Introduction

This SparkFun Tinker Kit is your map for navigating the waters of beginning embedded electronics, robotics and citizen science using the SparkFun RedBoard while sticking to a strict budget. This guide contains all the information you will need to explore the 11 circuits of the SparkFun Tinker Kit. At the center of this guide is one core philosophy – that anyone can (and should) play around with cutting-edge electronics in a fun and playful way while not breaking the bank.

When you’re done with this guide, you’ll have the know-how to start creating your own projects and experiments. From building robots and game controllers to data logging, the world will be your oyster. Now enough talking – let’s start tinkering!

SparkFun Tinker Kit

In stock

KIT-14556

The SparkFun Tinker Kit (STK) is a great way to get started with programming and hardware interaction with the Arduino progra…

Open Source!

At SparkFun, our engineers and educators have been improving this kit and coming up with new experiments for a long time now. We would like to give attribution to Oomlout, since we originally started working off their Arduino Kit material many years ago. The Oomlut version is licensed under the Creative Commons Attribution Share-Alike 3.0 Unported License.

The SparkFun Tinker Kit is licensed under the Creative Commons Attribution Share-Alike 4.0 International License.

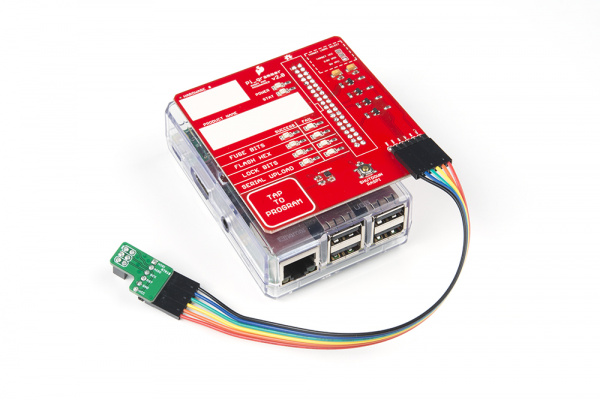

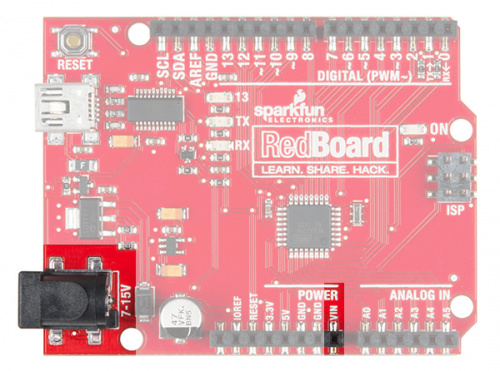

The SparkFun RedBoard

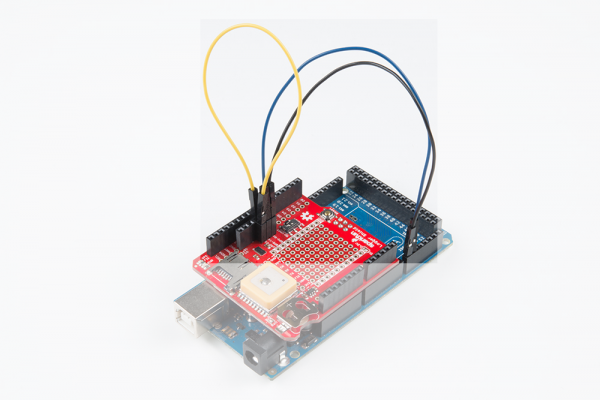

The SparkFun RedBoard is your development platform. At its roots, the RedBoard is essentially a small, portable computer, also known as a microcontroller. It is capable of taking inputs (such as the push of a button or a reading from a light sensor) and interpreting that information to control various outputs (like blinking an LED light or spinning an electric motor). That’s where the term “physical computing” comes in; this board is capable of taking the world of electronics and relating it to the physical world in a real and tangible way.

The SparkFun RedBoard is one of a multitude of development boards based on the ATmega328 microprocessor. It has 14 digital input/output pins (six of which can be PWM outputs), six analog inputs, a 16MHz crystal oscillator, a USB connection, a power jack, and a reset button. You’ll learn more about each of the RedBoard’s features as you progress through this guide.

Check out the guide below to learn more about the SparkFun RedBoard.

Understanding Breadboards

A breadboard is a circuit-building platform that allows you to connect multiple components without using a soldering iron.

If you have never seen or used a breadboard before, it is highly recommended you read the following guide that explains the breadboards anatomy and how to use one.

How to Use a Breadboard

Welcome to the wonderful world of breadboards. Here we will learn what a breadboard is and how to use one to build your very first circuit.

Install the Arduino IDE

The following steps are a basic overview of getting started with the Arduino IDE. For more detailed, step-by-step instructions for setting up the Arduino IDE on your computer, please check out the following tutorial.

Installing Arduino IDE

A step-by-step guide to installing and testing the Arduino software on Windows, Mac, and Linux.

Download the Arduino IDE

In order to get your microcontroller up and running, you’ll need to download the newest version of the Arduino software first (it’s free and open source!).

Download the Arduino IDE

This software, known as the Arduino IDE, will allow you to program the board to do exactly what you want. It’s like a word processor for writing code.

Connect the Microcontroller to your Computer

Use the USB cable provided in the kit to connect the included microcontroller (RedBoard or Arduino Uno) to one of your computer’s USB inputs.

Install FTDI Drivers

Depending on your computer’s operating system, you will need to follow specific instructions. Please go to How to Install FTDI Drivers, for specific instructions on how to install the FTDI drivers onto your RedBoard.

Select your Board: Arduino/Genuino Uno

Before we can start jumping into the experiments, there are a couple adjustments we need to make.

This step is required to tell the Arduino IDE which of the many Arduino boards we have. Go up to the Tools menu. Then hover over Board and make sure Arduino Uno is selected.

Please note: Your SparkFun RedBoard and the Arduino UNO are interchangeable but you won’t find the RedBoard listed in the Arduino Software. Select “Arduino/Genuino Uno” instead.

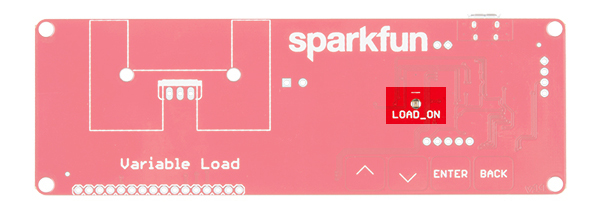

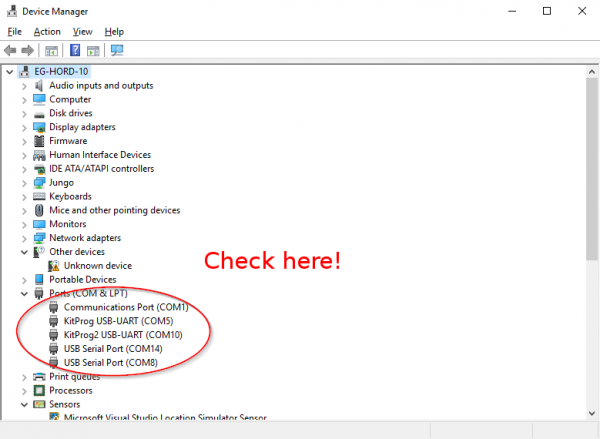

Select a Serial Port

Next up we need to tell the Arduino IDE which of our computer’s serial ports the microcontroller is connected to. For this, again go up to Tools, then hover over Port (Serial Port in older Arduino versions) and select your RedBoard or Arduino’s serial port. This will be the same serial port seen when installing FTDI drivers.

With that, you’re now ready to begin building your first circuit!

Circuit 1: Blink an LED

Light-Emitting Diodes, or LEDs (pronounced el-ee-dees), are small, powerful lights that are used in many different applications. You can find LEDs in just about any source of light nowadays, from the bulbs lighting your home to the tiny status lights flashing on your home electronics. Blinking an LED is the classic starting point for learning how to program embedded electronics. It’s the “Hello, World!” of microcontrollers.

In this circuit, you’ll write code that makes an LED flash on and off. This will teach you how to build a circuit, write a short program and upload that program to your RedBoard.

![Tinker Kit Circuit 1]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 1x Red LED

- 1x 330Ω Resistor

- 2x Jumper Wires

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

PRT-14490

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

New Components and Concepts: Each circuit will introduce new components or parts that will be used in the circuit. Each circuit will also introduce a few new concepts that will help you understand what your circuit and code is doing and why.

New Components

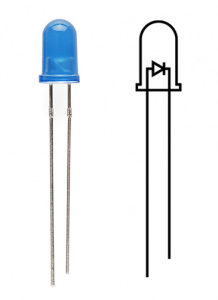

LED (Light Emitting Diode)

Light-Emitting Diodes (LEDs) are small lights made from a silicon diode. They come in different colors, brightnesses and sizes. LEDs have a positive (+) leg and a negative (-) leg, and they will only let electricity flow through them in one direction. LEDs can also burn out if too much electricity flows through them, so you should always use a resistor to limit the current when you wire an LED into a circuit.

![LED]()

Resistors

Resistors resist the flow of electricity. You can use them to protect sensitive components like LEDs. The strength of a resistor (measured in ohms) is marked on the body of the resistor using small colored bands. Each color stands for a number, which you can look up using a resistor chart.

![Resistors]()

New Concepts

Polarity

Many electronics components have polarity, meaning electricity can only flow through them in one direction. Components like resistors do not have polarity; electricity can flow through them in either direction. However, components like an LED that do have polarity only work when electricity flows through them in one direction.

Ohm’s Law

Ohm’s law describes the relationship between the three fundamental elements of electricity: voltage, resistance and current. This relationship can be represented by the following equation:

![Ohm's Law]()

Where

- V = Voltage in volts

- I = Current in amps

- R = Resistance in ohms (Ω)

This equation is used to calculate what resistor values are suitable to sufficiently limit the current flowing to the LED so that it does not get too hot and burn out.

Digital Output

When working with microcontrollers such as the RedBoard, there are a variety of pins to which you can connect electronic components. Knowing which pins perform which functions is important when building your circuit. In this circuit, we will be using what is known as a digital output. There are 14 of these pins found on the RedBoard and Arduino Uno. A digital output only has two states: ON or OFF. These two states can also be thought of as HIGH or LOW or TRUE or FALSE. When an LED is connected to one of these pins, the pin can only perform two jobs: turning the LED on and turning the LED off. We’ll explore the other pins and their functions in later circuits.

![Digital Pins]()

The 14 digital pins highlighted.

Hardware Hookup

We recommend familiarizing yourself with each of the components used in each circuit first.

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

Pay close attention to the LED. It is polarized. The negative side of the LED is the short leg, marked with a flat edge.

![LED drawing]()

Components like resistors need to have their legs bent into 90° angles in order to correctly fit the breadboard sockets.

![Bent resistor]()

Ready to start hooking everything up? Check out the circuit diagram and hookup table below, to see how everything is connected.

Circuit Diagram

Circuit Diagrams: SparkFun uses a program called

Fritzing to draw the circuit diagrams you see throughout this guide and throughout all of our online guides. Fritzing allows us to create diagrams that make it easier for you to see how your circuit should be built.

![Tinker Kit Fritzing Diagram Circuit 1]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

Hookup Tables: Many electronics beginners find it helps to have a coordinate system when building their circuits. For each circuit, you'll find a hookup table that lists the coordinates of each component and where it connects to the RedBoard, the breadboard, or both. The breadboard has a letter/number coordinate system, just like the game Battleship.

| Component | RedBoard | Breadboard | Breadboard |

|---|

| LED | | A1 LED ( - ) | A2 LED ( + ) |

330Ω Resistor

(orange, orange, brown) | | E2 | F2 |

| Jumper Wire | GND | E1 | |

| Jumper Wire | Digital Pin 13 | J2 | |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open Your First Sketch

Open the Arduino IDE software on your computer.

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 1: Blink an LED

Turns an LED connected to pin 13 on and off. Repeats forever.

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code

*/

void setup() {

pinMode(13, OUTPUT); // Set pin 13 to output

}

void loop() {

digitalWrite(13, HIGH); // Turn on the LED

delay(2000); // Wait for two seconds

digitalWrite(13, LOW); // Turn off the LED

delay(2000); // Wait for two seconds

}

What You Should See

The LED will flash on for two seconds, off for two seconds, then repeat. If it doesn’t, make sure you have assembled the circuit correctly and verified and uploaded the code to your board, or see the Troubleshooting section at the end of this section.

![Tinker Kit Circuit 1]()

Program Overview

- Turn the LED on by sending power to Pin 13.

- Wait 2 seconds (2000 milliseconds).

- Turn the LED off by cutting power to Pin 13.

- Wait 2 seconds (2000 milliseconds).

- Repeat.

One of the best ways to understand the code you just uploaded is to change something and see how it affects the behavior of your circuit. For this first circuit, try changing the number found in these lines of code: delay(2000);. What happens if you change both to 100? What happens if you change both to 5000? What happens if you change just one delay and not the other?

Onboard LED PIN 13: You may have noticed a second, smaller LED blinking in unison with the LED in your breadboard circuit. This is known as the onboard LED, and you can find one on almost any Arduino or Arduino-compatible board including the RedBoard. In most cases, this LED is connected to

digital pin 13 (D13), which is the same pin used in this circuit. This LED is useful for troubleshooting, as you can always upload the Blink sketch to see if that LED lights up. If so, you know your board is functioning properly. If you do not want this LED to blink with other LEDs in your circuits, simply use any of the other 12 digital pins (D0-D12).

![]()

Code to Note

Code to Note: The sketches that accompany each circuit introduce new programming techniques and concepts as you progress through the guide. The Code to Note section highlights specific lines of code from the sketch and explains them in further detail.

| Code | Description |

|---|

Setup and Loop:

void setup(){code to run once}&void loop(){code to run forever} | Every Arduino program needs these two functions. Code that goes in between the curly brackets of setup() runs once, then the code in between the loop() curly brackets runs over and over until the RedBoard is reset or powered off. |

Input or Output?:

pinMode(13, OUTPUT); | Before you can use one of the digital pins, you need to tell the RedBoard whether it is an INPUT or OUTPUT. We use a built-in "function" called pinMode() to make pin 13 a digital output. You'll learn more about digital inputs in Project 2. |

Digital Output:

digitalWrite(13, HIGH); | When you're using a pin as an OUTPUT, you can command it to be HIGH (output 5 volts) or LOW (output 0 volts). |

Delay:

delay(time in milliseconds); | Causes the program to wait on this line of code for the amount of time in between the brackets. After the time has passed, the program will continue to the next line of code. |

Comments:

//This is a comment | Comments are a great way to leave notes in your code explaining why you wrote it the way you did. You'll find many comments in the examples that further explain what the code is doing and why. Comments can be single line using //, or they can be multi-line using /* */. |

Coding Challenges

Coding Challenges: The Coding Challenges section is where you can find suggestions for changes to the circuit or code that will make the circuit more challenging. If you feel underwhelmed by the tasks in each circuit, visit the Coding Challenges section to push yourself to the next level.

| Challenge | Description |

|---|

| Persistence of Vision | Computer screens, movies and the lights in your house all flicker so quickly that they appear to be on all of the time but are actually blinking faster than the human eye can detect. See how much you can decrease the delay time in your program before the light appears to be on all the time but is still blinking.

|

| Morse Code | Try changing the delays and adding more digitalWrite() commands to make your program blink a message in Morse code. |

Troubleshooting

Troubleshooting: Last, each circuit has a Troubleshooting section with helpful tips and tricks to aid you in any problems you encounter along the way.

| Problem | Solution |

|---|

| I get an error when uploading my code | The most likely cause is that you have the wrong board selected in the Arduino IDE. Make sure you have selected Tools > Board > Arduino/Genuino Uno. |

| I still get an error when uploading my code | If you're sure you have the correct Board selected but you still can't upload, check that you have selected the correct Serial Port. You can change this in Tools > Serial Port >your_serial_port. |

| Which Serial Port is the right one? | Depending on how many devices you have plugged into your computer, you may have several active Serial Ports. Make sure you are selecting the correct one. A simple way to determine this is to look at your list of Serial Ports. Unplug your RedBoard from your computer. Look at the list again. Whichever Serial Port has disappeared from the list is the one you want to select once you plug your board back in to your computer.

|

| My code uploads, but my LED won’t turn on | LEDs will only work in one direction. Try taking it out of your breadboard, turning it 180 degrees, and reinserting it. |

| Still not working? | Jumper wires unfortunately can go "bad" from getting bent too much. The copper wire inside can break, leaving an open connection in your circuit. If you are certain that your circuit is wired correctly and that your code is error-free and uploaded but you are still encountering issues, try replacing one or more of the jumper wires for the component that is not working. |

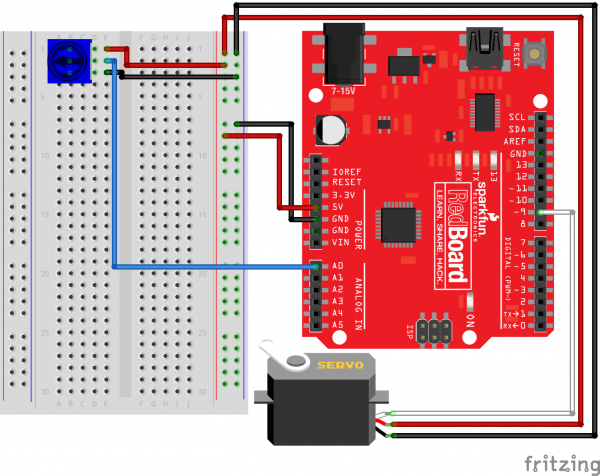

Circuit 2: Potentiometer

Potentiometers (also known as “pots” or “knobs”) are one of the basic inputs for electronics devices. By tracking the position of the knob with your RedBoard, you can make volume controls, speed controls, angle sensors and a ton of other useful inputs for your projects. In this circuit, you’ll use a potentiometer as an input device to control the speed at which your LED blinks.

![Tinker Kit Circuit 2]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 1x Red LED

- 1x 330Ω Resistor

- 7x Jumper Wires

- 1x Potentiometer

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

COM-09590

LEDs - those blinky things. A must have for power indication, pin status, opto-electronic sensors, and fun blinky displays. …

In stock

PRT-14490

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

New Components

Potentiometer

A potentiometer (trimpot for short) is a variable resistor. When powered with 5V, the middle pin outputs a voltage between 0V and 5V, depending on the position of the knob on the potentiometer. Internal to the trimpot is a single resistor and a wiper, which cuts the resistor in two and moves to adjust the ratio between both halves. Externally, there are usually three pins: two pins connect to each end of the resistor, while the third connects to the pot’s wiper.

![potentiometer]()

New Concepts

Analog vs. Digital

Understanding the difference between analog and digital is a fundamental concept in electronics.

We live in an analog world. There is an infinite number of colors to paint an object (even if the difference is indiscernible to our eye), an infinite number of tones we can hear, and an infinite number of smells we can smell. The common theme among all of these analog signals is their infinite possibilities.

Digital signals deal in the realm of the discrete or finite, meaning there is a limited set of values they can be. The LED from the previous circuit had only two states it could exist in, ON or OFF, when connected to a Digital Output.

Analog Inputs

So far, we’ve only dealt with outputs. The RedBoard also has inputs. Both inputs and outputs can be analog or digital. Based on our definition of analog and digital above, that means an analog input can sense a wide range of values versus a digital input, which can only sense two states.

You may have noticed some pins labeled Digital and some labeled Analog In on your RedBoard. There are only six pins that function as analog inputs; they are labeled A0–A5.

![analog pins vs digital pins]()

The six analog pins highlighted.

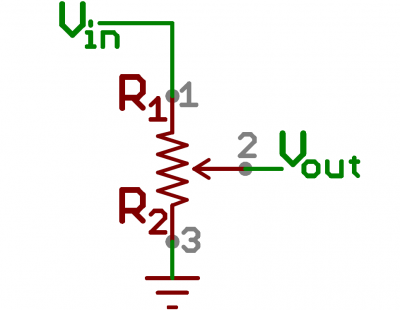

Voltage Divider

A voltage divider is a simple circuit that turns some voltage into a smaller voltage using two resistors. The following is a schematic of the voltage divider circuit. Schematics are a universally agreed upon set of symbols that engineers use to represent electric circuits.

![voltage divider]()

A potentiometer is a variable resistor that can be used to create an adjustable voltage divider.

![Schematic symbol for a potentiometer]()

A potentiometer schematic symbol where pins 1 and 3 are the resistor ends, and pin 2 connects to the wiper

If the outside pins connect to a voltage source (one to ground, the other to Vin), the output (Vout) at the middle pin will mimic a voltage divider. Turn the trimpot all the way in one direction, and the voltage may be zero; turned to the other side, the output voltage approaches the input. A wiper in the middle position means the output voltage will be half of the input.

Voltage dividers will be covered in more detail in the next circuit.

Hardware Hookup

The potentiometer has three legs. Pay close attention into which pins you’re inserting it on the breadboard, as they will be hard to see once inserted.

Potentiometers are not polarized. You can attach either of the outside pins to 5V and the opposite to GND. However, the values you get out of the trimpot will change based on which pin is 5V and which is GND.

![potentiometer_pinout]()

Ready to start hooking everything up? Check out the circuit diagram and hookup table below to see how everything is connected.

Circuit Diagram

![Activity 2: Potentiometer]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

| Component | RedBoard | Breadboard | Breadboard | Breadboard |

|---|

| Jumper Wire | 5V | 5V Rail ( + ) | | |

| Jumper Wire | GND | GND Rail ( - ) | | |

| LED | | A1 LED ( - ) | A2 LED ( + ) | |

330Ω Resistor

(orange, orange, brown) | | E2 | F2 | |

| Jumper Wire | | E1 | GND Rail ( - ) | |

| Jumper Wire | Digital Pin 13 | J2 | | |

| Potentiometer | | B25 | B26 | B27 |

| Jumper Wire | Analog Pin 0 (A0) | E26 | | |

| Jumper Wire | | E25 | 5V Rail ( + ) | |

| Jumper Wire | | E27 | GND Rail ( - ) | |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open the Sketch

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 2: Potentiometer

Changes how fast an LED connected to pin 13 blinks, based on a potentiometer connected to pin A0

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code

*/

int potPosition; //this variable will hold a value based on the position of the potentiometer

void setup()

{

Serial.begin(9600); //start a serial connection with the computer

pinMode(13, OUTPUT); //set pin 13 as an output that can be set to HIGH or LOW

}

void loop()

{

//read the position of the pot

potPosition = analogRead(A0); //set potPosition to a number between 0 and 1023 based on how far the knob is turned

Serial.println(potPosition); //print the value of potPosition in the serial monitor on the computer

//change the LED blink speed based on the trimpot value

digitalWrite(13, HIGH); // Turn on the LED

delay(potPosition); // delay for as many miliseconds as potPosition (0-1023)

digitalWrite(13, LOW); // Turn off the LED

delay(potPosition); // delay for as many miliseconds as potPosition (0-1023)

}

What You Should See

You should see the LED blink faster or slower in accordance with your potentiometer. The delay between each flash will change based on the position of the knob. If it isn’t working, make sure you have assembled the circuit correctly and verified and uploaded the code to your board, or see the Troubleshooting section.

![Tinker Kit Circuit 2]()

Program Overview

- Read the position of the potentiometer (from 0 to 1023) and store it in the variable

potPosition. - Turn the LED on.

- Wait from 0 to 1023 milliseconds, based on the position of the knob and the value of

potPosition. - Turn the LED off.

- Wait from 0 to 1023 milliseconds, based on the position of the knob and the value of

potPosition. - Repeat.

The Serial Monitor: The

Serial Monitor is one of the Arduino IDE's many great built-in tools. It can help you understand the values that your program is trying to work with, and it can be a powerful debugging tool when you run into issues where your code is not behaving the way you expected it to. This circuit introduces you to the Serial Monitor by showing you how to print the values from your potentiometer to it. To see these values, click the Serial Monitor button, found in the upper-right corner of the IDE in most recent versions. You can also select Tools > Serial Monitor from the menu.

![]()

You should then see numeric values print out on the monitor. Turn the potentiometer, and you should see the values change as well as the delay between each print.

![]()

If you are having trouble seeing the values, ensure that you have selected

9600 baud in the dropdown menu and have auto scroll checked.

Code to Note

| Code | Description |

|---|

Integer Variables:

int potPosition; | A variable is a placeholder for values that may change in your code. You must introduce, or "declare" variables before you use them. Here we're declaring a variable called potPosition of type int (integer). We will cover more types of variables in later circuits. Don't forget that variable names are case-sensitive! |

Serial Begin:

Serial.begin(9600); | Serial commands can be used to send and receive data from your computer. This line of code tells the RedBoard that we want to "begin" that communication with the computer, the same way we would say "Hi" to initiate a conversation. Notice that the baud rate, 9600, is the same as the one we selected in the monitor. This is the speed at which the two devices communicate, and it must match on both sides. |

Analog Input:

potPosition = analogRead(A0); | We use the analogRead() function to read the value on an analog pin. analogRead() takes one parameter, the analog pin you want to use, A0 in this case, and returns a number between 0 (0 volts) and 1023 (5 volts), which is then assigned to the variable potPosition. |

Serial Print:

Serial.println(potPosition); | This is the line that actually prints the trimpot value to the monitor. It takes the variable potPosition and prints whatever value it equals at that moment in the loop(). The ln at the end of print tells the monitor to print a new line at the end of each value; otherwise the values would all run together on one line. Try removing the ln to see what happens. |

Coding Challenges

| Challenge | Description |

|---|

| Changing the Range | Try multiplying, dividing or adding to your sensor reading so that you can change the range of the delay in your code. For example, can you multiply the sensor reading so that the delay goes from 0–2046 instead of 0–1023? |

| Adding More LEDs | Add more LEDs to your circuit. Don't forget the current limiting resistor for each one. Try making multiple LEDs blink at different rates by changing the range of each using multiplication or division. |

Troubleshooting

| Problem | Solution |

|---|

| The potentiometer always reads as 0 or 1023 | Make sure that your 5V, A0 and GND pins are properly connected to the three pins on your potentiometer. It is easy to misalign a wire with the actual trimpot pin. |

| No values in Serial Monitor | Make sure that you have selected the correct baud rate, 9600. Also ensure that you are on the correct Serial Port. The same Serial Port you use when uploading code to your board is the same Serial Port you use to print values to the Serial Monitor. |

Circuit 3: Photoresistor

In circuit 1B, you got to use a potentiometer, which varies resistance based on the twisting of a knob. In this circuit you’ll be using a photoresistor, which changes resistance based on how much light the sensor receives. Using this sensor you can make a simple night-light that turns on when the room gets dark and turns off when it is bright.

![Tinker Kit Circuit 3]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 7x Jumper Wires

- 1x Red LED

- 1x 330Ω Resistor

- 1x Photoresistor

- 1x 10kΩ Resistor

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

SEN-09088

This is a very small light sensor. A photocell changes (also called a [photodetector](http://en.wikipedia.org/wiki/Photodetec…

7In stock

COM-12062

We all know that you can never get too many LEDs. Don't worry, we've got you covered. This is a pack of basic red, yellow, bl…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

PRT-14490

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

In stock

PRT-14491

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

New Components

Photoresistor

Photoresistors, or photocells, are light-sensitive, variable resistors. As more light shines on the sensor’s head, the resistance between its two terminals decreases. They’re an easy-to-use component in projects that require ambient-light sensing.

![Photoresistor]()

New Concepts

Analog to Digital Conversion

The world we live in is analog, but the RedBoard lives in a digital world. In order to have the RedBoard sense analog signals, we must first pass them through an Analog to Digital Converter (or ADC). The six analog inputs (A0–A5) covered in the last circuit all use an ADC. These pins “sample” the analog signal and create a digital signal for the microcontroller to interpret. The “resolution” of this signal is based on the resolution of the ADC. In the case of the RedBoard, that resolution is 10-bit. With a 10-bit ADC, we get 2 ^ 10 = 1024 possible values, which is why the analog signal varies between 0 and 1023.

Voltage Divider Continued

Since the RedBoard can’t directly interpret resistance (rather, it reads voltage), we need to use a voltage divider to use our photoresistor, a part that doesn’t output voltage. The resistance of the photoresistor changes as it gets darker or lighter. That changes the amount of voltage that is read on the analog pin, which “divides” the voltage, 5V in this case. That divided voltage is then read on the analog to digital converter.

Left: A regular voltage divider circuit. Vout will be a constant voltage. Right: A variable voltage divider circuit. Vout will fluctuate as the resistance of the photoresistor changes.

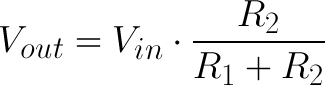

The voltage divider equation assumes that you know three values of the above circuit: the input voltage (Vin), and both resistor values (R1 and R2). Given those values, we can use this equation to find the output voltage (Vout):

![Vout = Vin * (R2 / (R1 + R2))]()

If R1 is a constant value (the resistor) and R2 fluctuates (the photoresistor), the amount of voltage measured on the Vout pin will also fluctuate.

Hardware Hookup

Note that the photoresistor is not polarized. It can be inserted in either direction.

Ready to start hooking everything up? Check out the circuit diagram and hookup table below to see how everything is connected.

Circuit Diagram

![Circuit_1C]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

| Component | RedBoard | Breadboard | Breadboard |

|---|

| Jumper Wire | 5V | 5V Rail ( + ) | |

| Jumper Wire | GND | GND Rail ( - ) | |

| LED | | A1 LED ( - ) | A2 LED ( + ) |

330Ω Resistor

(orange, orange, brown) | | E2 | F2 |

| Jumper Wire | | E1 | GND Rail ( - ) |

| Jumper Wire | Digital Pin 13 | J2 | |

| Photoresistor | | A26 | B25 |

10kΩ Resistor

(brown, black, orange) | | C26 | D27 |

| Jumper Wire | Analog Pin 0 (A0) | E26 | |

| Jumper Wire | | E25 | 5V Rail ( + ) |

| Jumper Wire | | E27 | GND Rail ( - ) |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open the Sketch

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 3: Photoresistor

Use a photoresistor to monitor how bright a room is, and turn an LED on when it gets dark.

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download drawings and code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code

*/

int photoresistor = 0; //this variable will hold a value based on the position of the knob

int threshold = 750; //if the photoresistor reading is below this value the light will turn on

void setup()

{

Serial.begin(9600); //start a serial connection with the computer

pinMode(13, OUTPUT); //set pin 13 as an output that can be set to HIGH or LOW

}

void loop()

{

//read the position of the knob

photoresistor = analogRead(A0); //set photoresistor to a number between 0 and 1023 based on how far the knob is turned

Serial.println(photoresistor); //print the value of photoresistor in the serial monitor on the computer

//if the photoresistor value is below the threshold turn the light on, otherwise turn it off

if (photoresistor < threshold){

digitalWrite(13, HIGH); // Turn on the LED

} else{

digitalWrite(13, LOW); // Turn off the LED

}

delay(100); //short delay to make the printout easier to read

}

What You Should See

The program stores the light level in a variable, photoresistor. Then, using an if/else statement, the program checks to see what it should do with the LED. If the variable is above the threshold (it’s bright), turn the LED off.

If the variable is below the threshold (it’s dark), turn the LED on. You now have just built your own night-light!

![Tinker Kit Circuit 3]()

Open the Serial Monitor in Arduino. The value of the photoresistor should be printed every so often. When the photoresistor value drops below the threshold value set in the code, the LED should turn on (you can cover the photoresistor with your finger to make the value drop).

Note: If the room you are in is very bright or dark, you may have to change the value of the “threshold” variable in the code to make your night-light turn on and off. See the Troubleshooting section for instructions.

Program Overview

- Store the light level in the variable

photoresistor. - If the value of

photoresistor is above the threshold (it’s bright), turn the LED off. - If the value of

photoresistor is below the threshold (it’s dark), turn the LED on.

Code to Note

| Code | Description |

|---|

If/else Statements:

if(logic statement) {

code to be run if the logic statement is true}

else {

code to be run if the logic statement is false

} | The if/else statement lets your code react to the world by running one set of code when the logic statement in the round brackets is true and another set of code when the logic statement is false. For example, this sketch uses an if statement to turn the LED on when it is dark, and turn the LED off when it is light. |

Logical Operators:

(photoresistor < threshold) | Programmers use logic statements to translate things that happen in the real world into code. Logic statements use logical operators such as 'equal to' (==), 'greater than' (>), and 'less than' (<), to make comparisons. When the comparison is true (e.g., 4 < 5) then the logic statement is true. When the comparison is false (e.g., 5 < 4) then the logic statement is false. This example is asking whether the variable photoresistor is less than the variable threshold. |

Coding Challenges

| Challenge | Description |

|---|

| Response Pattern | Right now your if statement turns the LED on when it gets dark, but you can also use the light sensor like a no-touch button. Try using digitalWrite() and delay() to make the LED blink a pattern when the light level drops, then calibrate the threshold variable in the code so that the blink pattern triggers when you wave your hand over the sensor. |

| Replace 10KΩ Resistor with LED | Alter the circuit be replacing the 10KΩ resistor with an LED (the negative leg should connect to GND). Now what happens when you place your finger over the photoresistor? This is a great way to see Ohm's law in action by visualizing the change in resistance's affect on the current flowing through the LED. |

Troubleshooting

| Problem | Solution |

|---|

| The light never turns on or always stays on | Start the Serial Monitor in Arduino. Look at the value that the photoresistor is reading in a bright room (e.g., 915). Cover the photoresistor, or turn the lights off. Then look at the new value that the photoresistor is reading (e.g., 550). Set the threshold in between these two numbers (e.g., 700) so that the reading is above the threshold when the lights are on and below the threshold when the lights are off. |

| Nothing is printing in the Serial Monitor | Try unplugging your USB cable and plugging it back in. In the Arduino IDE, go to Tools > Port, and make sure that you select the right port. |

Circuit 4: RGB Night-Light

In this circuit, you’ll take the night-light concept to the next level by adding an RGB LED, which is three differently colored Light-Emitting Diodes (LEDs) built into one component. RGB stands for Red, Green and Blue, and these three colors can be combined to create any color of the rainbow!

![alt text]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 12x Jumper Wires

- 1x LED - RGB Diffused Common Cathode

- 3x 330Ω Resistor

- 1x 10K Potentiometer

- 1x Photoresistor

- 1x 10kΩ Resistor

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

SEN-09088

This is a very small light sensor. A photocell changes (also called a [photodetector](http://en.wikipedia.org/wiki/Photodetec…

7In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

COM-09264

Ever hear of a thing called RGB? Red, Green, Blue? How about an RGB LED? These 5mm units have four pins - Cathode is the long…

2In stock

PRT-14490

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

In stock

PRT-14491

These are your run-of-the-mill 1/4 Watt, +/- 5% tolerance PTH resistors. Commonly used in breadboards and other prototyping a…

New Components

RGB LED

An RGB LED is actually three small LEDs — one red, one green and one blue — inside a normal LED housing. The RGB LED included in this kit has all the internal LEDs share the same ground wire, so there are four legs in total. To turn one color on, ensure ground is connected, then power one of the legs just as you would a regular LED. If you turn on more than one color at a time, you will see the colors start to blend together to form a new color.

![RGB LED]()

New Concepts

Analog Output (Pulse-width Modulation)

You can use the digitalWrite() command to turn pins on the RedBoard on (5V) or off (0V), but what if you want to output 2.5V? The RedBoard doesn’t have an Analog Output, but it is really good at switching some digital pins on and off fast enough to simulate an analog output. analogWrite() can output 2.5 volts by quickly switching a pin on and off so that the pin is only on 50 percent of the time (50% of 5V is 2.5V). By changing the percent of time that a pin is on, from 0 percent (always off) to 100 percent (always on), analogWrite() can output any voltage between 0 and 5V. This is what is known as pulse-width modulation (or PWM). By using PWM, you can create many different colors with the RGB LED.

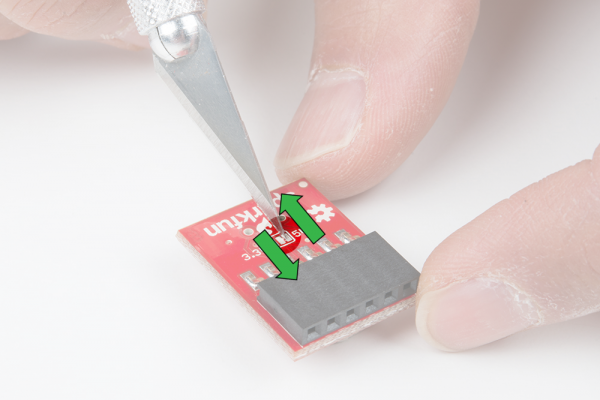

Digital (PWM~): Only a few of the pins on the RedBoard have the circuitry needed to turn on and off fast enough for PWM. These are pins

3, 5, 6, 9, 10 and 11. Each PWM pin is marked with a ~ on the board. Remember, you can only use

analogWrite() on these pins.

![]()

Creating Your Own Simple Functions

When programmers want to use a piece of code over and over again, they write a function. The simplest functions are just chunks of code that you give a name to. When you want to run that code, you can “call” the function by typing its name, instead of writing out all of the code. More complicated functions take and return pieces of information from the program (we call these pieces of information parameters). In this circuit, you’ll write functions to turn the RGB LED different colors by just typing that color’s name.

Hardware Hookup

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

Just like a regular LED, an RGB LED is polarized and only allows electricity to flow in one direction. Pay close attention to the flat edge and to the different length leads. Both are indicators to help orient the LED correctly.

![RGB LED Pins]()

Ready to start hooking everything up? Check out the circuit diagram and hookup table below to see how everything is connected.

Circuit Diagram

![Circuit_1D-RGB_Nightlight]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

| Component | RedBoard | Breadboard | Breadboard | Breadboard | Breadboard |

|---|

| RGB LED | | A5 (RED) | A4 (GND) | A3 (GREEN) | A2 (BLUE) |

330Ω Resistor

(orange, orange, brown) | | E2 | F2 | | |

330Ω Resistor

(orange, orange, brown) | | E3 | F3 | | |

330Ω Resistor

(orange, orange, brown) | | E5 | F5 | | |

| Jumper Wire | | E4 | GND Rail ( - ) | | |

| Jumper Wire | Digital Pin 9 | J5 | | | |

| Jumper Wire | Digital Pin 10 | J3 | | | |

| Jumper Wire | Digital Pin 11 | J2 | | | |

| Jumper Wire | 5V | 5V Rail ( + ) | | | |

| Jumper Wire | GND | GND Rail ( - ) | | | |

| Potentiometer | | B15 | B16 | B17 | |

| Jumper Wire | Analog Pin 1 (A1) | E16 | | | |

| Jumper Wire | | E15 | 5V Rail ( + ) | | |

| Jumper Wire | | E17 | GND Rail ( - ) | | |

| Photoresistor | | A26 | B25 | | |

10kΩ Resistor

(brown, black, orange) | | C26 | D27 | | |

| Jumper Wire | Analog Pin 0 (A0) | E26 | | | |

| Jumper Wire | | E25 | 5V Rail ( + ) | | |

| Jumper Wire | | E27 | GND Rail ( - ) | | |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open the Sketch

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 4: RGB Night-Light

Turns an RGB LED on or off based on the light level read by a photoresistor.

Change colors by turning the potentiometer.

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download drawings and code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code

*/

int photoresistor; //variable for storing the photoresistor value

int potentiometer; //variable for storing the photoresistor value

int threshold = 700; //if the photoresistor reading is lower than this value the light wil turn on

//LEDs are connected to these pins

int RedPin = 9;

int GreenPin = 10;

int BluePin = 11;

void setup() {

Serial.begin(9600); //start a serial connection with the computer

//set the LED pins to output

pinMode(RedPin,OUTPUT);

pinMode(GreenPin,OUTPUT);

pinMode(BluePin,OUTPUT);

}

void loop() {

photoresistor = analogRead(A0); //read the value of the photoresistor

potentiometer = analogRead(A1);

Serial.print("Photoresistor value:");

Serial.print(photoresistor); //print the photoresistor value to the serial monitor

Serial.print(" Potentiometer value:");

Serial.println(potentiometer); //print the photoresistor value to the serial monitor

if(photoresistor < threshold){ //if it's dark (the photoresistor value is below the threshold) turn the LED on

//These nested if staments check for a variety of ranges and

//call different functions based on the current potentiometer value.

//Those functions are found at the bottom of the sketch.

if(potentiometer > 0 && potentiometer <= 150)

red();

if(potentiometer > 150 && potentiometer <= 300)

orange();

if(potentiometer > 300 && potentiometer <= 450)

yellow();

if(potentiometer > 450 && potentiometer <= 600)

green();

if(potentiometer > 600 && potentiometer <= 750)

cyan();

if(potentiometer > 750 && potentiometer <= 900)

blue();

if(potentiometer > 900)

magenta();

}

else { //if it isn't dark turn the LED off

turnOff(); //call the turn off function

}

delay(100); //short delay so that the printout is easier to read

}

void red (){

//set the LED pins to values that make red

analogWrite(RedPin, 100);

analogWrite(GreenPin, 0);

analogWrite(BluePin, 0);

}

void orange (){

//set the LED pins to values that make orange

analogWrite(RedPin, 100);

analogWrite(GreenPin, 50);

analogWrite(BluePin, 0);

}

void yellow (){

//set the LED pins to values that make yellow

analogWrite(RedPin, 100);

analogWrite(GreenPin, 100);

analogWrite(BluePin, 0);

}

void green (){

//set the LED pins to values that make green

analogWrite(RedPin, 0);

analogWrite(GreenPin, 100);

analogWrite(BluePin, 0);

}

void cyan (){

//set the LED pins to values that make cyan

analogWrite(RedPin, 0);

analogWrite(GreenPin, 100);

analogWrite(BluePin, 100);

}

void blue (){

//set the LED pins to values that make blue

analogWrite(RedPin, 0);

analogWrite(GreenPin, 0);

analogWrite(BluePin, 100);

}

void magenta (){

//set the LED pins to values that make magenta

analogWrite(RedPin, 100);

analogWrite(GreenPin, 0);

analogWrite(BluePin, 100);

}

void turnOff (){

//set all three LED pins to 0 or OFF

analogWrite(RedPin, 0);

analogWrite(GreenPin, 0);

analogWrite(BluePin, 0);

}

What You Should See

This sketch is not dissimilar from the last. It reads the value from the photoresistor, compares it to a threshold value, and turns the RGB LED on or off accordingly. This time, however, we’ve added a potentiometer back into the circuit. When you twist the pot, you should see the color of the RGB LED change based on the pot’s value.

![alt text]()

Open the Serial Monitor. The value being read by the light sensor should be printed several times a second. When you turn out the lights or cover the sensor, the LED will shine whatever color your programmed in your color function. Next to the light value, you’ll see the potentiometer value print out as well.

Note: If the room you are in is very bright or dark, you may have to change the value of the “threshold” variable in the code to make your night-light turn on and off. See the Troubleshooting section for instructions.

Program Overview

- Store the light level from pin A0 in the variable

photoresistor. - Store the potentiometer value from pin A1 in the variable

potentiometer. - If the light level variable is above the

threshold, call the function that turns the RGB LED off. - If the light level variable is below the

threshold, call one of the color functions to turn the RGB LED on. - If

potentiometer is between 0 and 150, turn the RGB LED on red. - If

potentiometer is between 151 and 300, turn the RGB LED on orange. - If

potentiometer is between 301 and 450, turn the RGB LED on yellow. - If

potentiometer is between 451 and 600, turn the RGB LED on green. - If

potentiometer is between 601 and 750, turn the RGB LED on cyan. - If

potentiometer is between 751 and 900, turn the RGB LED on blue. - If

potentiometer is greater than 900, turn the RGB LED on magenta.

Code to Note

| Code | Description |

|---|

Analog Output (PWM):

analogWrite(RedPin, 100); | The analogWrite() function outputs a voltage between 0 and 5V on a pin. The function breaks the range between 0 and 5V into 255 little steps. Note that we are not turning the LED on to full brightness (255) in this code so that the night-light is not too bright. Feel free to change these values and see what happens. |

Nested if Statements:

if(logic statement) {

if(logic statement) {

code to be run if the logic statement is true}

if(logic statement) {

code to be run if the logic statement is true}

} | A nested if statement is one or more if statements "nested" inside of another if statement. If the parent if statement is true, then the code looks at each of the nested if statements and executes any that are true. If the parent if statement is false, then none of the nested statements will execute. |

More Logical Operators:

if(potentiometer > 0 && potentiometer <= 150) | These if statements are checking for two conditions by using the AND (&&) operator. In this line, the if statement will only be true if the value of the variable potentiometer is greater than 0 AND if the value is less than or equal to 150. By using &&, the program allows the LED to have many color states. |

Defining a Function:

void function_name () {

code to run inside function

}

| This simple version of a function executes the code inside the curly brackets whenever the name is written in the main program. |

Calling a Function:

function_name();

| Calls a function that you have created.

In a later circuit, you will learn how to make more complicated functions that take data from the main program (these pieces of data are called parameters).

|

Coding Challenges

| Challenge | Description |

|---|

| Add more colors | You can create many more colors with the RGB LED. Use the analogWrite() function to blend different values of red, green and blue together to make even more colors. You can divide the potentiometer value up more and make more nested if statements so that you can have more colors as you twist the knob. |

| Multi color blink | Try using delays and multiple color functions to have your RGB LED change between multiple colors. |

| Change the threshold | Try setting your threshold variable by reading the value of a potentiometer with analogRead(). By turning the potentiometer, you can then change the threshold level and adjust your night-light for different rooms. |

| Fading the LED | Try using a loop with the analogWrite() to get your LED to pulse gently or smoothly transition between colors. |

Troubleshooting

| Problem | Solution |

|---|

| The LED never turns on or off | Open the Serial Monitor in Arduino and make sure that your photoresistor is returning values between 0 and 1023. Try covering the photoresistor; the values should change. If they do not change, check the wiring of the photoresistor.

If your photoresistor is working correctly, make sure that your threshold variable sits in between the value that the photoresistor reads when it is bright and the value that the photoresistor reads when it is dark (e.g., bright = 850, dark = 600, threshold = 700).

|

| My LED doesn’t show the colors that I expect | Make sure that all three of the pins driving your RGB LED are set to OUTPUT, using the pinMode() command in the setup section of the code. Then make sure that each LED is wired properly. |

| Nothing is printing in the Serial Monitor | Try unplugging your USB cable and plugging it back in. In the Arduino IDE, go to Tools > Port, and make sure that you select the right port. |

Circuit 5: Buzzer

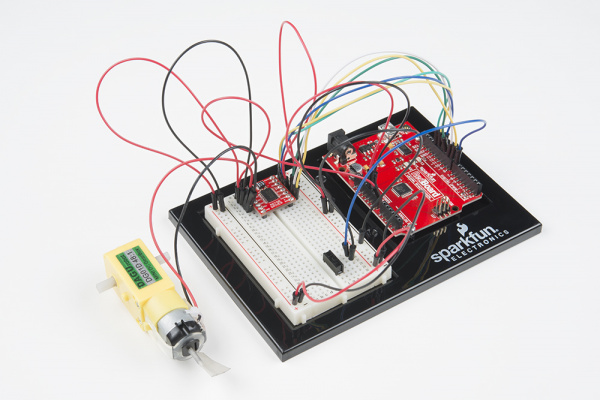

In this circuit, you’ll use the RedBoard and a small buzzer to make music, and you’ll learn how to program your own songs using arrays.

![alt text]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 4x Jumper Wires

- 1x 10K Potentiometer

- 1x Buzzer

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

COM-07950

We drove it directly from a 5V PIC to generate the tones for our Simon demonstration game.

5New Components

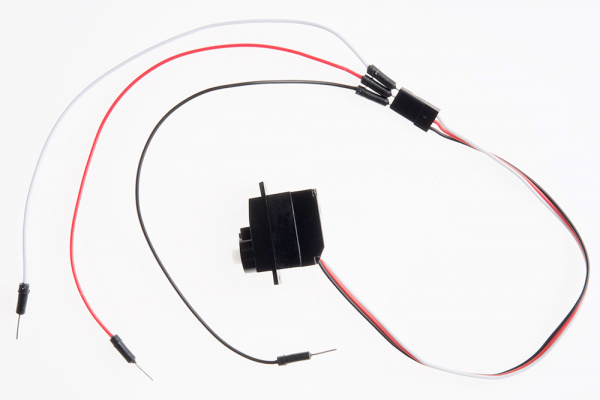

Buzzer

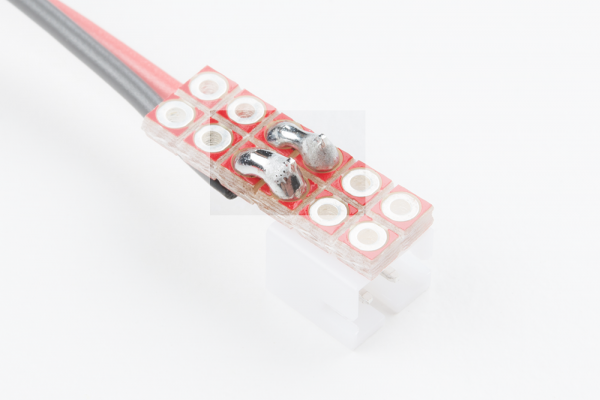

The buzzer uses a small magnetic coil to vibrate a metal disc inside a plastic housing. By pulsing electricity through the coil at different rates, different frequencies (pitches) of sound can be produced. Attaching a potentiometer to the output allows you to limit the amount of current moving through the buzzer and lower its volume.

![buzzer]()

New Concepts

Reset Button

The RedBoard has a built-in reset button. This button will reset the board and start the code over from the beginning, running what is in setup() and then loop().

![reset button]()

Tone Function

To control the buzzer, you will use the tone function. This function is similar to PWM in that it generates a wave that is of a certain frequency on the specified pin. The frequency and duration can both be passed to the tone() function when calling it. To turn the tone off, you need to call noTone() or pass a duration of time for it to play and then stop. Unlike PWM, tone() can be used on any digital pin.

Arrays

Arrays are used like variables, but they can store multiple values. The simplest array is just a list. Imagine that you want to store the frequency for each note of the C major scale. We could make seven variables and assign a frequency to each one, or we could use an array and store all seven in the same array, as shown below. To refer to a specific value in the array, an index number is used. Arrays are indexed from 0. For example, to call the first element in the array, use array_name[0];; to call the second element, use array_name[1]; and so on.

| Musical Note | Frequency (Hz) | Using Variables | Using an Array |

|---|

| A | 220 | aFrequency | frequency[0] |

| B | 247 | bFrequency | frequency[1] |

| C | 261 | cFrequency | frequency[2] |

| D | 294 | dFrequency | frequency[3] |

| E | 330 | eFrequency | frequency[4] |

| F | 349 | fFrequency | frequency[5] |

| G | 392 | gFrequency | frequency[6] |

Hardware Hookup

| Polarized Components | Pay special attention to the component’s markings indicating how to place it on the breadboard. Polarized components can only be connected to a circuit in one direction. |

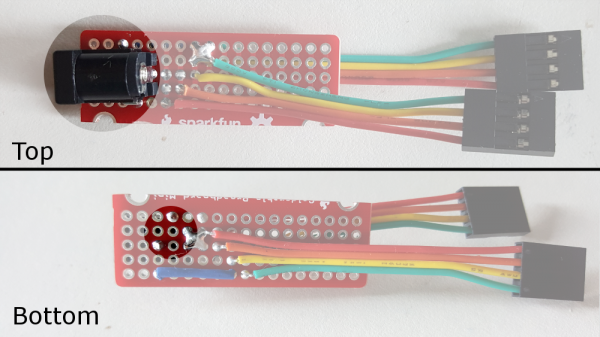

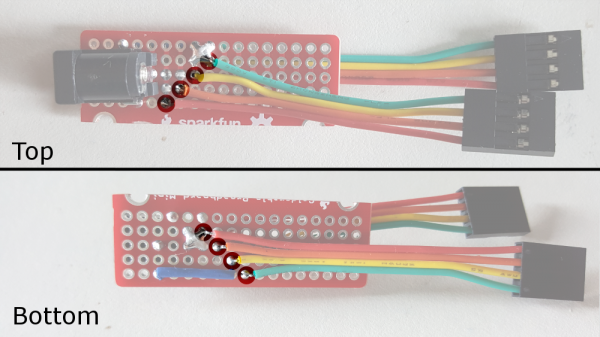

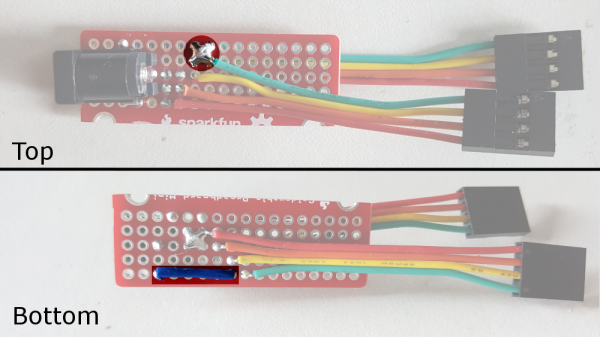

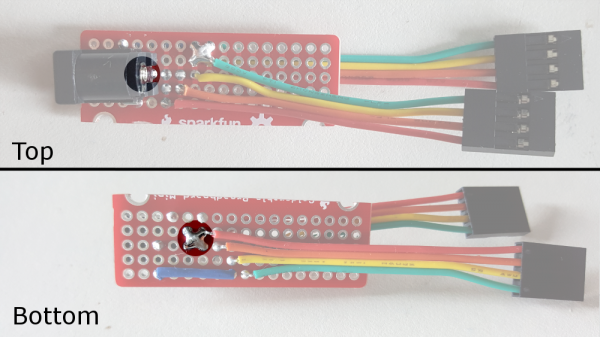

The buzzer is polarized. To see which leg is positive and which is negative, flip the buzzer over and look at the markings underneath. Keep track of which pin is where, as they will be hard to see once inserted into the breadboard. There is also text on the positive side of the buzzer, along with a tiny (+) symbol.

Volume Knob

All of the circuits in Project 2 make use of a potentiometer as a rudimentary volume knob. Notice that only two of the potentiometer’s legs are used in these circuits. In these instances, the potentiometer is acting as a variable resistor, limiting the amount of current flowing to the speaker and thus affecting the volume as you turn the knob. This is similar to the current-limiting resistor used to limit current to the LED in circuit 1A — only this time the resistance is variable.

Ready to start hooking everything up? Check out the circuit diagram and hookup table below to see how everything is connected.

Circuit Diagram

![Circuit_2A_buzzer]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

| Component | RedBoard | Breadboard | Breadboard | Breadboard |

|---|

| Buzzer | | J1 (Buzzer + ) | J3 (Buzzer - ) | |

| Potentiometer | | B1 | B2 | B3 |

| Jumper Wire | GND | GND Rail ( - ) | | |

| Jumper Wire | Digital Pin 10 | F1 | | |

| Jumper Wire | | E2 | GND Rail ( - ) | |

| Jumper Wire | | E1 | F3 |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open the Sketch

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 5: Buzzer

Play notes using a buzzer connected to pin 10

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download drawings and code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code/

*/

int speakerPin = 10; //the pin that buzzer is connected to

void setup()

{

pinMode(speakerPin, OUTPUT); //set the output pin for the speaker

}

void loop()

{

play('g', 2); //ha

play('g', 1); //ppy

play('a', 4); //birth

play('g', 4); //day

play('C', 4); //to

play('b', 4); //you

play(' ', 2); //pause for 2 beats

play('g', 2); //ha

play('g', 1); //ppy

play('a', 4); //birth

play('g', 4); //day

play('D', 4); //to

play('C', 4); //you

play(' ', 2); //pause for 2 beats

play('g', 2); //ha

play('g', 1); //ppy

play('G', 4); //birth

play('E', 4); //day

play('C', 4); //dear

play('b', 4); //your

play('a', 6); //name

play(' ', 2); //pause for 2 beats

play('F', 2); //ha

play('F', 1); //ppy

play('E', 4); //birth

play('C', 4); //day

play('D', 4); //to

play('C', 6); //you

while(true){} //get stuck in this loop forever so that the song only plays once

}

void play( char note, int beats)

{

int numNotes = 14; // number of notes in our note and frequency array (there are 15 values, but arrays start at 0)

//Note: these notes are C major (there are no sharps or flats)

//this array is used to look up the notes

char notes[] = { 'c', 'd', 'e', 'f', 'g', 'a', 'b', 'C', 'D', 'E', 'F', 'G', 'A', 'B', ' '};

//this array matches frequencies with each letter (e.g. the 4th note is 'f', the 4th frequency is 175)

int frequencies[] = {131, 147, 165, 175, 196, 220, 247, 262, 294, 330, 349, 392, 440, 494, 0};

int currentFrequency = 0; //the frequency that we find when we look up a frequency in the arrays

int beatLength = 150; //the length of one beat (changing this will speed up or slow down the tempo of the song)

//look up the frequency that corresponds to the note

for (int i = 0; i < numNotes; i++) // check each value in notes from 0 to 14

{

if (notes[i] == note) // does the letter passed to the play function match the letter in the array?

{

currentFrequency = frequencies[i]; // Yes! Set the current frequency to match that note

}

}

//play the frequency that matched our letter for the number of beats passed to the play function

tone(speakerPin, currentFrequency, beats * beatLength);

delay(beats* beatLength); //wait for the length of the tone so that it has time to play

delay(50); //a little delay between the notes makes the song sound more natural

}

/* CHART OF FREQUENCIES FOR NOTES IN C MAJOR

Note Frequency (Hz)

c 131

d 147

e 165

f 175

g 196

a 220

b 247

C 262

D 294

E 330

F 349

G 392

A 440

B 494

*/

What You Should See

When the program begins, a song will play from the buzzer once. To replay the song, press the reset button on the RedBoard. Use the potentiometer to adjust the volume.

![alt text]()

Program Overview

Inside the main loop:

- Play the first note for x number of beats using the play function.

- (Inside the play function:) Take the note passed to the play function and compare it to each letter in the notes array. When you find a note that matches, remember the index position of that note (e.g., 6th entry in the notes array).

- Get a frequency from the frequency array that has the same index as the note that matched (e.g., the 6th frequency).

- Play that frequency for the number of beats passed to the play function.

- Play the second note using the play function

…and so on.

Code to Note

| Code | Description |

|---|

Character Variables:

void play( char note, int beats) | The char, or character, variable to store character values. For example, in this sketch, the play() function gets passed two variables, a character variable that represents the mucial note we want to play and an integer variable that represents how long to play that note. A second array takes the character variable and associates a frequency value to it. This makes programming a song easier as you can just reference the character and not the exact frequency. |

Tone Function:

tone(pin, frequency, duration); | The tone() function will pulse power to a pin at a specific frequency. The duration controls how long the sound will play. Tone can be used on any digital pin. |

Declaring an Array:

arrray_name[array_size]; or arrray_name[] = {array elements}; | To declare an array, you must give it a name, then either tell Arduino how many positions the array will have or assign a list of values to the array. |

Calling an Array:

array_name[index #]; | To call one of the values in an array, simply type the name of the array and the index of the value. You can use a variable instead of a number in between the square brackets. Don't forget the index starts at 0, not 1, so to call the first element, use array_name[0];. |

Coding Challenges

| Challenge | Description |

|---|

| Change the tempo of the song | Experiment with the beatLength; variable to change the tempo of the song. |

| Make your own song | Try changing the notes to make a different song. Spaces "" can be used for rests in the song. |

Troubleshooting

| Problem | Solution |

|---|

| The song is too quiet or too loud | Turn the potentiometer to adjust the volume. |

| No sound is playing | Try pressing the reset button on the RedBoard. If that doesn’t work, check your wiring of the buzzer. It's easy to misalign a pin with a jumper wire. |

Circuit 6: Digital Trumpet

Learn about digital inputs and buttons as you build your own digital trumpet!

![alt text]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 10x Jumper Wires

- 1x 10K Potentiometer

- 1x Buzzer

- 1x Green Push Button

- 1x Yellow Push Button

- 1x Red Push Button

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

23In stock

PRT-12002

This is your tried and true white solderless breadboard. It has 2 power buses, 10 columns, and 30 rows - a total of 400 tie i…

35In stock

COM-09806

There are lots of trimpots out there. Some are very large, some so small they require a screwdriver. Here at SparkFun, we jus…

6In stock

PRT-11026

If you need to knock up a quick prototype there's nothing like having a pile of jumper wires to speed things up, and let's fa…

20In stock

COM-07950

We drove it directly from a 5V PIC to generate the tones for our Simon demonstration game.

5In stock

PRT-14460

This is a simple 4-pack of momentary, multicolor buttons, great for all sorts of projects! Unlike previous iterations of mult…

New Components

Buttons

Buttons, also known as momentary switches, are switches that only remain in their on state as long as they’re being actuated, or pressed. Most often momentary switches are best used for intermittent user-input cases: reset button and keypad buttons. These switches have a nice, tactile, “clicky” feedback when you press them.

![multicolored buttons]()

Note that the different colors are just aesthetic. All of the buttons included behave the same no matter their color.

New Concepts

Binary Number System

Number systems are the methods we use to represent numbers. We’ve all been mostly operating within the comfy confines of a base-10 number system, but there are many others. The base-2 system, otherwise known as binary, is common when dealing with computers and electronics. There are really only two ways to represent the state of anything: ON or OFF, HIGH or LOW, 1 or 0. And so, almost all electronics rely on a base-2 number system to store and manipulate numbers. The heavy reliance electronics places on binary numbers means it’s important to know how the base-2 number system works.

Digital Input

In circuit 1A, you worked with digital outputs. This circuit focuses on digital inputs. Digital inputs only care if something is in one of two states: TRUE or FALSE, HIGH or LOW, ON or OFF. Digital inputs are great for determining if a button has been pressed or if a switch has been flipped.

Pull-up Resistors

A pull-up resistor is a small circuit that holds the voltage HIGH (5V) on a pin until a button is pressed, pulling the voltage LOW (0V). The most common place you will see a pull-up resistor is when working with buttons. A pull-up resistor keeps the button in one state until it is pressed. The RedBoard has built-in pull-up resistors, but they can also be added to a circuit externally. This circuit uses the internal pull-up resistors, covered in more detail in the Code to Note section.

Hardware Hookup

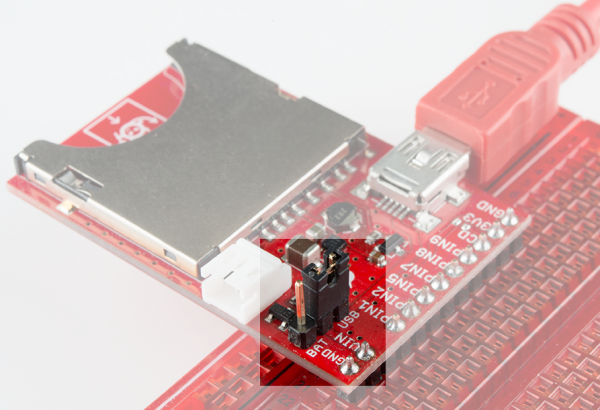

Buttons are not polarized. However, they do merit a closer look. Buttons make momentary contact from one connection to another, so why are there four legs on each button? The answer is to provide more stability and support to the buttons in your breadboard circuit. Each row of legs is connected internally. When the button is pressed, one row connects to the other, making a connection between all four pins.

![button pins explained]()

If the button’s legs don’t line up with the slots on the breadboard, rotate it 90 degrees.

Ready to start hooking everything up? Check out the circuit diagram and hookup table below to see how everything is connected.

Circuit Diagram

![Circuit_2B_trumpet]()

Having a hard time seeing the circuit? Click on the image for a closer look.

Hookup Table

| Component | RedBoard | Breadboard | Breadboard | Breadboard |

|---|

| Buzzer | | J1 (Buzzer + ) | J3 (Buzzer - ) | |

| Potentiometer | | B1 | B2 | B3 |

| Jumper Wire | GND | GND Rail ( - ) | | |

| Jumper Wire | Digital Pin 10 | F1 | | |

| Jumper Wire | | E2 | GND Rail ( - ) | |

| Jumper Wire | | E1 | F3 | |

| Push Button | | D16/D18 | G16/G18 | |

| Push Button | | D22/D24 | G22/G24 | |

| Push Button | | D28/D30 | G28/G30 | |

| Jumper Wire | Digital Pin 4 | J18 | | |

| Jumper Wire | Digital Pin 3 | J24 | | |

| Jumper Wire | Digital Pin 2 | J30 | | |

| Jumper Wire | | J16 | GND Rail ( - ) | |

| Jumper Wire | | J22 | GND Rail ( - ) | |

| Jumper Wire | | J28 | GND Rail ( - ) | |

In the table, polarized components are shown with a warning triangle and the whole row highlighted yellow.

Open the Sketch

Copy and paste the following code into the Arduino IDE. Hit upload, and see what happens!

language:cpp

/*

SparkFun Tinker Kit

Circuit 6: Digital Trumpet

Use 3 buttons plugged to play musical notes on a buzzer.

This sketch was written by SparkFun Electronics, with lots of help from the Arduino community.

This code is completely free for any use.

View circuit diagram and instructions at: https://learn.sparkfun.com/tutorials/activity-guide-for-sparkfun-tinker-kit/

Download drawings and code at: https://github.com/sparkfun/SparkFun_Tinker_Kit_Code/

*/

//set the pins for the button and buzzer

int firstKeyPin = 2;

int secondKeyPin = 3;

int thirdKeyPin = 4;

int buzzerPin = 10;

void setup() {

//set the button pins as inputs

pinMode(firstKeyPin, INPUT_PULLUP);

pinMode(secondKeyPin, INPUT_PULLUP);

pinMode(thirdKeyPin, INPUT_PULLUP);

//set the buzzer pin as an output

pinMode(buzzerPin, OUTPUT);

}

void loop() {

if(digitalRead(firstKeyPin) == LOW){ //if the first key is pressed

tone(buzzerPin, 262); //play the frequency for c

}

else if(digitalRead(secondKeyPin) == LOW){ //if the second key is pressed

tone(buzzerPin, 330); //play the frequency for e

}

else if(digitalRead(thirdKeyPin) == LOW){ //if the third key is pressed

tone(buzzerPin, 392); //play the frequency for g

}

else{

noTone(buzzerPin); //if no key is pressed turn the buzzer off

}

}

/*

note frequency

c 262 Hz

d 294 Hz

e 330 Hz

f 349 Hz

g 392 Hz

a 440 Hz

b 494 Hz

C 523 Hz

*/

What You Should See

Different tones will play when you press different keys. Turning the potentiometer will adjust the volume.

![alt text]()

Program Overview

- Check to see if the first button is pressed.

- If it is, play the frequency for c.

- If it isn’t, skip to the next else if statement.

- Check to see if the second button is pressed.

- If it is, play the frequency for e.

- If it isn’t, skip to the next else if statement.

- Check to see if the second button is pressed.

- If it is, play the frequency for g.

- If it isn’t, skip to the next else if statement.

- If none of the if statements are true

- Turn the buzzer off.

Code to Note

| Code | Description |

|---|

Internal Pull-Up Resistor:

pinMode(firstKeyPin, INPUT_PULLUP); | To declare a standard input, use the line pinMode(pin_name, INPUT). If you would like to use one of the RedBoard's built-in pull-up 20kΩ resistors, it would look like this: pinMode(firstKeyPin, INPUT_PULLUP);. The advantage of external pull-ups is being able to choose a more exact value for the resistor. |

Digital Input:

digitalRead(pin); | Check to see if an input pin is reading HIGH (5V) or LOW (0V). Returns TRUE (1) or FALSE (0) depending on the reading. |

Is Equal to:

if(digitalRead(firstKeyPin) == LOW) | This is another logical operator. The 'is equal to' symbol (==) can be confusing. Two equals signs are equivalent to asking, "Are these two values equal to one another?" On the other hand, one equals sign in code is assigning a particular variable to a value. Don't forget to add the second equals sign if you are comparing two values. |

Coding Challenges

| Challenge | Description |

|---|

| Change the key of each button | Use the frequency table in the comment section at the end of the code to change the notes that each button plays. |

| Play more than three notes with if statements | By using combinations of buttons, you can play up to seven notes of the scale. You can do this in a few ways. To get more practice with if statements, try adding seven if statements and using the Boolean AND (&&) operator to represent all of the combinations of keys. |

| Play more than three notes with binary math | You can use a clever math equation to play more than three notes with your three keys. By multiplying each key by a different number, then adding up all of these numbers, you can make a math equation that produces a different number for each combination of keys. |

Troubleshooting

| Problem | Solution |

|---|

| The buzzer is too loud or too quiet | Turn the potentiometer to adjust the volume. |

| The RedBoard thinks one key is always pressed | Check your wiring. You may have ground and 5V backward if one or more buttons behave as though they're pressed all the time. |

| The buttons are not working | First, make sure that the wiring is correct. It is easy to misalign a wire with a button leg. Second, make sure that you have declared your buttons as inputs and have enabled the internal pull-up resistors with INPUT_PULLUP. |

Circuit 7: Simon Says Game

The Simon Says game uses LEDs to flash a pattern, which the player must remember and repeat using four buttons. The classic Simon game has been a hit since the 1980s. Now you can build your own!

![alt text]()

Parts Needed

You will need the following parts:

- 1x Breadboard

- 1x SparkFun RedBoard

- 16x Jumper Wires

- 4x 330Ω Resistor

- 1x 10K Potentiometer

- 1x Buzzer

- 1x Blue LED

- 1x Blue Push Button

- 1x Green LED

- 1x Green Push Button

- 1x Yellow LED

- 1x Yellow Push Button

- 1x Red LED

- 1x Red Push Button

Didn’t Get the Tinker Kit?

If you are conducting this experiment and didn’t get the Tinker Kit, we suggest using these parts:

In stock

DEV-13975

At SparkFun we use many Arduinos and we're always looking for the simplest, most stable one. Each board is a bit different an…

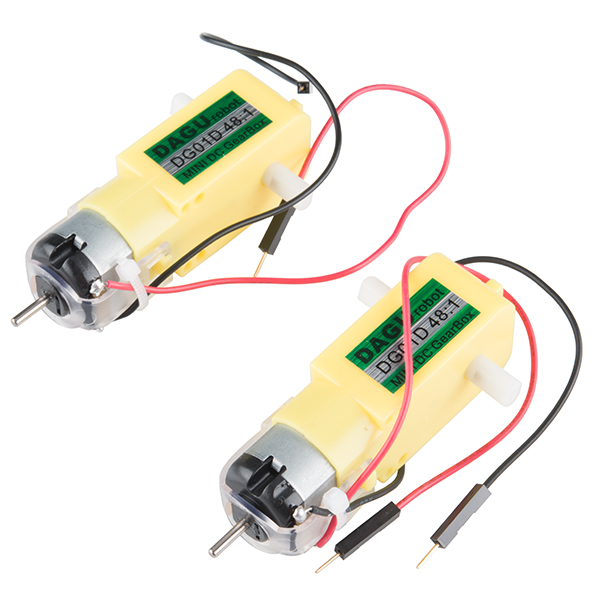

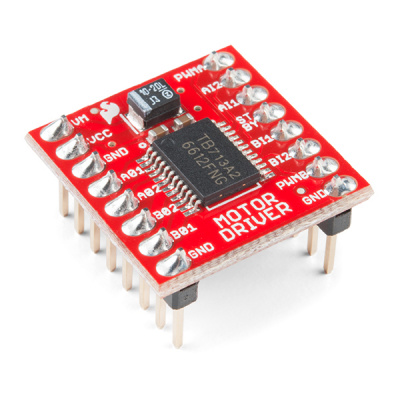

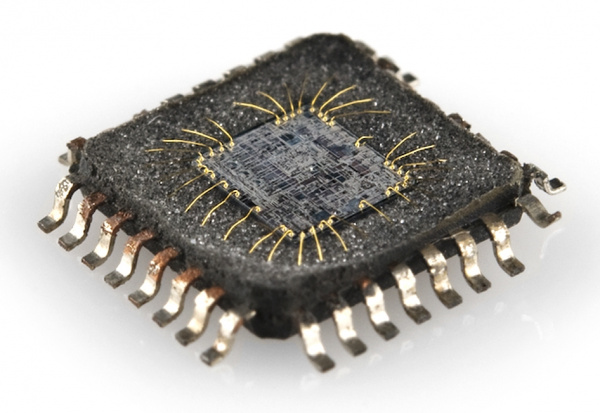

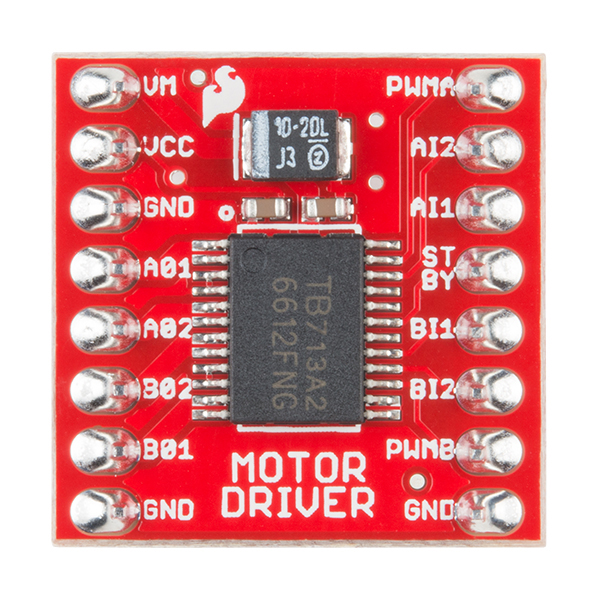

23In stock