the correct LED and then determining what the next LED’s index will be:

- Turn all

ledsoff. - Turn the

leds at index and its counterpart on. - Update the

index with step (either 1 or -1). - If

index equals 0, or index equals the number that corresponds to the last possible led in the leds collection, flip the sign of step.

Type — or copy and paste — the following into your terminal:

t2 run collision.js

Once the program starts up, your LEDs circuit should display something like this:

Building Further

- Try writing your own algorithms for other patterns not shown here.

Reading Further

- JavaScript– JavaScript is the programming language that you’ll be using:

- Node.js– Node.js is the JavaScript runtime where your programs will be executed.

- Johnny-Five– Johnny-Five is a framework written in JavaScript for programming hardware interaction on devices that run Node.js.

Experiment 3: Reading a Potentiometer

Introduction

So far the experiments have been focused on output: writing code with Johnny-Five to control the state of one or more LEDs. In this experiment, you’ll learn how to read analog input data from a potentiometer. You’ll learn about how development boards (like the Tessel 2) sample and process analog input and how to use data from analog sources to make things happen. Using data from the potentiometer, you’ll control a bar graph in your terminal, alter the brightness of an LED and control the activity of multiple LEDs.

Suggested Reading

The following tutorials provide in-depth background on some of the hardware concepts in this experiment:

Parts Needed

You will need the following parts for this experiment:

- 1x Tessel 2

- 1x Breadboard

- 1x Potentiometer

- 1x Standard LED (any color)

- 1x 100Ω Resistor

- 7x Jumper Wires

Using a Tessel 2 without the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

24In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

6In stock

PRT-12795

These are 6" long jumper wires with male connectors on both ends. Use these to jumper from any female header on any board, to…

1In stock

DEV-13841

The Tessel 2 is a development board with on-board WiFi capabilities that allows you to build scripts in Node.js. This Tessel …

In stock

COM-13761

These are 1/4th Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 100 Ohm resistors m…

Introducing Potentiometers

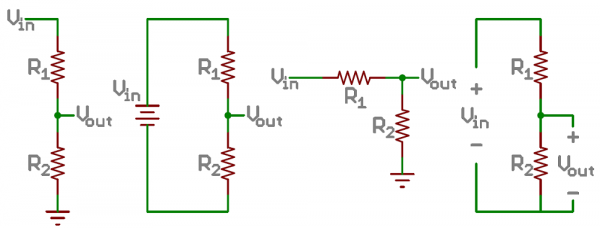

A potentiometer is a resistance-based analog sensor that changes its internal resistance based on the rotation of its knob. The potentiometer has an internal voltage divider, creating a varying voltage on the center pin. The voltage on the center pin changes as the knob is turned. You can use an analog input pin to read this changing voltage.

![alt text]()

Hardware Hookup

Its now the fun part! It’s time to start building your circuit. Let’s take a look at what goes into building this circuit.

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

Build the Potentiometer Circuit

To hook up the potentiometer, attach the two outside pins to a supply voltage (3.3V in this circuit) and ground. It doesn’t matter which is connected where, as long as one is connected to power, and the other to ground. The center pin is then connected to an analog input pin so the Tessel 2 can measure changes in voltage as the knob is turned.

Note: The potentiometer included in the kit has three marks on it that will help you figure out which breadboard rows the pins are plugged into.

![alt text]()

Having a hard time seeing the circuit? Click on the wiring diagram for a closer look.

- Connect the potentiometer to the breadboard. Connect the potentiometer’s power pins (supply and ground) to the power rail with jumper wires and connect the middle pin to the Tessel 2’s Port A, Pin 7.

- Connect the LED. Use a jumper wire to connect the Tessel 2’s Port B, Pin 5 through the 100Ω resistor and to the LED’s anode (positive, longer) leg. Connect the LED’s cathode to ground on the power rail. Double-check the legs on the LED to make sure you haven’t plugged it in backward!

- Use jumper wires to connect the Tessel 2’s 3.3V and GND pins to the breadboard’s power rails.

Reading Analog Sensors With Johnny-Five

Open your favorite code editor, create a file called sensor-basic.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your sensor-basic.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel(),

repl: false,

debug: false,

});

board.on("ready", () => {

var sensor = new five.Sensor("a7");

sensor.on("change", () => console.log(sensor.value));

});

Note: For programs that output a lot of data quickly to the terminal such as this one, we recommend deploying your code over LAN for best results.

To Deploy Code Over WiFi:- Connect your Tessel to the same Wifi network as your computer t2 wifi -n[SSID] -p[PASSWORD]`

- Make sure that your Tessel is provisioned and shows up in your list of Tessels using t2 list. See the Hardware Installation and Setup for how to provision your Tessel if it doesn't show up in your list.

- Deploy your code using the

--lan tag. Example:t2 run mycode.js --lan

Type — or copy and paste — the following into your terminal:

t2 run sensor-basic.js

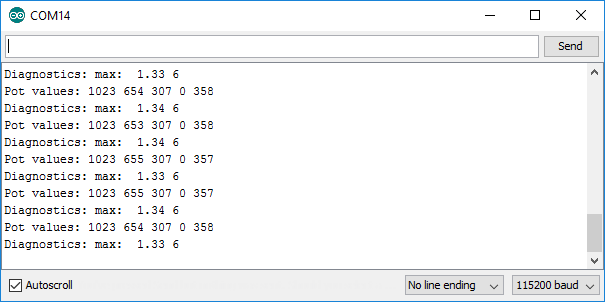

This isn’t particularly interesting, as all it does is output the value of the sensor (integers between 0 and 1023) until the program is interrupted. yawn

![alt text]()

You should see something similar to this. Your sensor values (0-1023) being logged in the console.

Exploring the Hardware

Analog Input

For software to be able to work with data coming from an analog sensor, it first needs to be converted from an analog signal (infinite possible values) to a digital signal (discrete set of values). The microcontroller on the Tessel 2 does this analog-to-digital conversion (ADC) for you, sampling the incoming analog voltages and converting them to a range of values between 0 (0V) and 1023 (3.3V). Values in between are quantized to the nearest integer.

Asynchronous I/O

In Experiment 1: Blink an LED, we looked at the asynchronous nature of Node.js runtime, comparing how the Arduino Programming Language’s delay function is blocking, while Johnny-Five’s execution model follows the Node.js convention: non-blocking. Listening for Boardready events is an example of a common asynchronous pattern. Non-blocking I/O is extremely important to the JavaScript-for-hardware story, and the Tessel 2 has an exemplary implementation.

Tessel 2’s support for asynchronous, non-blocking I/O is in its hardware. In addition to the Mediatek chip (that’s where your code executes), it has a second processor (Atmel® SAMD21) that is responsible for I/O.

The MediaTek processor and the Atmel coprocessor exchange messages representing I/O state. Code that executes on the MediaTek chip (the Linux user space) has asynchronous access to the state captured on SAMD21. For example, if a digital input pin goes HIGH, the SAMD21 sends a message to the MediaTek chip and any code running can elect to consume that message. When code running on the MediaTek chip wants to output values to the SAMD21 to be written to an output pin, it simply sends the message, then keeps going.

![alt text]()

The MediaTek chip (green) and the Atmel SAMD21 (blue) allow for Asynchronous I/O on your Tessel 2.

For the purpose of our experiment, it’s helpful to understand that when program code running on the MediaTek chip wants to know the value of an analog input, it sends a request for that information, registers a handler (a function) and continues on. Sometime “later” (likely within a millisecond or two), and always in a different execution turn, the SAMD21 responds with the present value of the input. The registered handler is then invoked with response value. This may happen once or repeatedly, but never causes the program to stop and wait.

Exploring the Code

Notice that the Board constructor call is being passed an object with two properties that we haven’t seen before: repl: false and debug: false. These settings tell Johnny-Five to shut off both the “on-by-default” REPL (Read–Eval–Print Loop, an interactive prompt) and connection debugging output.

Once the board has emitted the ready event, hardware inputs are ready for interaction:

language:javascript

var sensor = new five.Sensor("a7");

The first thing to do is create an instance of the Sensor class, indicating that this sensor is attached to Port A, Pin 7.

language:javascript

sensor.on("change", () => console.log(sensor.value));

Then, a handler function is registered for change events, meaning that anytime the reading changes, the function will be called.

Every time this function is called and the sensor value is displayed, it occurs in a different execution turn than the previous invocation, staying true to the asynchronous, non-blocking model. The handler function for change events simply logs sensor.value. sensor.value is a 10-bit number (0-1023), representing the last successful ADC-processed read from the Sensor object’s associated analog input pin.

Note: The minimum version of Node.js that runs on Tessel 2 supports many ES2015 features, including Arrow Functions, so we’re using those here to simplify the program.

Variation: Sensor Input Graphing

For this experiment, you will be “bar chart graphing” light intensity values in your terminal using the Barcli module:

![barcli]()

barcli [bahrk-lee]

Barcli is a simple tool for displaying real-time data in the console. Multiple instances of Barcli can be stacked to show multiple axes, sensors or other data sources in an easy-to-read horizontal bar graph.

In your terminal, make sure you’re inside the working directory (j5ik), then type — or copy and paste — the following command:

npm install barcli

We’ll make our sensor data a little more interesting (than just numbers scrolling by). Let’s visualize it as a graph displayed directly in the terminal. Open your favorite code editor, create a file called sensor-graph.js and save it in the j5ik/ directory.

Type — or copy and paste — the following JavaScript code into your sensor-graph.js file:

language:javascript

var Barcli = require("barcli");

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", function() {

var range = [0, 100];

var graph = new Barcli({

label: "My Data",

range: range,

});

var sensor = new five.Sensor({

pin: "a7",

threshold: 5 // See notes below for detailed explanation

});

sensor.on("change", () => {

graph.update(sensor.scaleTo(range));

});

});

Note: For programs that output a lot of data quickly to the terminal such as this one, we recommend deploying your code over LAN for best results.

To Deploy Code Over Wifi:- connect your Tessel to the same Wifi network as your computer t2 wifi -n[SSID] -p[PASSWORD]`

- Make sure that your Tessel is provisioned and shows up in your list of Tessels using t2 list, see Hardware Installation and Setup for how to provision your Tessel if it doesn't show up in your list.

- Deploy your code using the

--lan tag. Example:t2 run mycode.js --lan

Type — or copy and paste — the following into your terminal:

t2 run sensor-graph.js

Once the program starts up, the terminal should display something like this:

![alt text]()

Exploring the Code

We’ve now required the Barcli module:

language:javascript

var Barcli = require("barcli");

… which means it can be put to use in your program.

To create a graph, we’ll need an instance of a Barcli object. First, though, we need to define a range of values that are valid for the graph:

language:javascript

var range = [0, 100];

var graph = new Barcli({

label: "My Data",

range: range,

});

The graph object is now able to represent values from 0 to 100. However, recall that values coming from the potentiometer will range from 0 to 1023. We’ve got to scale those, too, so that they can be graphed!

The way we’re instantiating the Sensor object looks a bit different from the previous example. Instead of passing the constructor a String identifying the pin, like so:

language:javascript

var sensor = new five.Sensor("a7");

… we’re using the options object form here, which allows us to pass a whole object full of extra information to the constructor:

language:javascript

var sensor = new five.Sensor({

pin: "a7",

threshold: 5

});

Let’s talk about that threshold property. It defines how much a sensor’s value needs to change before a change event is emitted. The default value of threshold is 1. As you saw in the first example, any change to the sensor’s value – remember, values range from 0 to 1023 and are whole numbers (integers) – will cause a change event. For this variation, that’s too much sensitivity.

Specifically, we want to define a threshold that will limit the change events to those that are relevant to our range, which is 0-100. Since we’ll be scaling the sensor’s value from 0-1023 to 0-100, we only care about changes of approximately every 10 steps in 1023 (obviously that’s fudging a little, and you’re encouraged to be more precise in your actual programs). The threshold value is exactly half of the approximate step:

> (value + 5)< (value - 5)

Finally, the program replaces the call to console.log(...) with a call to graph.update(...) and passes the result of calling the sensor object’s scaleTo(...) method with the same range as graph is using:

language:javascript

sensor.on("change", () => {

graph.update(sensor.scaleTo(range));

});

Unpacking the line:

language:javascript

graph.update(sensor.scaleTo(range));

When invocations are nested like this, they proceed from the inside out. First, the sensor object’s 10-bit value is scaled to 0-100 (range) and then that resulting value is passed to the graph object’s update method.

Variation: Using Sensor Input to Create Output

For the final variation of this experiment, you’ll process the sensor readings to control the brightness of the LED in your circuit. Open your favorite code editor, create a file called sensor-input-to-output.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your sensor-input-to-output.js file:

language:javascript

var five = require("johnny-five");

var Tessel = require("tessel-io");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", function() {

var sensor = new five.Sensor({

pin: "a7",

threshold: 2

});

var led = new five.Led("b5");

sensor.on("change", () => {

led.brightness(sensor.scaleTo(0, 255));

});

});

Type — or copy and paste — the following into your terminal:

t2 run sensor-input-to-output.js

Once the program starts up, LED should display something like this:

Exploring the Code

Again, we’re instantiating a Sensor object to represent the potentiometer, and defining a threshold. This time we’ll set it to 2, because the rounded result of 1023 (the top of the 10-bit sensor range) divided by 255 (the top of the 8-bit brightness range) is 4, and threshold should be set to half of the full step size:

language:javascript

var sensor = new five.Sensor({

pin: "a7",

threshold: 2

});

Next, a new instance of the Led class is created, with Pin 5 on Port B:

language:javascript

var led = new five.Led("b5");

+The change event remains the same, but the operation within the handler is updated to call the led object’s brightness(...) method, passing the sensor’s value scaled from its 10-bit input range (0-1023) to the 8-bit output range (0-255) of the led:

language:javascript

sensor.on("change", () => {

led.brightness(sensor.scaleTo(0, 255));

});

Alternatively, the conversion could have been written as a bit-shifting operation, where the 10-bit value is shifted 2 bits to the right, since brightness(...) expects an 8-bit value (0-255). This bit-shifting operation is the most efficient way to scale the 10-bit analog input value to the 8-bit PWM output value:

language:javascript

0b1111111111 === 1023;

0b0011111111 === 255;

0b11111111 === 255;

(0b1111111111 >> 2) === 255;

And could be applied in our code like so:

language:javascript

sensor.on("change", () => {

led.brightness(sensor.value >> 2);

});

This snippet means “shift the sensor.value 2 bits to the right” — the two right-most bits are discarded. Voila! An 8-bit number from a 10-bit number.

Building Further

- Experiment with bit shifting in your Node.js console.

Reading Further

- JavaScript– JavaScript is the programming language that you’ll be using:

- Node.js– Node.js is the JavaScript runtime where your programs will be executed.

- Johnny-Five– Johnny-Five is a framework written in JavaScript for programming hardware interaction on devices that run Node.js.

Introduction

In Experiment 3, you journeyed into the fun world of input by reading data from an analog sensor. This experiment continues that journey, moving now into digital input. You’ll learn how digital input differs from analog input, and you’ll meet a useful new component: the push button (also sometimes called a momentary switch). You’ll learn how to control a single LED with button presses, and then how to control multiple LEDs from multiple buttons.

Suggested Reading

The following tutorials provide in-depth background on some of the hardware concepts in this experiment:

Parts Needed

To complete this experiment, you’ll build two circuits. You’ll need the following parts:

- 1x Tessel 2

- 1x Breadboard

- 2x Standard LED (any color is fine)

- 2x Push Button

- 2x 100Ω Resistors

- 2x 10kΩ Resistors

- 12x Jumper Wires

Using a Tessel 2 without the kit? No worries! You can still have fun and follow along with this experiment. We suggest using the parts below:

In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

24In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

COM-09190

This is a standard 12mm square momentary button. What we really like is the large button head and good tactile feel (it 'clic…

4In stock

PRT-12795

These are 6" long jumper wires with male connectors on both ends. Use these to jumper from any female header on any board, to…

1In stock

DEV-13841

The Tessel 2 is a development board with on-board WiFi capabilities that allows you to build scripts in Node.js. This Tessel …

In stock

COM-11508

1/6th Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 10K resistors make excellent …

In stock

COM-13761

These are 1/4th Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and perf boards, these 100 Ohm resistors m…

Introducing the Push Button

![alt text]()

A momentary push button is a kind of switch, closing (completing) a circuit while it is being actively pressed. If you take a push button and look at it, you’ll notice it has four pins, which might seem like a lot of pins. Let’s walk through how the pins are connected to each other.

The four pins on a push button are split into two pairs. Each pin is adjacent to two other pins: the other half of its pair (on the opposite side of the button) and a pin not paired with it (located on the same side). A pin is always electrically connected to the other pin in its pair, but is only connected to the other adjacent pin when the button is actively being pressed. When you press down on the button and get a nice “click,” the button bridges the two sets of pins and allows current to flow through the circuit.

How do you know which pins are paired up? The buttons included in this kit will only fit across the breadboard ditch in one direction. Once you get the button pressed firmly into the breadboard (across the ditch), the pins are horizontally paired. The pins toward the top of the breadboard are connected, and the pins toward the button of the breadboard are connected.

Note: Not all buttons share this pin format. Please refer to the data sheet of your specific button to determine which pins are paired up.

All right, now we have a sense of how a button can complete a circuit, but we need the right kind of circuit for our button. Button presses need to cause a digital input on the Tessel to move between HIGH and LOW logic levels when the button is pressed. The circuits in the two wiring diagrams for this experiment use a 10kΩ pull-down resistor with the buttons to make sure that the Tessel will read the button circuit as LOW (off/false) when the button isn’t pressed and HIGH (on/true) when it is.

Hardware Hookup

Your kit comes with four different colored push buttons. All push buttons behave the same, so go ahead and use your favorite color!

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

Build the Button Circuit

![alt text]()

Having a hard time seeing the circuit? Click on the wiring diagram for a closer look.

- Connect the pushbutton to the breadboard. It should only fit in one orientation spanning the center notch. Use jumper wires to connect one of the right-hand pins of the button to the ground power rail, through a 10kΩ resistor, as shown. Connect the other pin of the right side of the button to the supply power rail with another jumper wire.

- Starting from a socket on the same row as the 10kΩ resistor — but on the opposite side of it from the button — connect a jumper wire to the Tessel’s Port A, Pin 0.

- Plug the LED into the breadboard as shown, making sure the anode (longer leg) is closer to the top of the breadboard. Connect the cathode (shorter leg) to the ground power rail using a jumper wire. Connect the anode, through a 100Ω resistor, to the Tessel 2’s Port A, Pin 5.

- Connect the Tessel’s +3.3V and GND pins to the breadboard’s power rails, using jumper wires.

Observing a Button With Johnny-Five’s Button Class

Open your favorite code editor, create a file called button.js and save it in the j5ik/ directory. Type — or copy and paste — the following JavaScript code into your button.js file:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", () => {

var button = new five.Button("a2");

button.on("press", () => console.log("Button Pressed!"));

button.on("release", () => console.log("Button Released!"));

});

Type — or copy and paste — the following into your terminal:

t2 run button.js

What You Should See

When you press the button, your terminal will display the appropriate message:

![alt text]()

Console output triggered by button events

Exploring the Code

Using Input to Control Output With Johnny-Five

OK, let’s make this do something a little more interesting before we dive in and look at how it works. Go back to your button.js and either type the changes or copy and paste the following code:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", function() {

var led = new five.Led("a5");

var button = new five.Button("a2");

button.on("press", () => led.on());

button.on("release", () => led.off());

});

Type — or copy and paste — the following into your terminal:

t2 run button.js –single

The --single flag tells the T2 CLI to only deploy the single, specified file. This will preserve all other existing code on the Tessel 2 while still deploying your new program changes, which can make the deployment faster.

What You Should See

When you press the button, the LED should light up. When you release the button, the LED should turn off.

Exploring the Code

Once the board has emitted the ready event, we can initialize Led and Button instances to interact with our hardware on the specified pins:

language:javascript

var led = new five.Led("a5");

var button = new five.Button("a2");

The Johnny-Five Button class takes care of processing values from input in order to emit intuitive events for each state of the hardware. We’ve registered handlers for these events: press, hold and release.

When the button is pressed, turn the LED on:

language:javascript

button.on("press", () => led.on());

When the button is released, turn the LED off:

language:javascript

button.on("release", () => led.off());

Note: The minimum version of Node.js that runs on Tessel 2 supports many ES2015 features, including Arrow Functions, so we’re using those here to simplify the program.

Variation: Using Complex Input to Control Output With Johnny-Five

Go back to your button.js and either type the changes or copy and paste the following code:

language:javascript

var Tessel = require("tessel-io");

var five = require("johnny-five");

var board = new five.Board({

io: new Tessel()

});

board.on("ready", function() {

var led = new five.Led("a5");

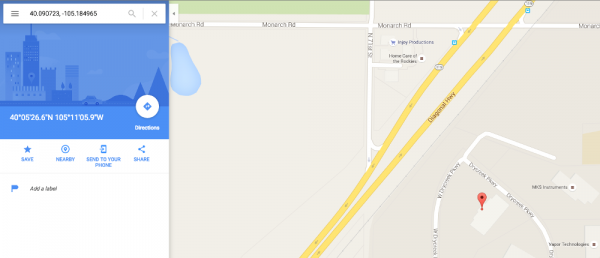

var button = new five.Button("a2");